Frequently Asked Questions

Have a question? We are here to help.

Can Helix manufacture a screw with a larger drive end than the screw diameter?

Yes, the rolling process lends itself very well to manufacturing lead screws that have larger dimensions on the drive end than the screw diameter. This helps to avoid using weaker two-piece designs. This picture shows several examples of single piece screws.

Yes, the rolling process lends itself very well to manufacturing lead screws that have larger dimensions on the drive end than the screw diameter. This helps to avoid using weaker two-piece designs. This picture shows several examples of single piece screws.

Are Helix Linear Technologies lead screw assemblies clean room compatible?

The class of clean room in which the lead screw will be used will determine its suitability. It is acceptable to use most lead screw assemblies in a class 1000 clean room with no modifications. When using a PTFE coating, Helix H10X is best to be used in these environments because it passes out-gassing and particule tests.

Can lead screw assemblies be used in harsh environments?

Helix Linear lead screw assemblies do not have any rolling elements so they are forgiving of many dust and dirty environments. The sliding friction allows operation in tough conditions such as paper handling, wood and metal routers, engravers and food processing equipment.

What do the terms "G" and "C" mean when referring to acme screw threads?

The ANSI standard for acme screw threads provides for two classes of fit, General Purpose (G) and Centralizing (C). The General Purpose fit provides for clearance on the major diameter and minor diameter while the screw and nut contact interface takes place on the thread flanks. The Centralizing fit provides for the same thread flank contact while simultaneously contacting on the major diameters. For applications of purely axial loading, there is little difference between the two. Centralizing fits may be preferred for applications that have loads transverse to the screw axis because the transverse loads are partially supported by the thread major diameters that act as radial bearings.

The acme thread form, established over 100 years ago, replaced square thread screws, which had straight-sided flanks and were difficult to manufacture.

There are three main classes of acme thread forms: general purpose (G), centralizing (C), and stub acme. The General Purpose and Centralizing thread forms have a nominal depth of thread of 0.50 × pitch and have a 29° included thread angle. Compared to general-purpose thread forms, centralizing threads are manufactured with tighter tolerances and reduced clearance on the major diameter.

Stub acme threads follow the same basic design but have a thread depth less than one half the pitch.

If an acme nut is side loaded with a radial load, a “G” class will “wedge” when the nut thread flanks come in contact with the screw thread flanks. To prevent wedging, less clearance and tighter tolerances are allowed between the major diameter of the nut and the major diameter of the screw.

CAUTION: Although a side load will not cause a centralizing thread to wedge, the nut is not designed to operate with a side load such as a pulley, drive belt, etc.

What is the best way to secure something to a lead screw nut?

MOUNTING AND PINNING OF FLANGES

For PowerAC™ Acme Nuts

The preferred method of locking a flange to a nut is a pin or set screw parallel to the screw which intersects the flange/nut mounting thread. Because of the dissimilarity of materials, the hole may need to be milled, not drilled.

Alternatively, the flange may be drilled and tapped radially for a set screw. After assembly of the flange to the nut, spot drill the nut threads through the flange and install a dog point set screw from the flange O.D. into the nut O.D. threads. Avoid getting metal chips in the nut when drilling.

Commercially available thread adhesives may be used for light load applications. Follow the manufacturers’ recommendations to ensure a satisfactory bond. Avoid getting the adhesive onto the lead screw thread.

| Diameter | Description |

| .250 to .625 | .125" × .250" Slotted Spring Pin |

| .750 to 1.000 | #10−24 × .250" Set Screw |

How does the efficiency listed for the lead screws translate to my application?

The efficiency listed in the catalog is based on a lead screw without a coating. It can be used to calculate the minimum torque required to move in the system. Torque to move is calculated in the following formula:

The torque required to move the nut in the system will help with motor or drive selection for the application.

How much life can I expect from a lead screw assembly?

For anti-backlash nuts, life is generally defined as the ability for the nut to compensate for wear. On a freewheeling nut, it is defined by the amount of wear that can be tolerated before the nut cannot hold the desired load, or the clearance that develops is objectionable for the accuracy of the system. Life can be improved by using different nut styles.

Is lubrication required on lead screws?

No. The self-lubricating polymers that we use are designed to provide adequate lubrication with no external greases. The lead screw and nut assemblies are designed to be maintenance free. If additional lubrication is needed, we offer many types of coatings. The two most popular coatings our customers use are:

- Helix H10X PTFE

- HCC1 - Ceramic Coating

Please consult the engineering at sales@helixlinear.com for more information.

Can lead screw assemblies and linear actuator products be used in a vacuum application?

This depends on your system requirements. Information is available for standard acetal materials used to indicate weight reduction over time at certain temperatures and pressures. We have the manufacturing capability to make nuts from a wide variety of materials, so it may be possible to use the materials that are known to be acceptable in your application and ensure compatibility. Please consult the engineering team at sales@helixlinear.com for more information.

Can Helix manufacture a custom lead screw nut?

