Steel and Manufacturing

Enhancing Steel Industry Applications: Utilizing Lead Screws, Ball Screws, and Linear Actuators

In the steel industry, the utilization of lead screws, ball screws, and linear actuators significantly contributes to enhancing efficiency, precision, and safety across various applications. Let's explore how these technologies are employed in laser cutting, fabrication, metal forming, hardening, melting, and forging equipment, as well as stamping processes:

Laser Cutting

Lead screws, ball screws, and linear actuators play crucial roles in laser cutting machines, which are essential for precision cutting of steel sheets and plates. Lead screws facilitate controlled linear motion of the cutting head, ensuring precise positioning and movement along the cutting path. Ball screws provide smooth and precise rotational movement in the positioning systems of laser cutting machines, enabling accurate alignment and orientation of the cutting tool. Linear actuators drive vertical and horizontal movement in the workpiece handling systems, allowing for flexible and adaptable positioning of steel materials during the cutting process.

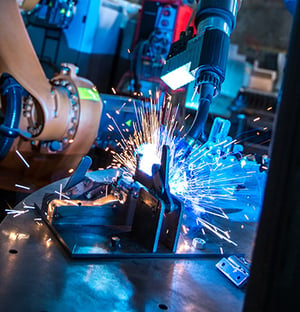

Fabrication

In steel fabrication processes, lead screws, ball screws, and linear actuators are utilized in various equipment and machinery for shaping and assembling steel components. Lead screws enable controlled linear motion in cutting, drilling, and milling machines, facilitating precise material removal and shaping operations. Ball screws provide smooth and precise rotational movement in bending and forming equipment, allowing for accurate bending angles and shapes to be achieved. Linear actuators drive vertical and horizontal movement in welding and assembly fixtures, ensuring accurate positioning and alignment of steel parts during fabrication processes.

Metal Forming

Lead screws, ball screws, and linear actuators are integral components in metal forming machinery, which is essential for shaping steel into desired forms and structures. Lead screws facilitate controlled linear motion in presses and stamping machines, enabling precise application of force to deform steel materials into specific shapes and sizes. Ball screws provide smooth and precise rotational movement in roll forming and extrusion equipment, allowing for accurate shaping and profiling of steel profiles and sections. Linear actuators drive vertical and horizontal movement in bending and shearing machines, ensuring accurate positioning and alignment of steel materials during forming operations.

Hardening, Melting, and Forging Equipment

In hardening, melting, and forging processes, lead screws, ball screws, and linear actuators are utilized in equipment and machinery for heating, shaping, and manipulating steel materials. Lead screws facilitate controlled linear motion in induction heating and quenching systems, ensuring precise positioning and movement of steel workpieces during heat treatment processes. Ball screws provide smooth and precise rotational movement in forging presses and rolling mills, enabling accurate shaping and deformation of steel materials under high temperatures and pressures. Linear actuators drive vertical and horizontal movement in die casting and extrusion machines, ensuring precise positioning and alignment of steel materials during forming and shaping operations.

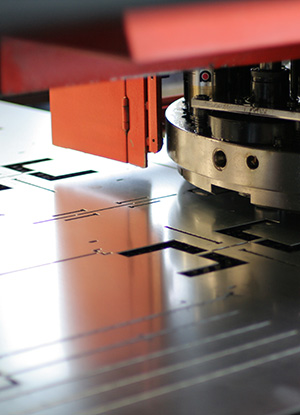

Stamping

In stamping processes, lead screws, ball screws, and linear actuators are essential components in stamping presses and die sets, which are used for shaping and cutting steel materials into desired shapes and sizes. Lead screws facilitate controlled linear motion in the ram of stamping presses, ensuring precise application of force to the stamping dies for accurate shaping and cutting of steel parts. Ball screws provide smooth and precise rotational movement in the positioning systems of stamping dies, allowing for accurate alignment and orientation of the dies relative to the workpiece. Linear actuators drive vertical and horizontal movement in the feeding and ejection systems, ensuring accurate positioning and movement of steel materials during the stamping process.

Lead screws, ball screws, and linear actuators are essential components that contribute to the efficiency, precision, and safety of various steel industry applications, including laser cutting, fabrication, metal forming, hardening, melting, and forging equipment, as well as stamping processes. Their versatility, reliability, and precision control capabilities make them indispensable for optimizing production workflows, ensuring product quality, and enhancing workplace safety in steel manufacturing environments.

Speak to an Application Engineer

Our application engineers are here to help you plan, customize and select the optimal linear motion components for your additive manufacturing application.

Our Products

Helix Linear Technologies offers a wide range of linear motion products that are designed to make your next food and beverage handling application a success. Not sure what you need? No problem. We're here to help guide you every step of the way.

Ball Screw Assemblies

Linear Actuators

Linear Guidance

Suggested Reading

Tap into our liner motion expertise in the food and beverage application space. Click to learn how the smooth, reliable movement of our precision lead screw and ball screw assemblies, and linear actuators can optimize your application success.

Linear Motion: A Driving Force in Industry Productivity

Downloads

3D Printing Case Study

3D Printing Case Study

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod.

Lead Screw Catalog

Lead Screw Catalog

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod.

Profile Rail Linear Actuator Catalog

Profile Rail Linear Actuator Catalog

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod.