Acme Screws

High-Performance for Precision Linear Motion

Engineered for strength, reliability, and repeatability — Helix Linear’s Acme lead screws deliver smooth motion and long service life in demanding industrial and custom applications.

🔹 Browse Acme Screws

🔹 Request a Quote

🔹 Download Technical Catalog

At Helix Linear, we pride ourselves on providing our customers with the best service possible. We are becoming the benchmark in the industry, and our support goes beyond design and manufacturing. Our value-added services complement our core expertise, making us the world’s leading solution provider in rolling and linear technology.

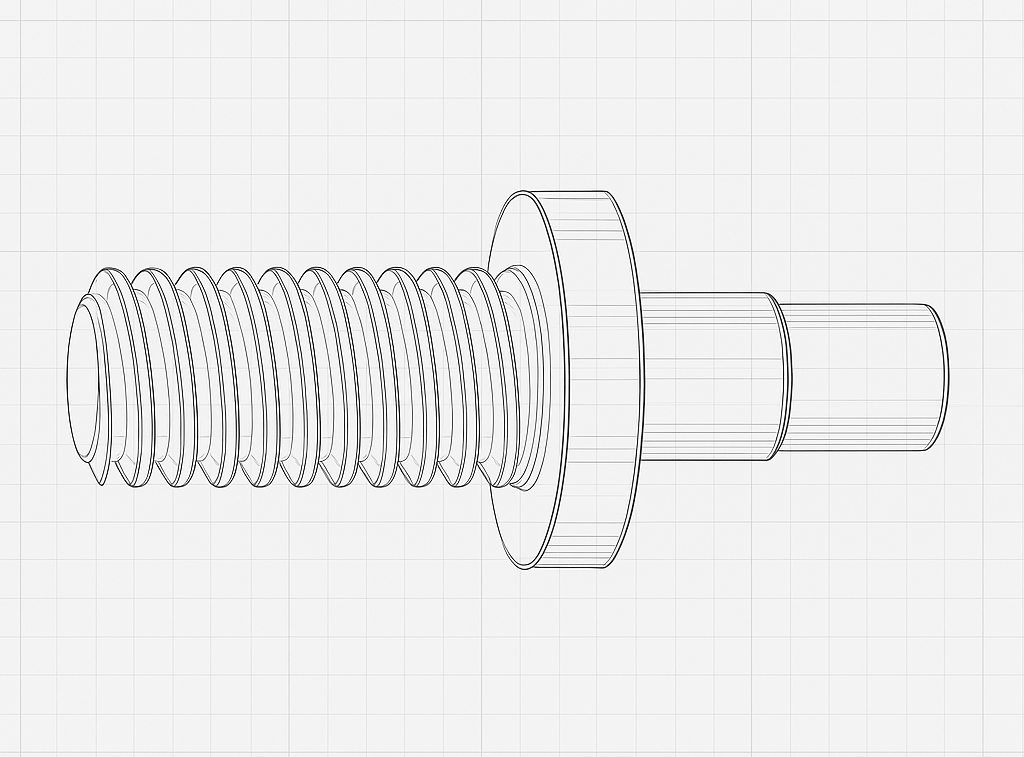

What Is an Acme Screw?

Acme screws are trapezoidal-threaded power transmission screws designed to convert rotary motion into linear motion with high load-carrying capacity and low backlash. Unlike ball screws, Acme screws are self-locking in many cases and require minimal maintenance, making them ideal for static load and vertical applications.

At Helix Linear Technologies, we specialize in both standard and custom Acme screw solutions — optimized for smooth performance, durability, and precision across a wide range of motion control needs.

Standard & Custom Acme Lead Screw Options

Explore our full selection of Acme lead screws available in multiple diameters, thread forms, and materials — or work with our engineers to create a solution built for your specs.

-

Single Lead Acme Screws – For efficient linear motion and high strength

-

Multiple Start Acme Screws – Increase speed and efficiency in limited spaces

-

Precision Machined Ends – Ready-to-install configurations

-

Stainless Steel & Coated Options – For corrosion-resistant and cleanroom use

Custom Acme Screws Designed Around Your Application

Helix Linear is known for our rapid prototyping and tailored engineering services. We can customize your Acme screw in the following ways:

-

Lead, pitch, and thread form

-

Screw length and diameter

-

Machined ends to fit your assembly

-

Material selection (stainless steel, carbon steel, plastics)

-

PTFE coating, hard anodizing, or specialty treatments

Whether you’re working in aerospace, automation, medical, or defense — we can build a screw to match your exact specs.

Engineered for Tough Applications

Helix Acme screws are trusted by engineers and OEMs across industries where precision and strength are non-negotiable.

-

Aerospace actuators & payload deployment

-

Industrial automation & heavy-duty positioning

-

Robotics & end-effector movement

-

Medical devices & diagnostics

-

Military-grade mechanisms

The Helix Linear Advantage

We don’t just deliver motion components — we deliver peace of mind. Here’s what sets our Acme screw solutions apart:

-

Made in the USA with ISO-certified processes

-

Short lead times and fast shipping

-

Real engineering support and design consultations

-

Customization at scale — no minimums

-

High-quality materials and precision machining

-

Design tools, CAD files, and technical resources

Suggested Reading

Not sure what you need? Unlock the full potential of your mechanical systems with our step-by-step guide on selecting the perfect lead screw!

Tap into our linear motion expertise. Click to learn how the smooth, reliable movement of our precision lead screw and ball screw assemblies, and linear actuators can optimize your application success. Learn more on our Blog

Speak to an Application Engineer

Our application engineers are here to help you plan, customize and select the optimal linear motion components for your additive manufacturing application.