Yes, we can machine and mold almost any nut shape that you require from a wide variety of nut materials. We can also 3D-print a custom nut shape for quick turnaround requirements. Email your custom nut design to sales@helixlinear.com.

What is the difference between an acme lead screw and a ball screw?

An acme lead screw uses a threaded screw design with sliding surfaces between the nut and screw.

A ball screw uses a ball nut which houses one or more circuits of recirculating steel balls which roll between the nut and screw.

What is the difference between lead screws and acme screws?

Lead screw is a generic term referring to any threaded drive screw using sliding surfaces to transmit a load.

Acme is a term that refers to a particular thread form. All acme screws are also lead screws but not all lead screws are acme screws. The acme thread standard is accompanied by specific classes such as 2G, 3G, 2C etc. which have slightly different tolerances. Acme thread forms can be easily checked using readily available thread gauges. The acme thread standard is designed for interchangeability and manufacturability.

Other kinds of Screws

Static screw applications are generally referred to as fastener screws. They utilize inefficient thread forms to prevent the nut from back driving and are not well suited for regular motion.

How is a rolled thread different from a machined or ground thread?

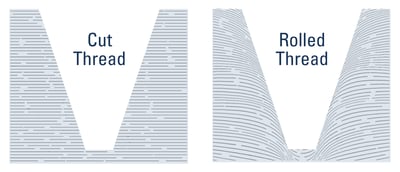

The grain structure of a rolled thread is parallel to the surface of the thread. This process results in a stronger thread in the axial direction.

A rolled thread is manufactured using a different process than the machined or ground thread. Rolling is a cold forming process, similar to forging, which moves the material to conform to a die. There is no material is removed using the rolling process. The grains of the material flow as the threads are formed. Rolled threads possess an ideal grain structure for axial shear strength, which increases the load-bearing capacity. Thread rolling "work hardens" the material in the process.

The grain structure of a machined or ground thread is parallel to the axis of the thread. Machined and ground threads are manufactured using a material removal process. This process results in a weaker thread in the axial direction.

What are the benefits of using rolled threads?

Rolled threads provide the best surface finish of all the thread manufacturing processes. They incur zero material waste, which makes it more cost effective to manufacture. They provide for continuous thread lengths of up to 12 feet or longer if needed. They also ensure high precision lead accuracies of .0003" per inch.

Rolled threads can accommodate very high lead threads, which can improve efficiency.

What is the standard operating temperature range of the assemblies?

Our standard temperature range is 32F to 200F (0 to 90C). For applications where your temperature will be higher or lower than this, other materials are available to meet your requirements, including materials that can be used in a temperature range of -450C to +145C.

What are the benefits of the H10X TFE coating?

The Helix H10X® coating

- Increases nut life by a factor of 10

- Reduces friction between the nut and screw from .15 to .09

- Increases efficiency by 10% to 20%

- Improves smoothness and can reduce or eliminate noise

What is PV?

PV is better known as Pressure Velocity. This is a key characteristic in determining the correct material for a lead screw application. The PV of an application is defined by three key characteristics:

- Applied force

- The area on which the force is applied

- Linear velocity

Knowing these three parameters we can calculate the estimated PV of the system, and if we include the duty cycle, we can get a better idea of whether the PV will be a peak number or an average number. We can decrease the PV of the system by increasing the diameter of the leadscrew, or we can change material to a higher PV threshold. If a plastic meets or exceeds its PV threshold, it will begin to flow and fill voids in the thread form, which will cause the nut to seize.

What are the standard straightness tolerances?

Although PowerAc™ acme screws are manufactured from straight, cylindrical material, internal stresses may cause the material to bend or yield.

When ordering random lengths or cut material without end machining, straightening is recommended. Handling or machining of screws can also cause the material to bend or yield. Before, during and after machining, additional straightening is required. When ordering screws with machined ends from Helix, the following straightness tolerances can be expected:

Our standard straightness for all precision lead screws up to 4 feet long is .003" per foot. We can hold a tighter tolerance, and in some cases, up to .001" per foot depending on the diameter and length.

PowerAc™ rolled acme screws are straight within 0.010 inch/ foot and will not exceed 0.030 inch in any 6-foot section, when shipped from the factory.

PowerAc™ ground acme screws are straight within 0.001 inch/foot when shipped from the factory. If tighter straightness tolerances are required, contact our engineering team at sales@helixlinear.com.

How do I determine the correct leadscrew for my application?

To choose the best lead screw your application, please send the following information to sales@helixlinear.com:

- The approximate load that the lead screw will move

- The length of travel required for your application

- The desired life of your application - hours, years, or inches of travel

- The axial speed at which the load is required to travel

- The diameter of the lead screw your application can accommodate

- The screw material required - alloy or stainless steel

What is the design load rating of the nut?

The design load rating of the nut is the axial force applied to the nut during operation. The maximum force consisting of the mass being moved, while considering the effect of acceleration and deceleration, should not be exceeded. The design load rating relates to nut life, anti-backlash, and wear compensation.

