Our new Director of Sales and Marketing, James Brooks, brings decades of global experience and a deep understanding of motion control technology to the team.

Blog

As CEO & Owner, Chris Nook has guided Helix through innovation, and expansion to shape the company into a partner for the world’s most demanding industries

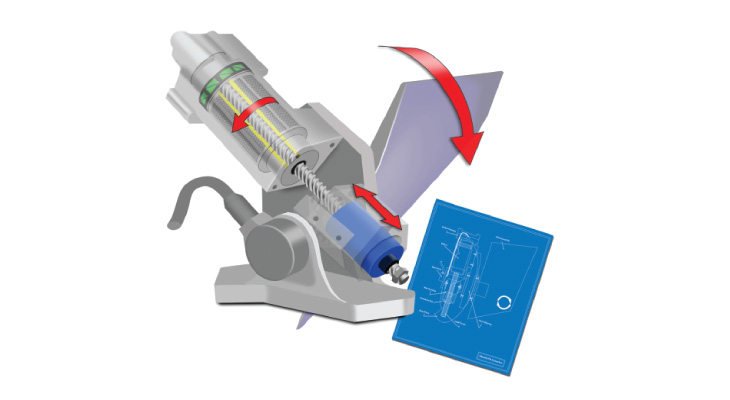

One of the most exciting shifts we’re seeing in mobility, automation, and aerospace today is the rise of the electro-mechanical brake actuator (EMBA).

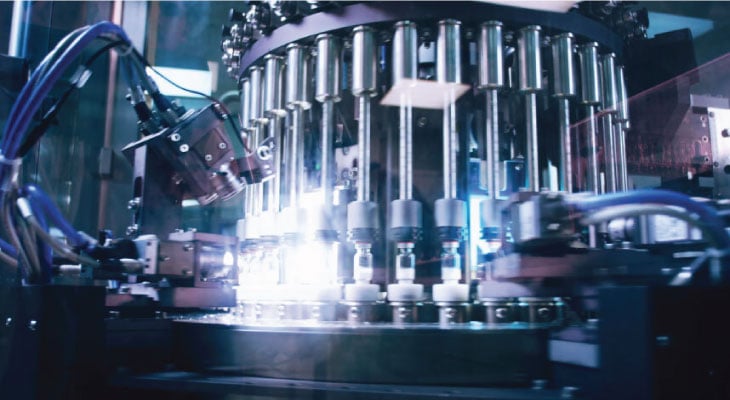

At Helix Linear Technologies, we bring decades of expertise to the table, providing motion control solutions that address the unique challenges of the healthcare field.

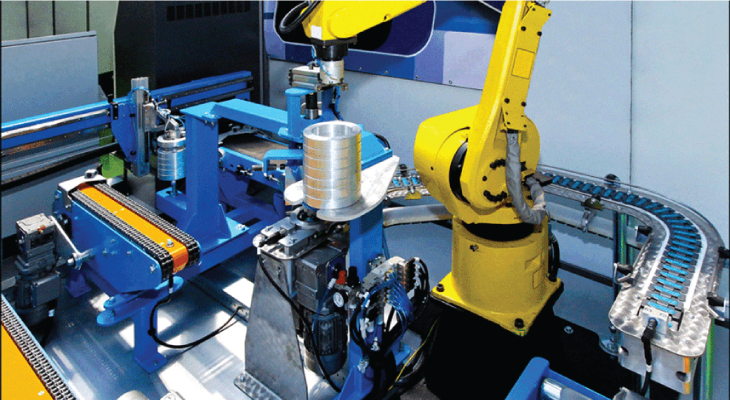

To build a robotic arm that performs with precision, stability, and durability, choosing the right components is critical.

Companies in robotics, automation, and mobile design seek precise, efficient, and durable motion control components to enhance performance and reliability.

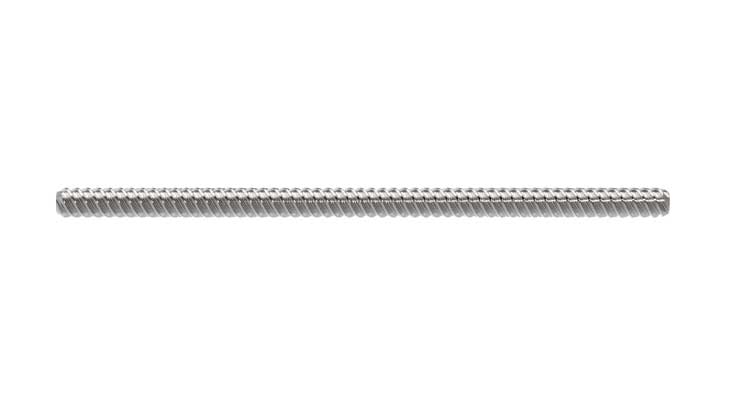

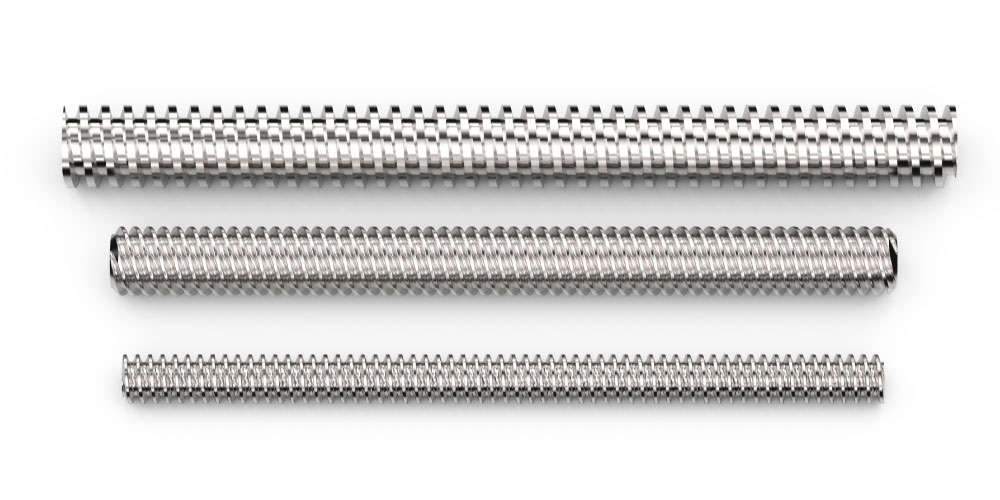

Unlike standard lead screws, High-helix specialized screws feature a steeper helix angle, allowing for greater lead per revolution.

Helix Linear Technologies is pleased and excited to announce that David R. Arguin has earned the promotion to President and member of our executive team.

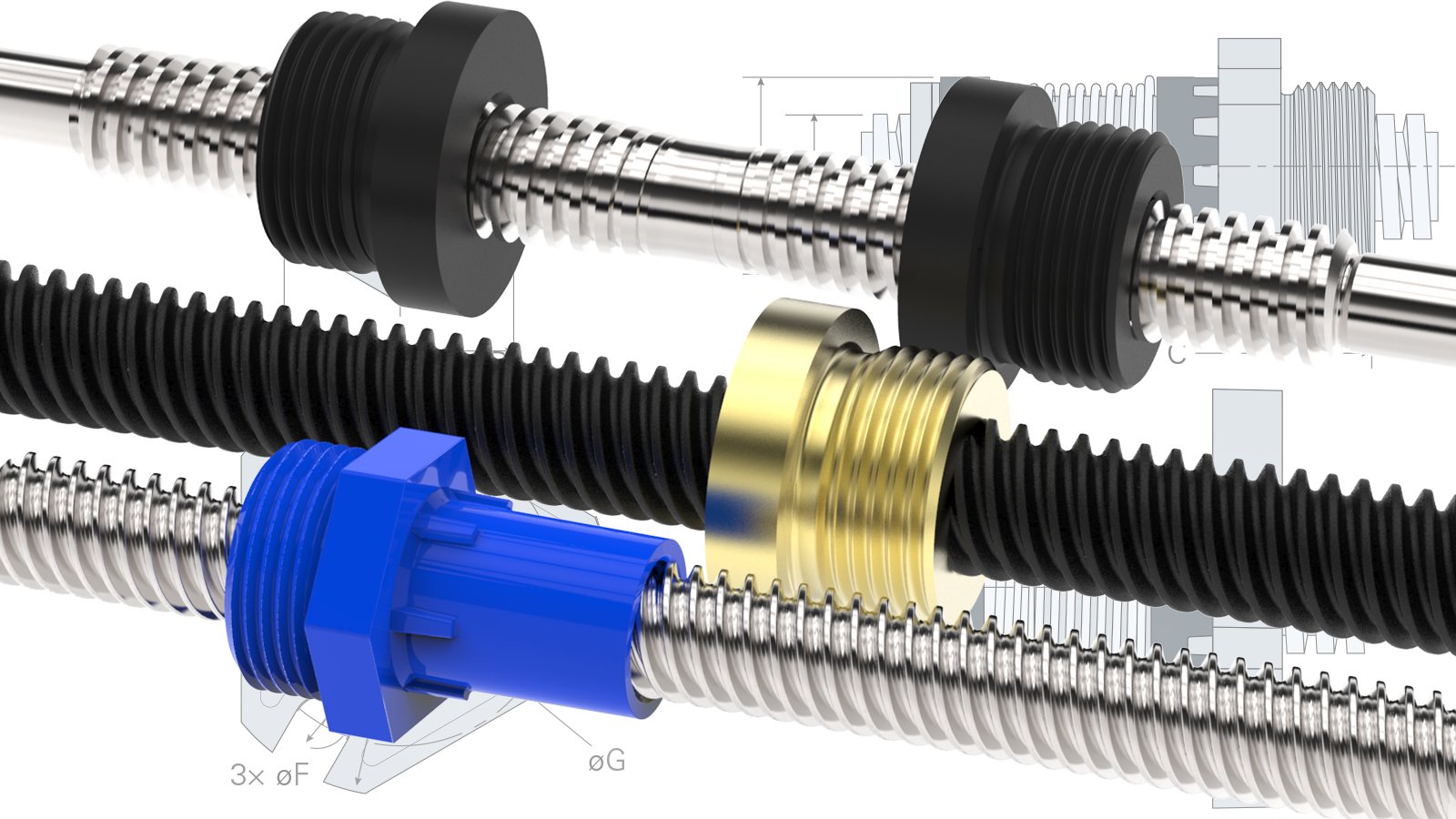

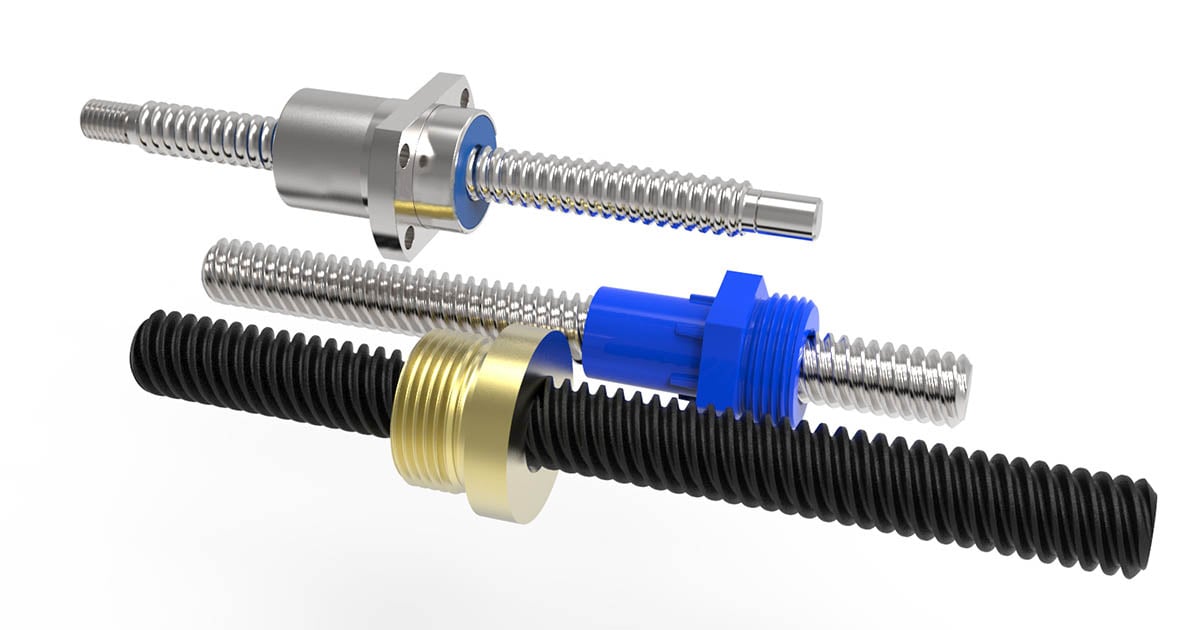

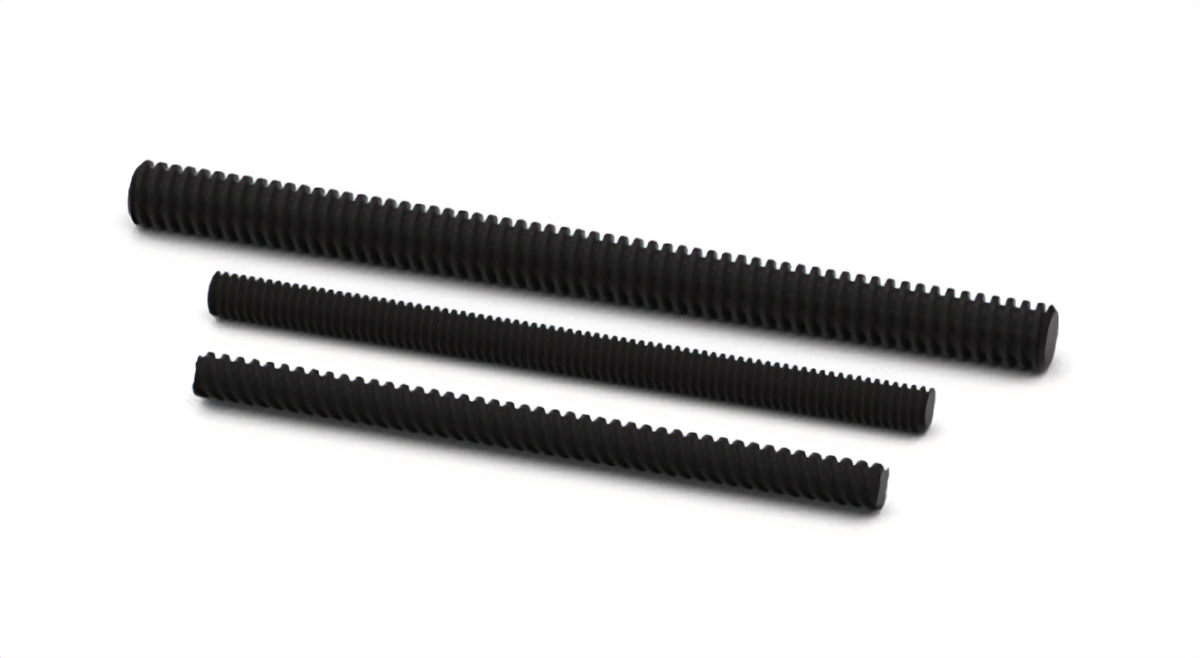

Helix's Acme screws offer high load capacity, durability, and precise motion, making them ideal for heavy-duty applications in demanding environments.

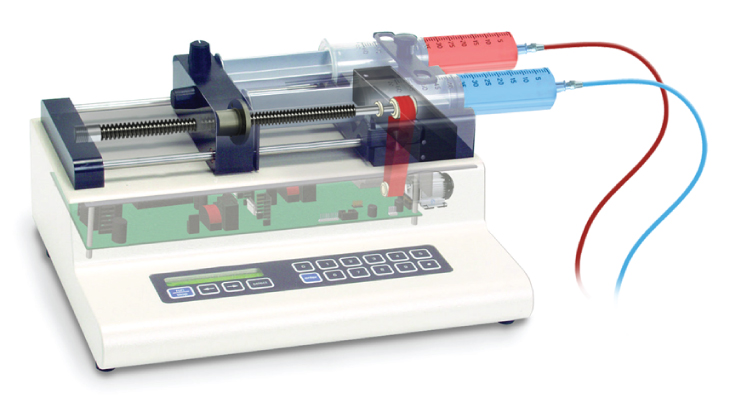

Learn about how Helix Linear's ball screws are used for medical device applications, focusing on their manufacturing processes, precision and suitability.

Learn factors affecting load capacity in linear motion systems, including materials, bearing design, and screw geometry, with tailored solutions from Helix

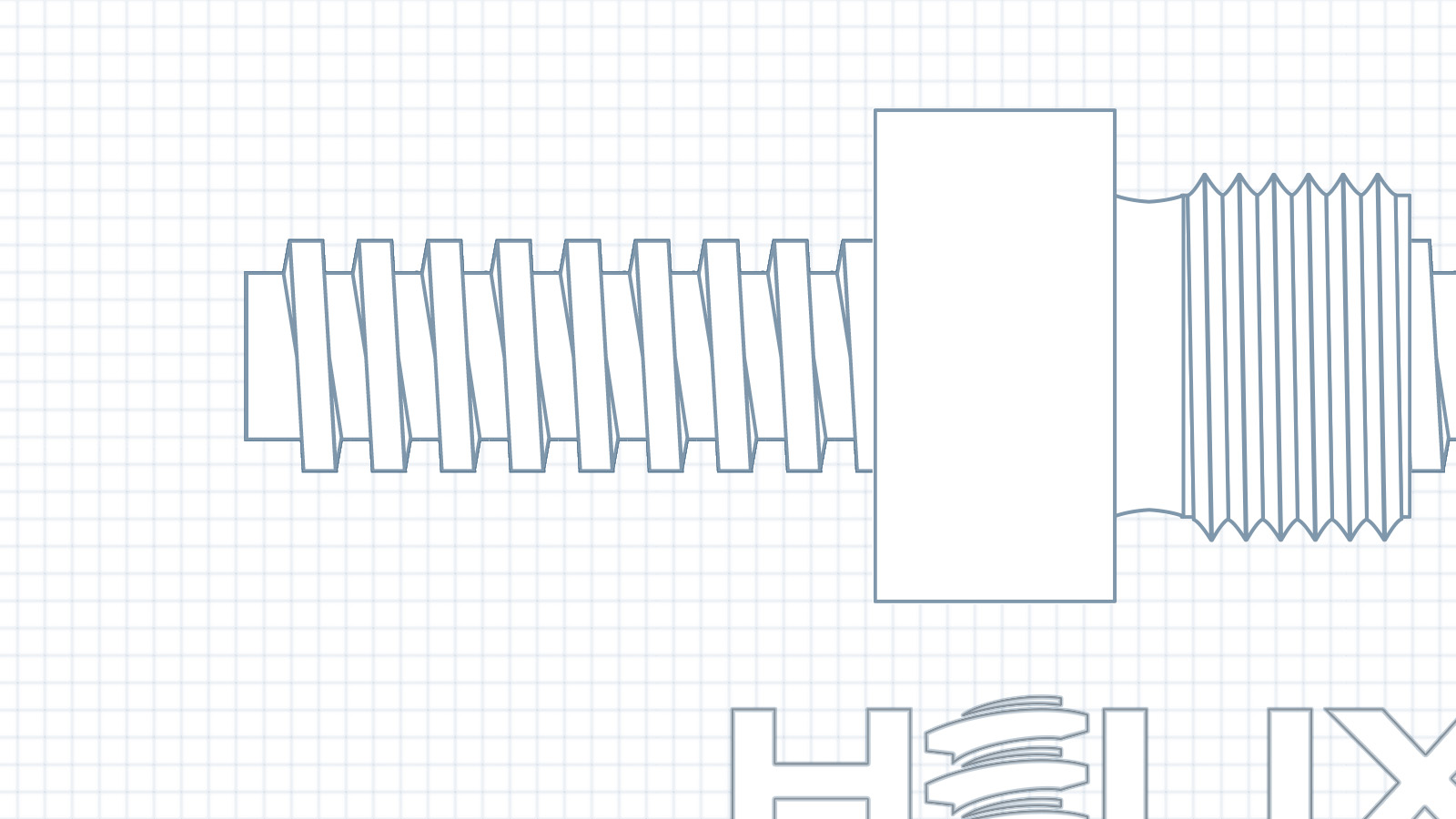

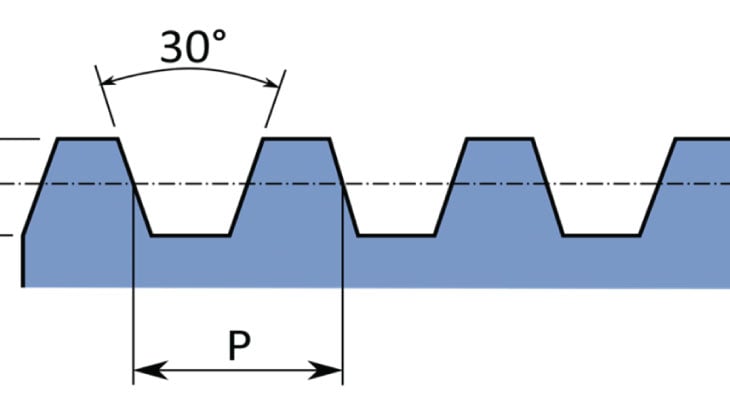

Discover how thread pitch influences lead screw performance, affecting speed, load capacity, precision and efficiency. Learn how to select the right pitch.

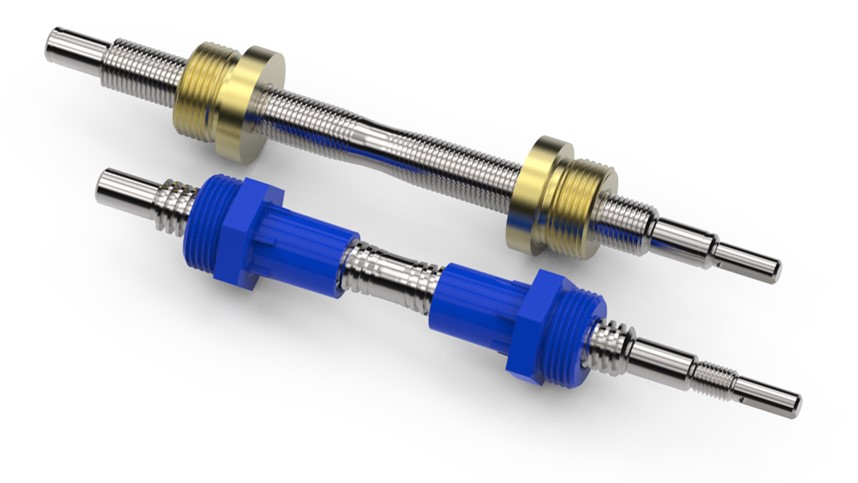

Explore the differences between Helix's rolled and ground ball screws, including manufacturing, accuracy, cost and suitability, to choose your project.

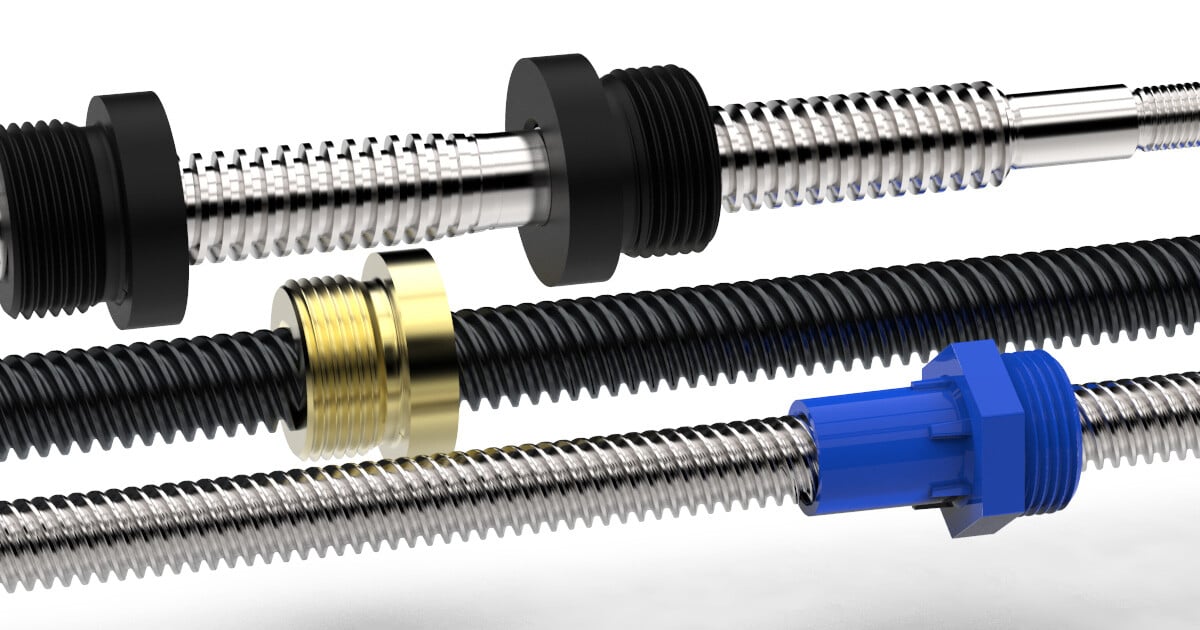

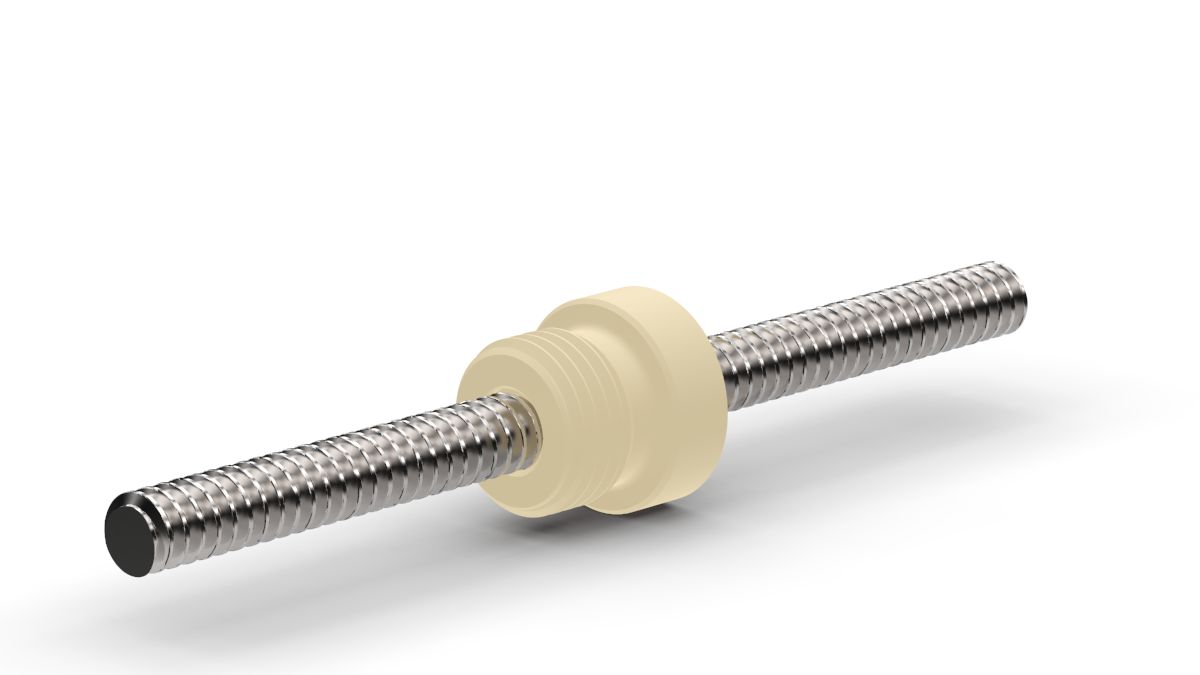

Understanding distinctions between ball screws and lead screws is important for optimizing your systems, whether aiming for precision or durability.

While lead screws often operate efficiently with minimal maintenance, here's a comprehensive guide on when and how to lubricate your lead screws.

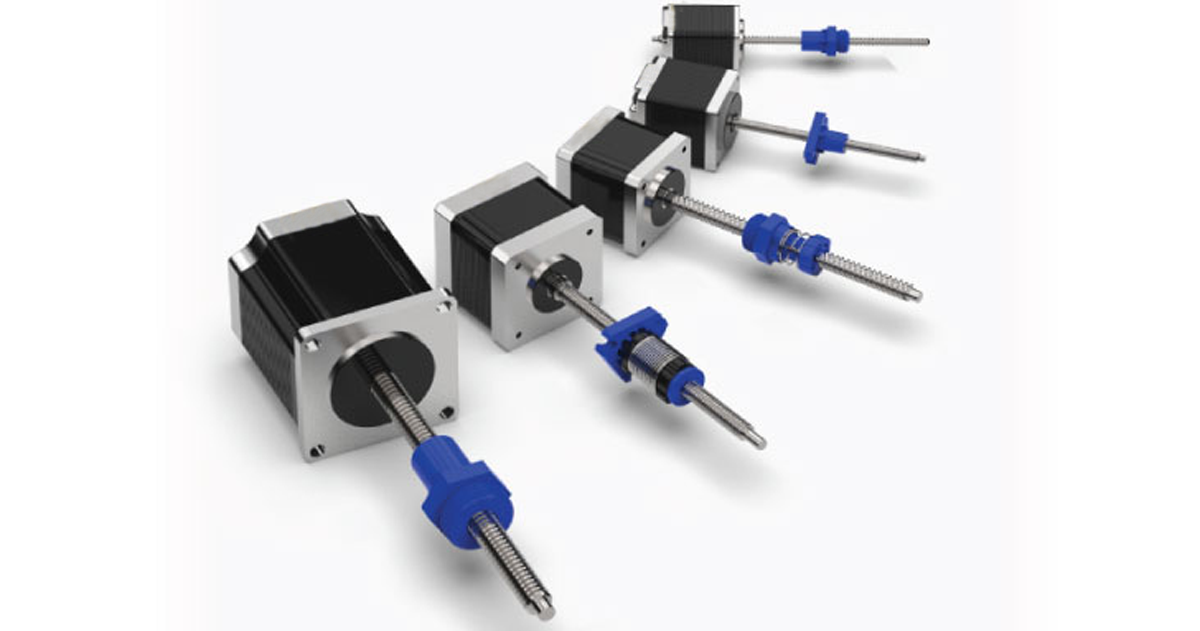

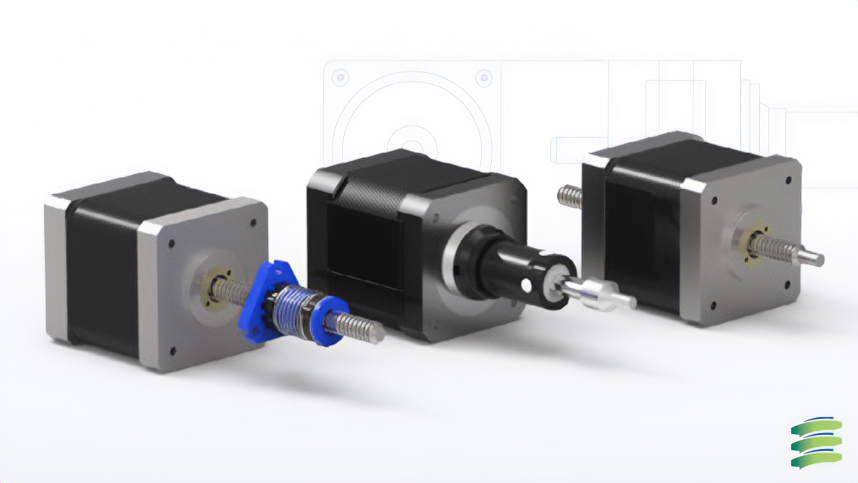

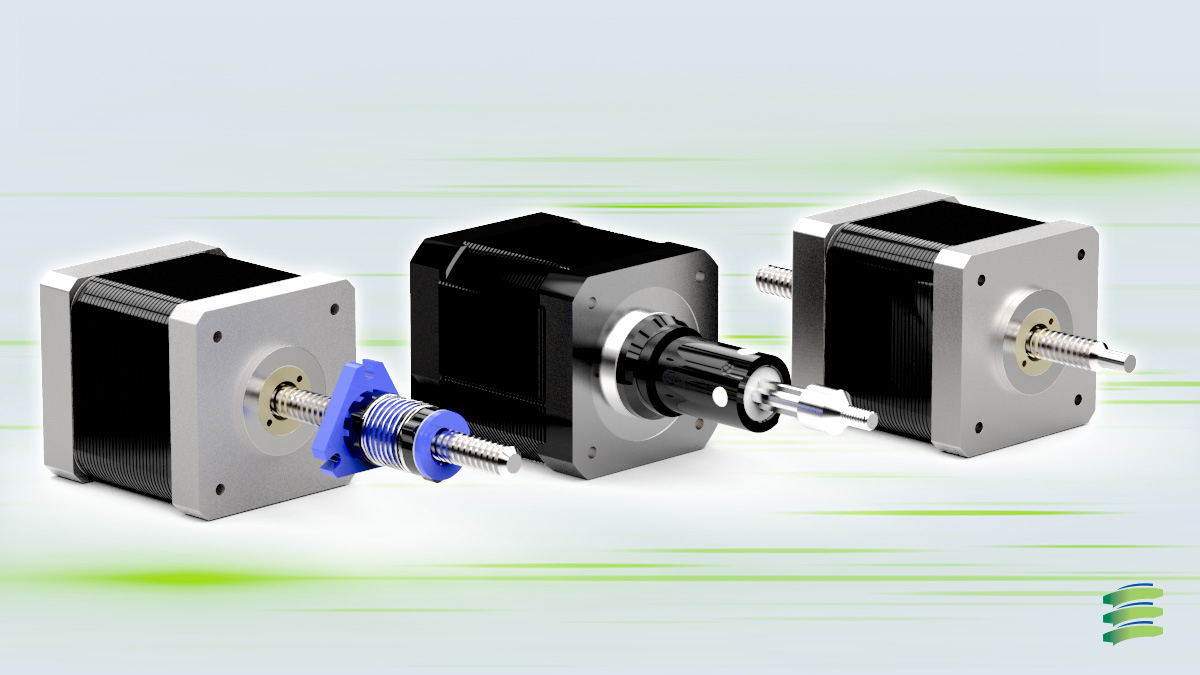

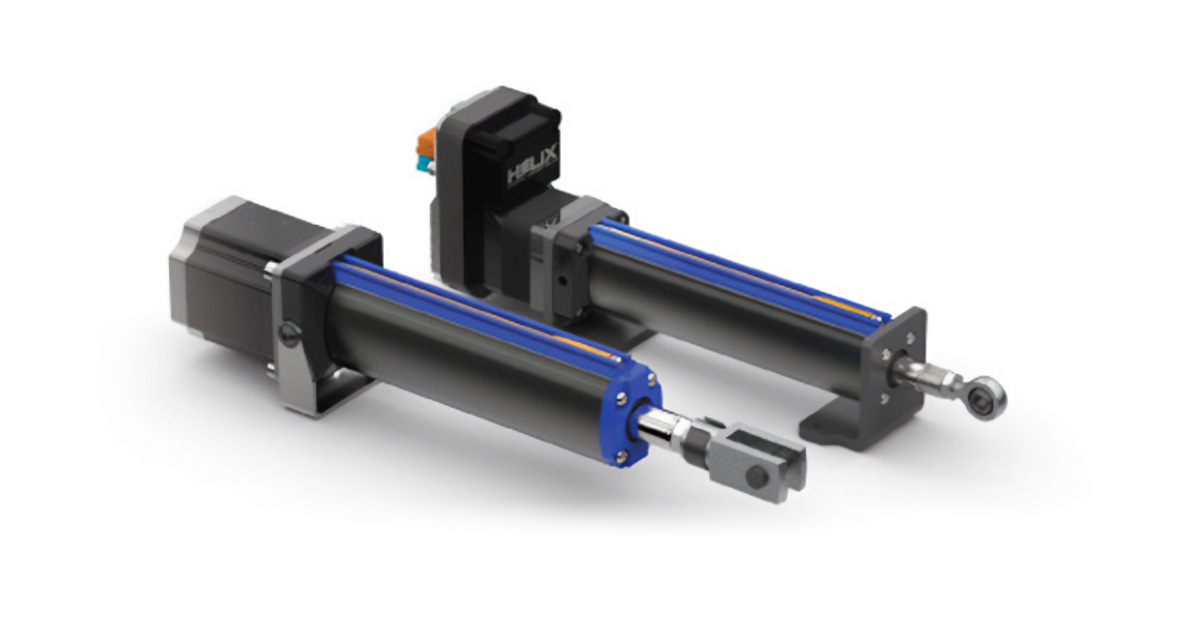

Stepper motor actuators are electromechanical devices that transform electrical energy into accurate and precise mechanical movement and they use linear motion.

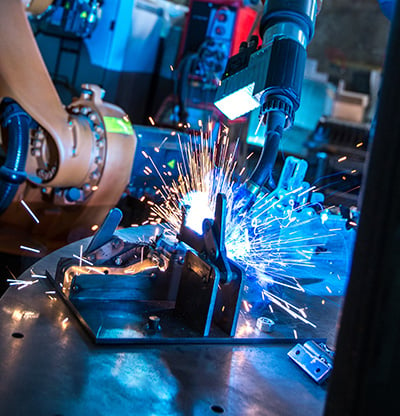

Advancements in manufacturing processes and materials have revolutionized the linear technology industry, driving efficiency, precision and quality improvements.

Discover how distributors can use linear motion technology to enhance efficiency! Explore market trends, key growth drivers and opportunities to stay ahead

How linear motion promotes sustainability and eco-friendly choices by enhancing efficiency, reducing power consumption and maximizing equipment longevity!

Choosing the right ball screw for you application is a crucial step that can impact many factors throughout your linear motion project systems.

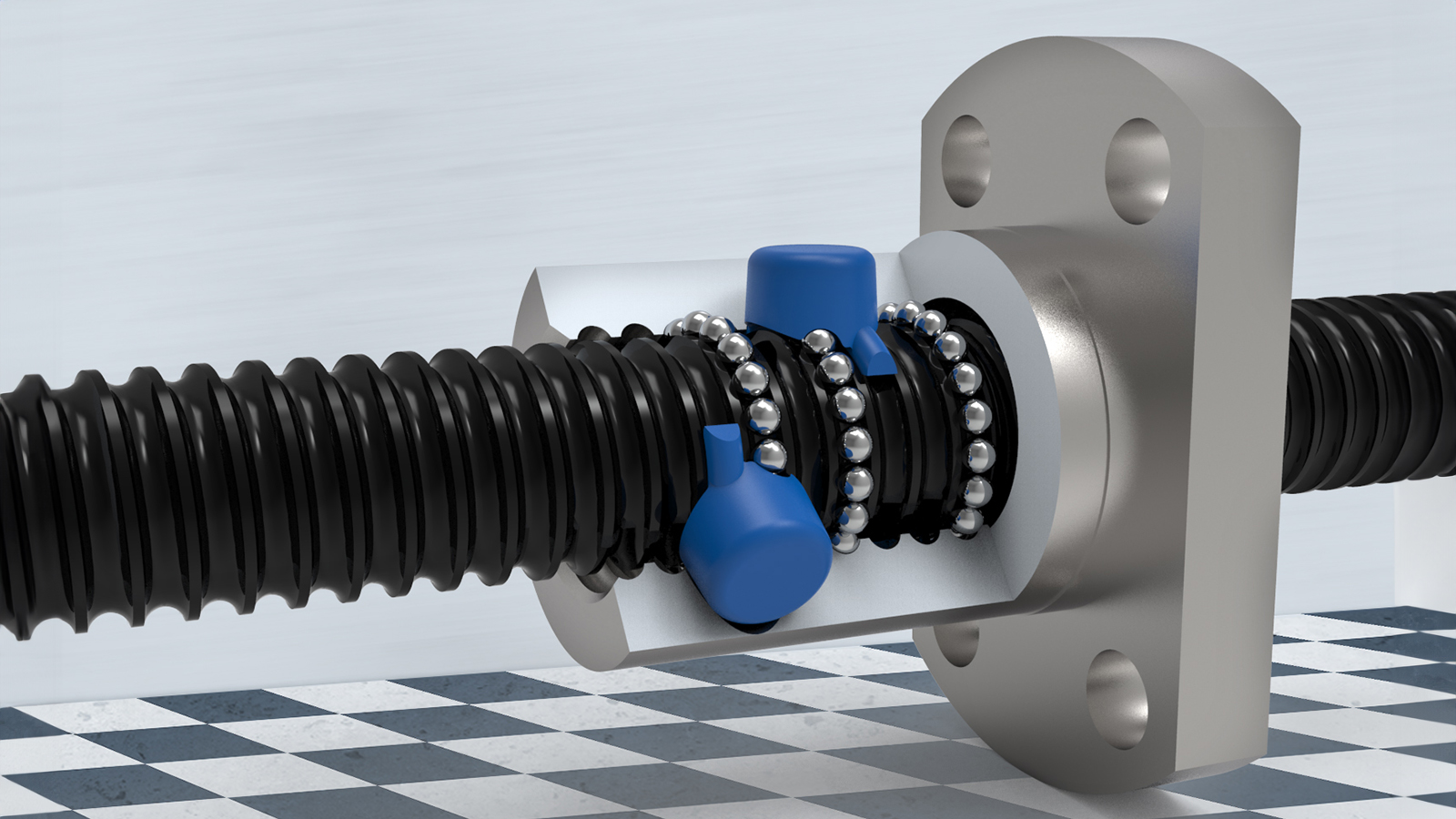

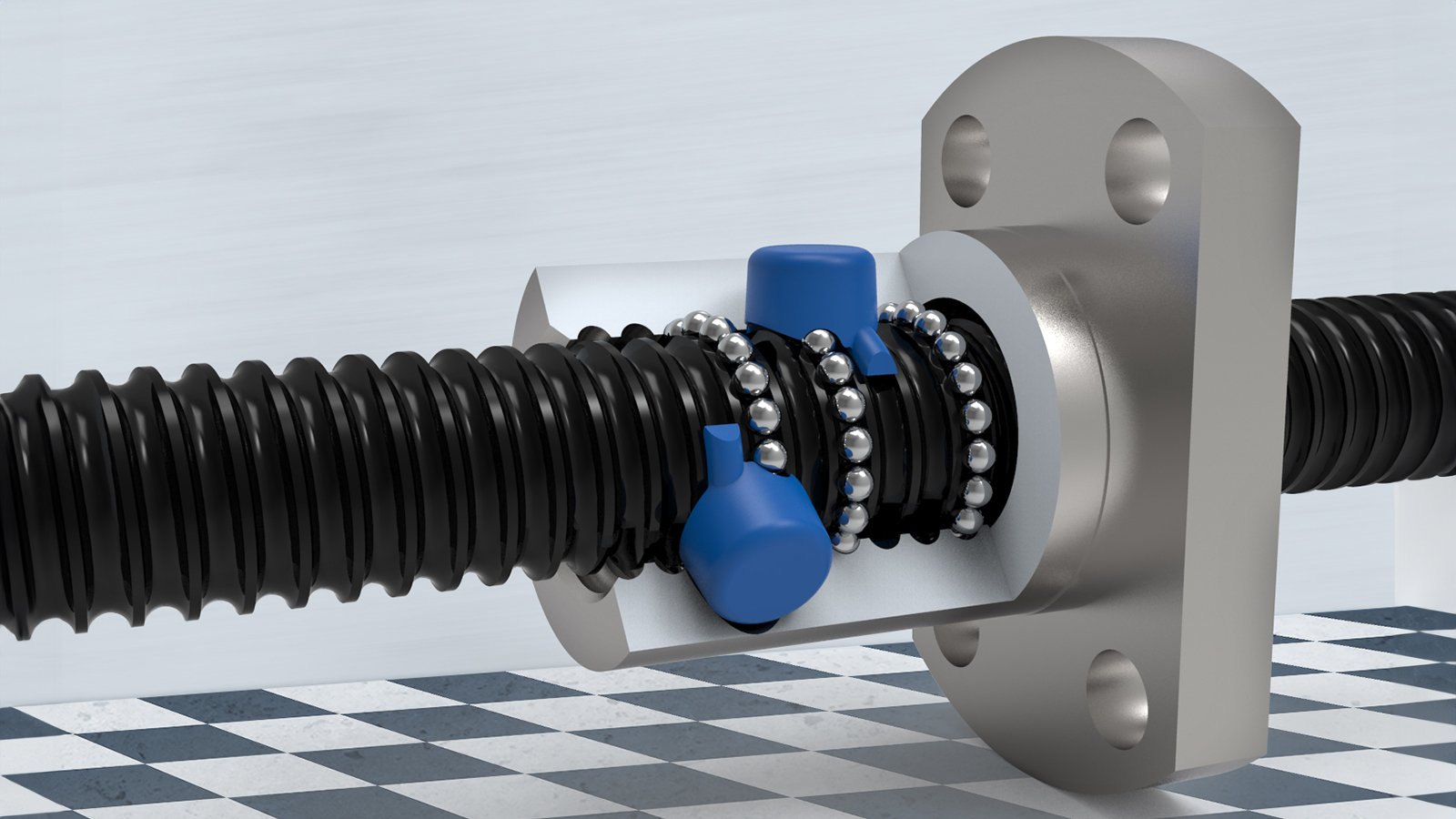

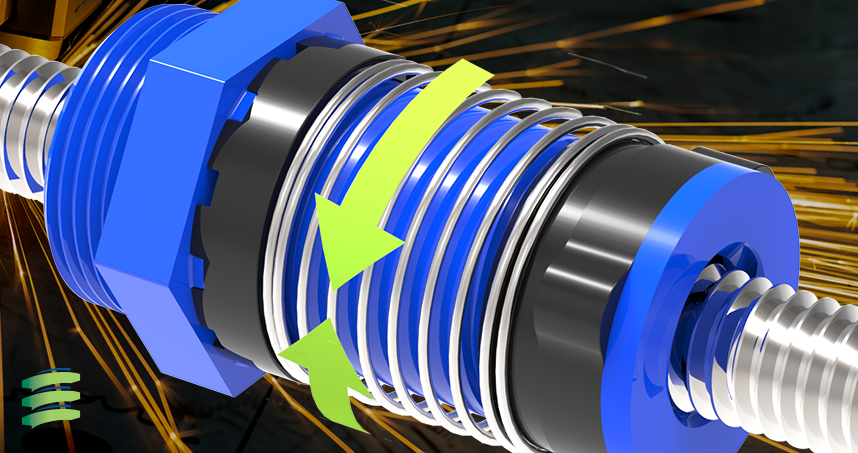

Having a full understanding of what a ball screw actually is and how it works can benefit your linear motion applications in the long and short run.

With the proper lubricant and precise maintenance, it continues to become easier to ensure that your ball screws operate with increased longevity.

Precision Motion Systems requires a lot of important pieces to stay efficient. Ball screws are one of the essential pieces that ensure smooth applications.

In linear motion systems, acme lead screws can be hard to understand. However, by learning the different misconceptions, you can be more prepared.

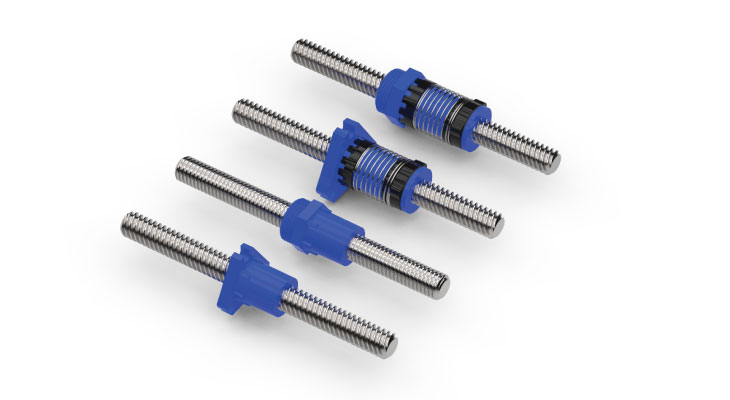

Lead screws play an essential role in linear motion systems by ensuring and optimizing the efficiency and repeatability of various applications.

In this post, we will explore the four critical design elements of lead screws that must be properly addressed to achieve success in your applications.

Selecting a precision linear motion partner and including them in the design phase can help lower project costs, enhance functionality and many more.

Explore five critical and effective questions that must be answered to achieve success and precision when using trapezoidal screws for your application.

In this blog post, find out 3 lead screw examples where these tools are used and how they work in each type of medical imaging application.

Through facing unprecedented challenges, the medical field utilizes new automatic hospital bed designs that can benefit from linear actuator systems.

Helix Linear Technologies offers a variety of effective and enhanced engineering calculators that will help you compute your linear technology needs.

Don't know which screw to use for your applications? Well, here are the pros and cons of using either an acme lead screw or ball screw for your project.

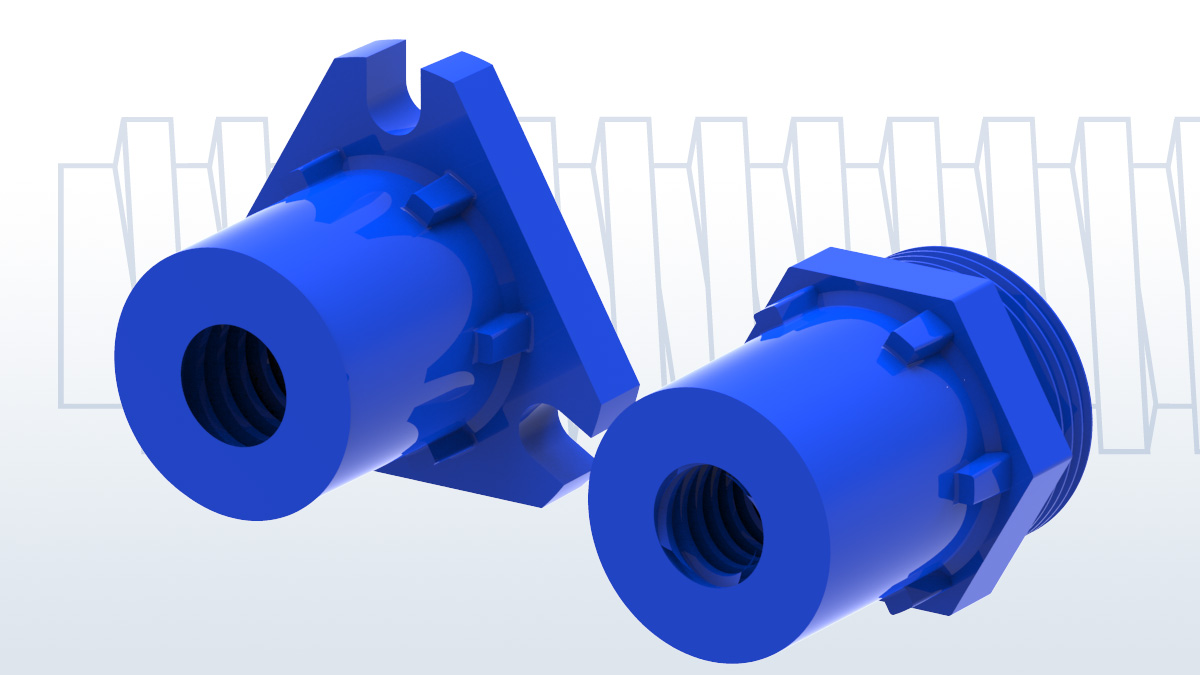

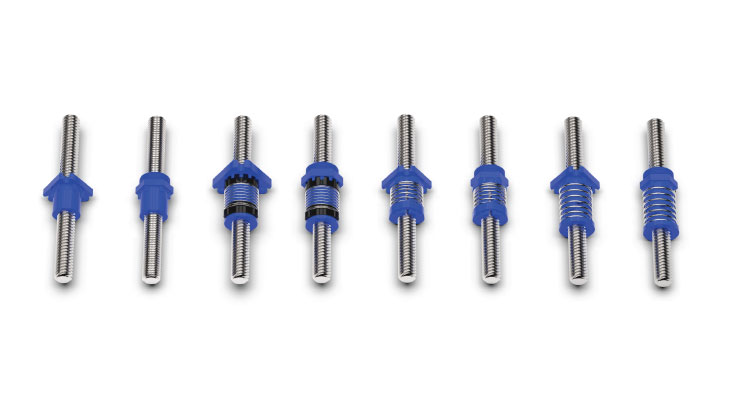

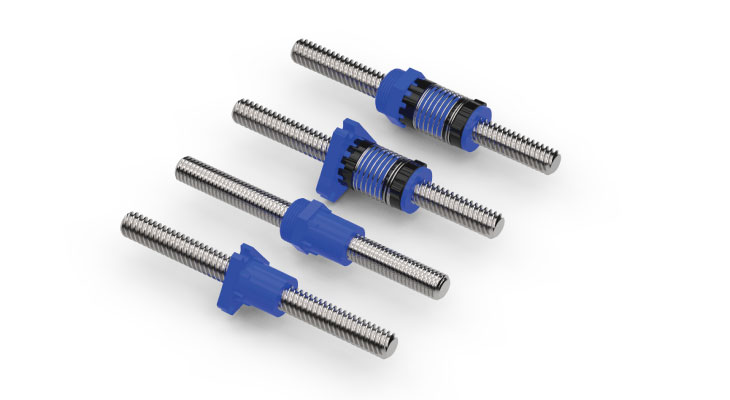

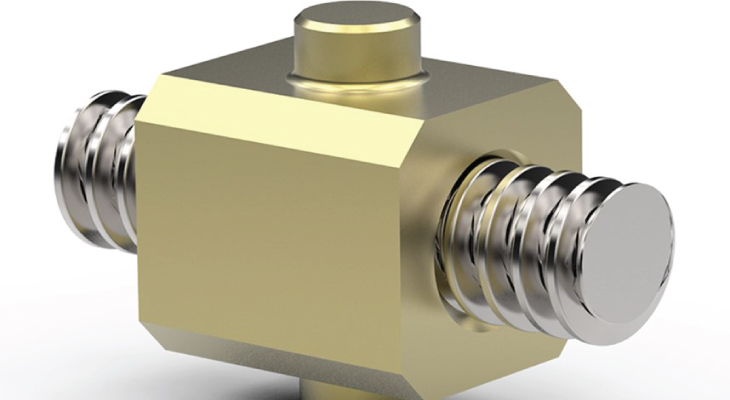

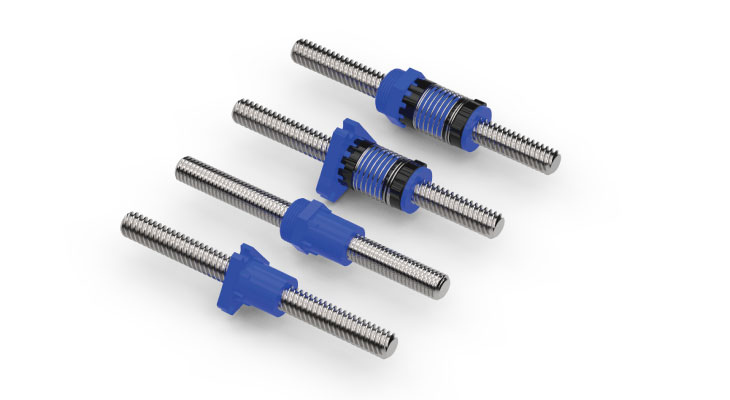

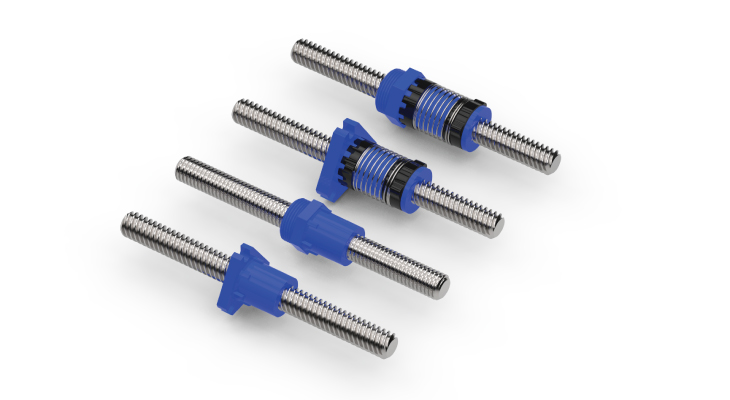

Some of the unique design variables that you might want to consider during the nut-selection process. Custom lead screw nuts can help with your application

Linear motion suppliers benefit medical industry by cutting down costs and helping everything run faster. Helix Linear Technologies provides great products.

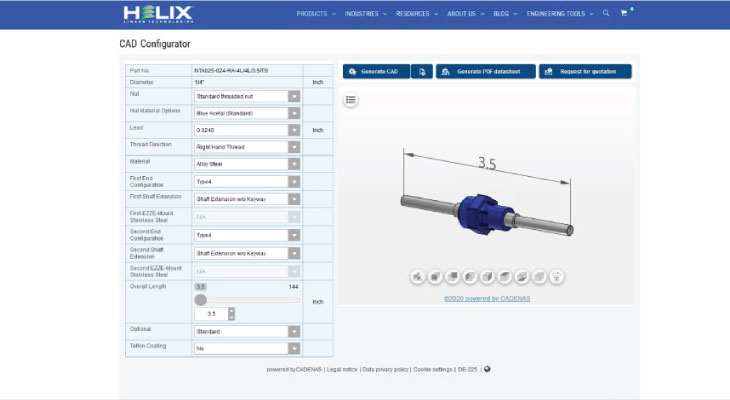

Build a custom lead screw or linear actuator CAD file in just a few quick clicks with the new partnership between Helix Linear and CADENAS PARTsolutions!

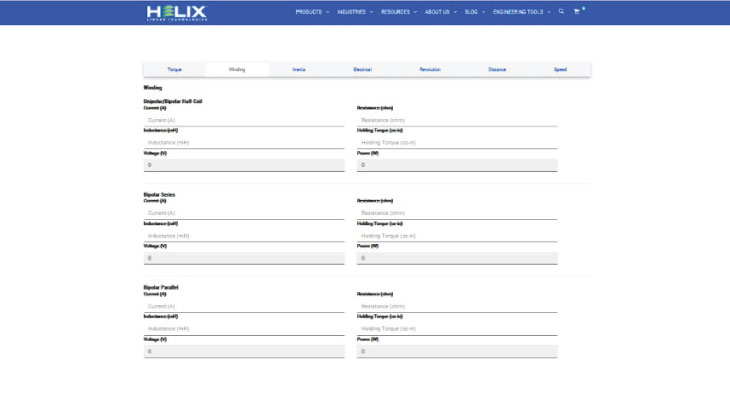

With Helix Linear Technologies' new stepper motor calculators, you’ll now be able to calculate torque and much more to better enhance your applications!

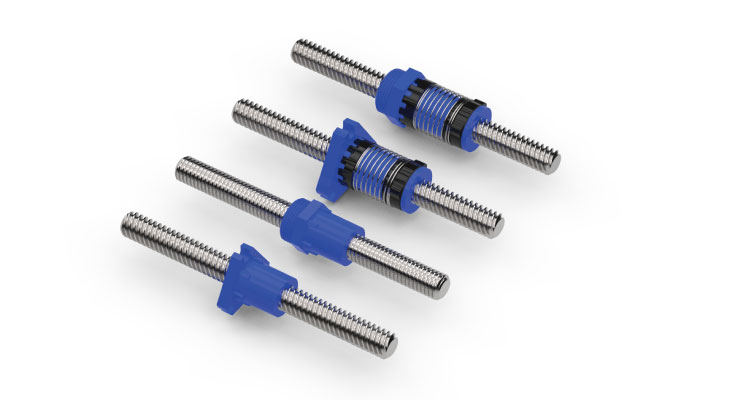

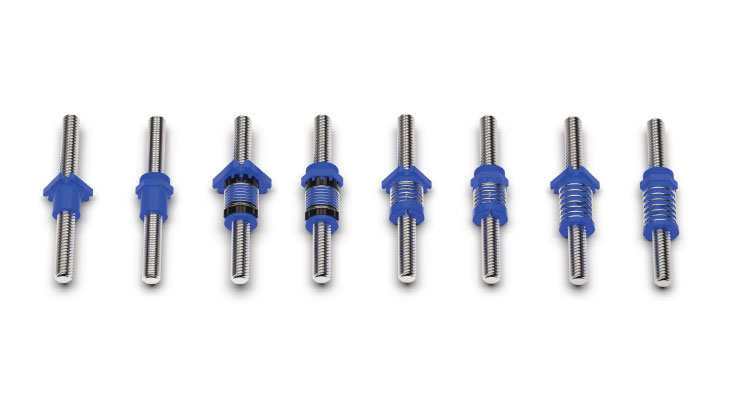

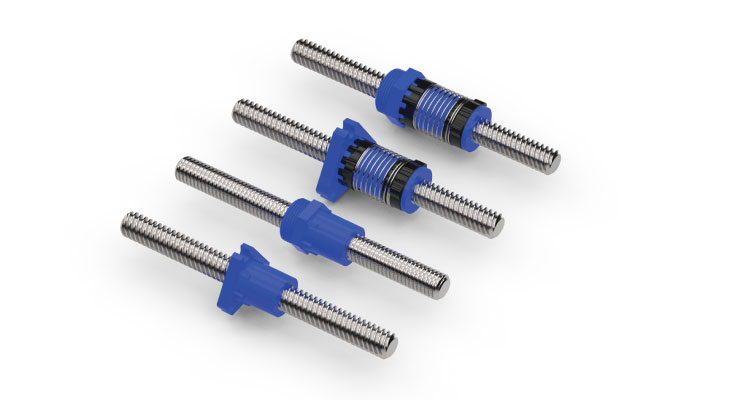

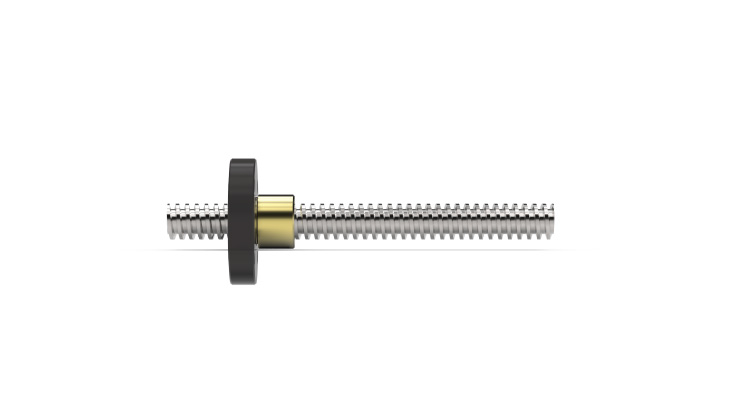

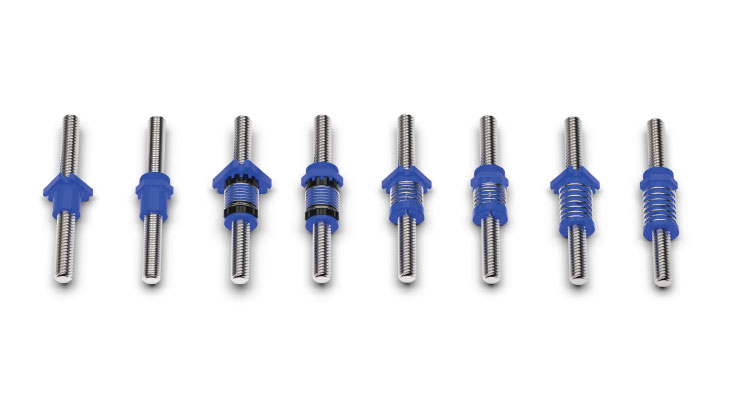

Standard freewheeling lead screw nuts from Helix Linear Technologies are available in both threaded and flanged configurations so you can benefit too!

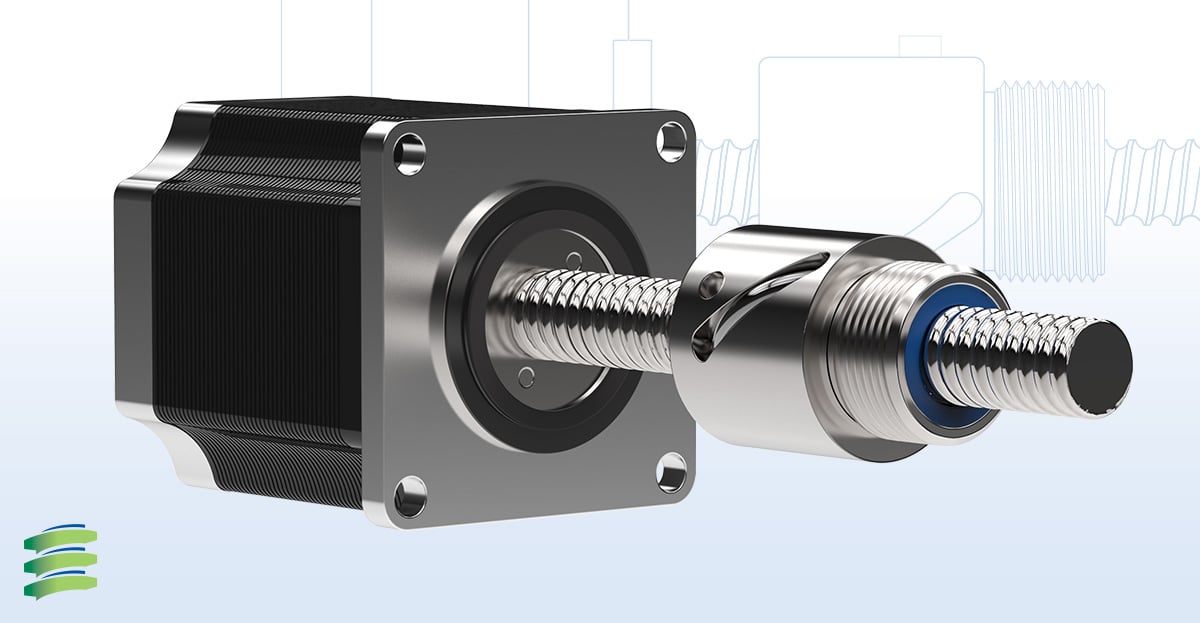

With a captive and non-captive linear actuator, the lead screw is prevented from rotating to translate rotary motion into linear motion, offering precision.

Here's an in-depth look at the top five benefits of using an electric linear actuator and why more engineers are trending toward this type of technology.