What is backdriving?

Backdriving on lead screw assemblies is the ability of a screw to be turned by a thrust load applied to the nut. Backdriving can occur when the tangent of the thread lead angle is greater than the coefficient of friction. Since this is difficult to measure, a good rule of thumb is that a screw will backdrive when the lead is greater than 1/3 the diameter on a non-lubricated screw and greater than 1/4 the diameter on a lubricated screw.

What is the difference between screw pitch and lead?

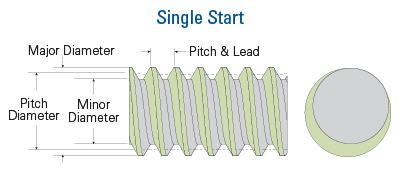

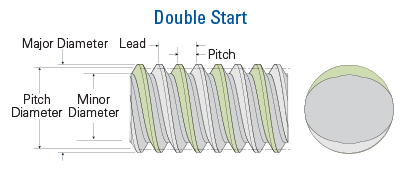

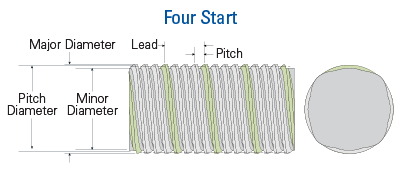

Pitch: The axial distance between threads. Pitch is equal to the lead in a single start screw.

Lead: The axial distance the nut advances in one evolution of the screw. The lead is equal to the pitch times the number of starts.

Lead = Pitch × Starts

NOTE: Helix precision lead screw designations reference nominal diameter and lead. For example: 250125 screws advance 0.125” in one revolution and require eight turns for one inch of travel. A 250125 screw has 2 starts and a 0.062” pitch.

0.062" Pitch × 2 Starts = 0.125" Lead

Do I need to grease my lead screw, and how will it affect performance?

All of our polymer lead nuts are internally lubricated, so lubrication is not necessary. However, lubrication is recommended to optimize efficiency and life. Lubrication reduces friction and wear between the nut and screw. The type of lubrication and maintenance schedule will depend upon the operating environment. Care should be taken in dirty environments to use a lubrication that will not become contaminated and form an abrasive slurry or thicken. Bronze lead screw nuts and ball screws must be lubricated to operate properly and achieve rated life.

When considering lead screws, what specifications are most important to look at?

Lead screw performance is largely a factor of axial load and rotational speed (rpm). The relationship between the two is governed by the "Pressure Velocity" or PV curve. Because lead screws operate using sliding surfaces to support the loads, heat is generated by the friction between the nut and the screw. Wear also occurs between these surfaces. The PV curve defines the safe operating limits of load and speed. As load increases, the rotational speed must be reduced to prevent excessive heating and wear from occurring. The reverse is also true. It is possible to turn the screw at high speed while applying a light load or move slowly under a heavier load. It should be noted that the travel per revolution, frequently defined as the 'lead', can be increased to increase the linear speed without increasing the required rpm. This is a good way to increase the life of a lead screw. In order to size a lead screw system, it is important to know what torque will be required to drive the load. This can be calculated simply once the efficiency if the lead screw is known. The more travel per revolution, the higher the required torque but the efficiency also increases, up to a point.

You can contact our application engineering team at sales@helixlinear.com for further assistance in selecting the appropriate lead screw or ball screw product for your application.

What are the differences between rolled and ground screws?

Rolling is preferred over cutting (turning on a lathe) for lead screws. It involves pressing a round bar between a set of dies that roll the threads into it. It results in a harder surface with superior surface finish for lead screws. Rolling is also the most common process for ball screws because it is more economical and sufficiently accurate for most industrial applications. Lead accuracy can be held to better than .003 inch/foot and longer lengths are possible than with ground screws.

Rolling is preferred over cutting (turning on a lathe) for lead screws. It involves pressing a round bar between a set of dies that roll the threads into it. It results in a harder surface with superior surface finish for lead screws. Rolling is also the most common process for ball screws because it is more economical and sufficiently accurate for most industrial applications. Lead accuracy can be held to better than .003 inch/foot and longer lengths are possible than with ground screws.

If higher accuracy is required, grinding should be considered. The grinding process can hold lead accuracy’s as tight as .0003 inch/foot or better. However, this process is much more expensive and the maximum length of screw is much shorter.

The images show the difference in grain structure for rolled and ground threads.

Can you explain screw starts?

Screw starts are the number of independent threads on the screw shaft. See illustrations below:

Suggested Reading

Not sure what you need? Unlock the full potential of your mechanical systems with our step-by-step guide on selecting the perfect lead screw!

Tap into our linear motion expertise. Click to learn how the smooth, reliable movement of our precision lead screw and ball screw assemblies, and linear actuators can optimize your application success. Learn more on our Blog

Speak to an Application Engineer

Our application engineers are here to help you plan, customize and select the optimal linear motion components for your additive manufacturing application.