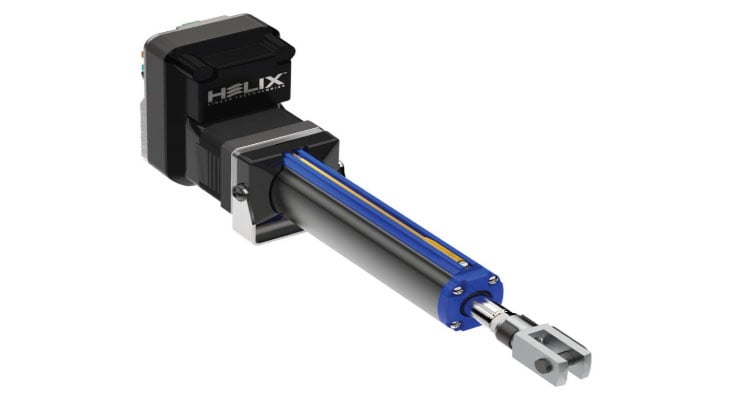

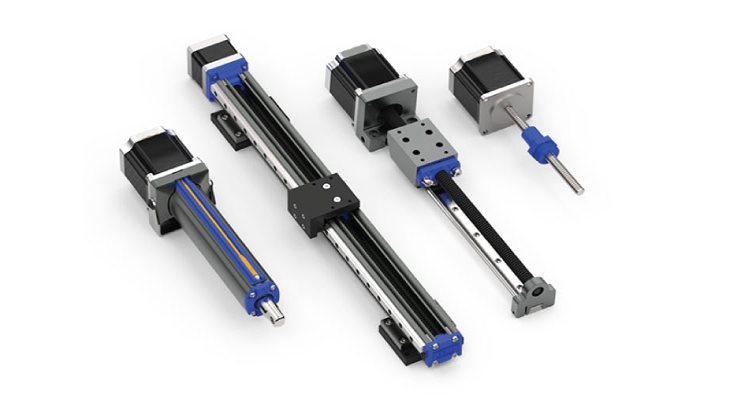

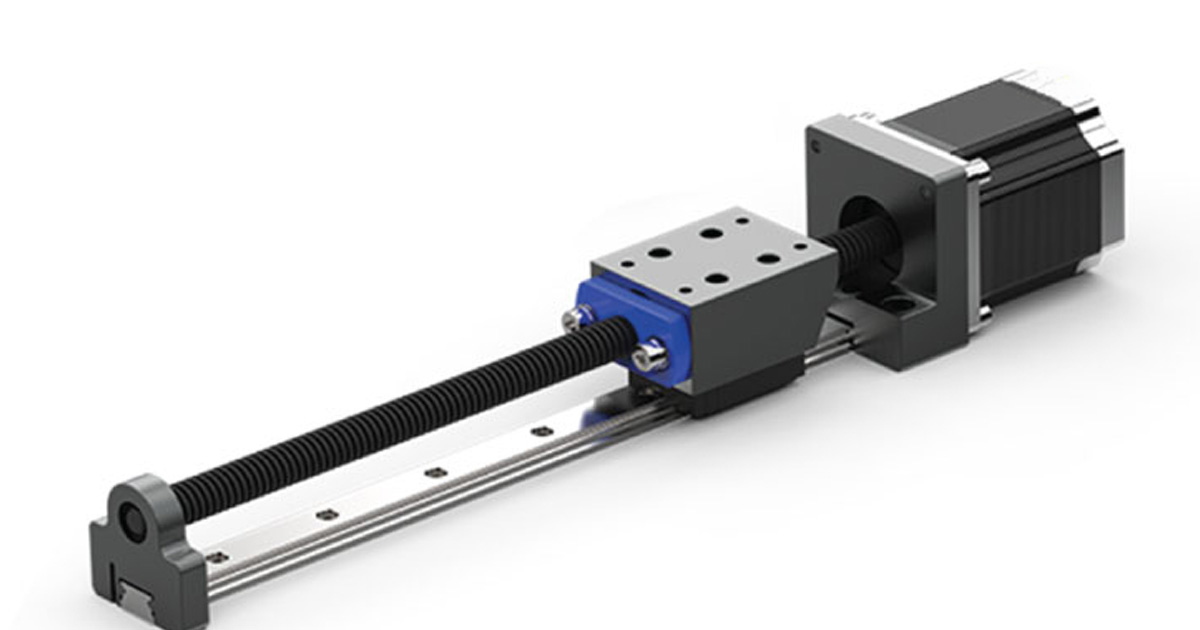

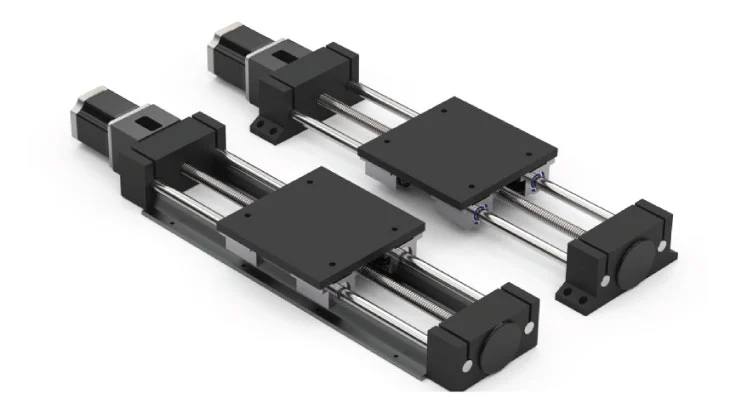

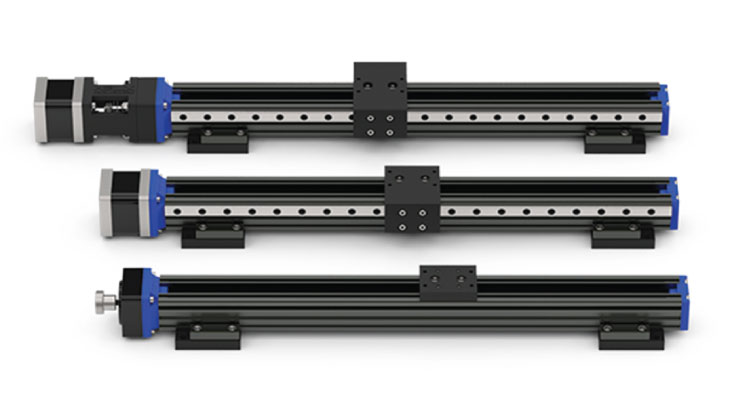

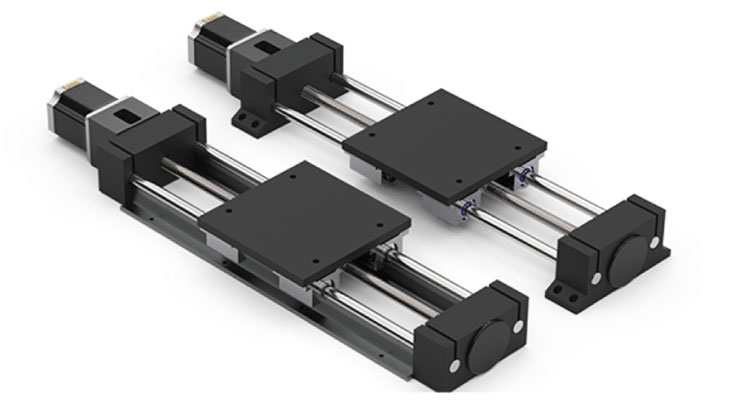

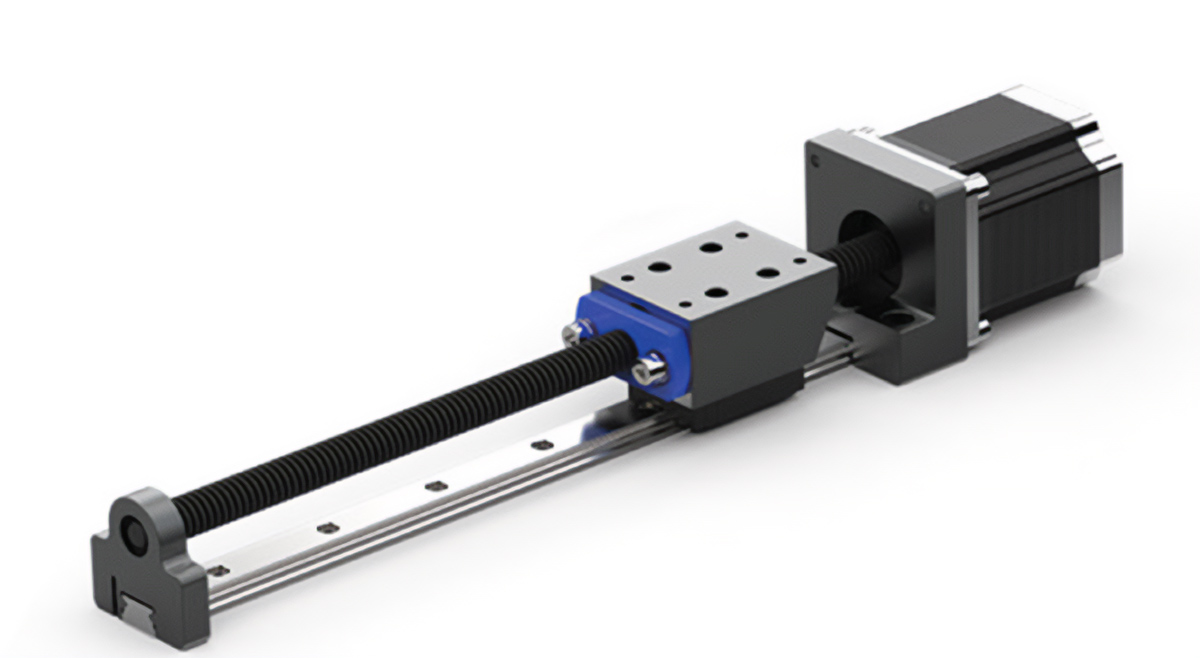

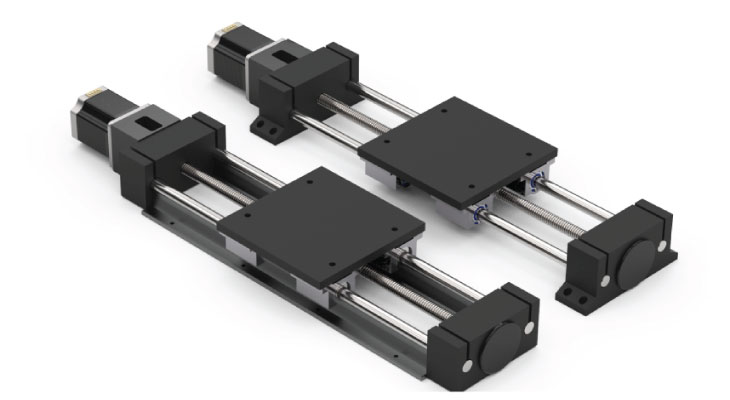

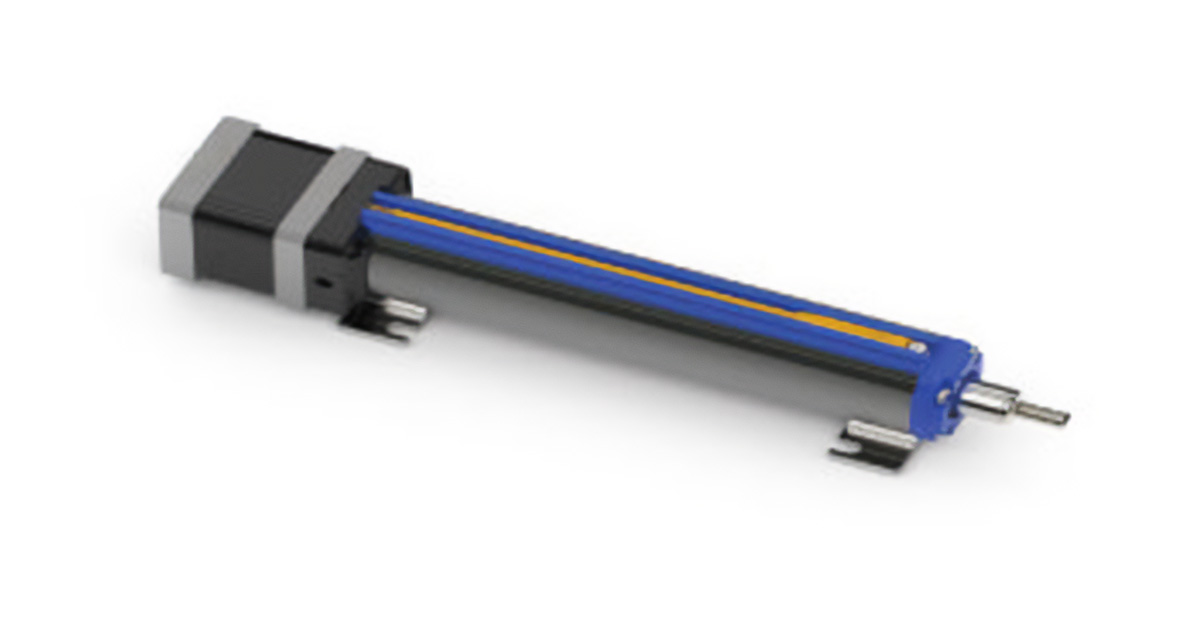

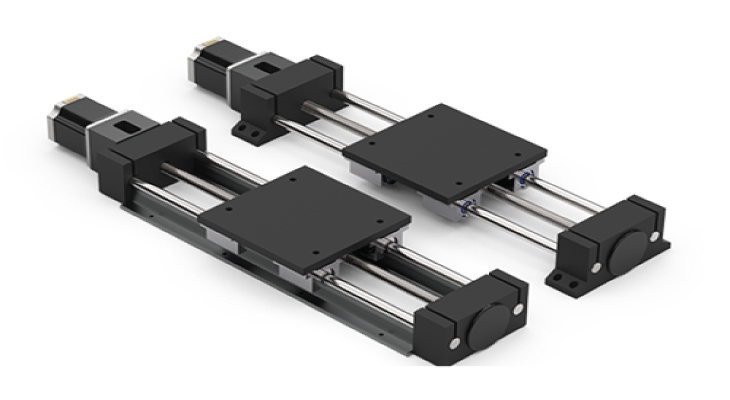

Profile Rail Linear Actuators from Helix Linear Technologies combine all the aspects of a precise linear motion system to have great impact on applications.

We have all been there—you saw a great idea and thought, “I can do that.” This blog post will discuss how you can make your own linear actuator effectively

Today's linear motion and automation challenges require higher precision and faster speeds. Through different advancements, linear actuators are effective!

Linear Guide Systems are the most diverse group of products in the motion control industry. Learn the effective ways of choosing a linear guide system.

Helix Linear Technologies designs precision lead screws, custom machined & molded nuts, and linear actuators to suit specific application characteristics.

Listed below are the questions and answers to the top 11 linear actuator questions that are always being asked by customers and engineers.

Designed to increase productivity and precision, these steps are in place to ensure that your linear actuator systems are reliable in the medical industry

This blog post takes a closer look at some of the ways that acme lead screws can help reduce cost, thereby leading to more affordable product designs.

Acme lead screws are understood to be the preferred solution for linear actuation. This blog will give a brief overview of acme lead screw lubricants.

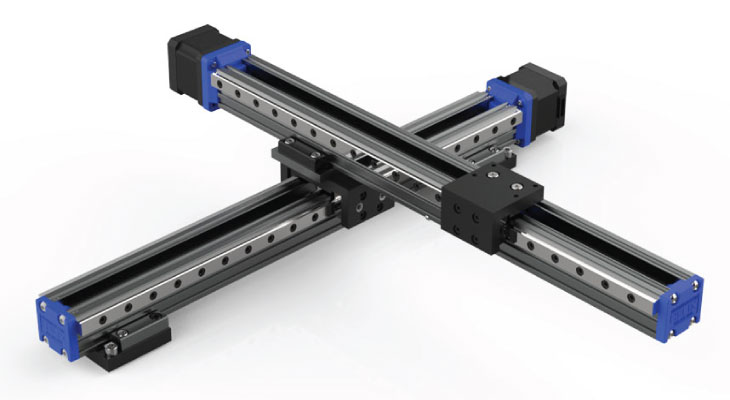

For position control in more than one direction, use the two-axis XY micro precision linear actuator or three-axis XYZ micro precision linear actuator.

The proper nut is just as important as the type of screw used. Learn how to make sure the trapezoidal screw and plastic nuts are chemically compatible.

Acme products may have had a connotation and made great results as demonstrated in Coyote's experience, Acme, as we know it today, is the opposite.

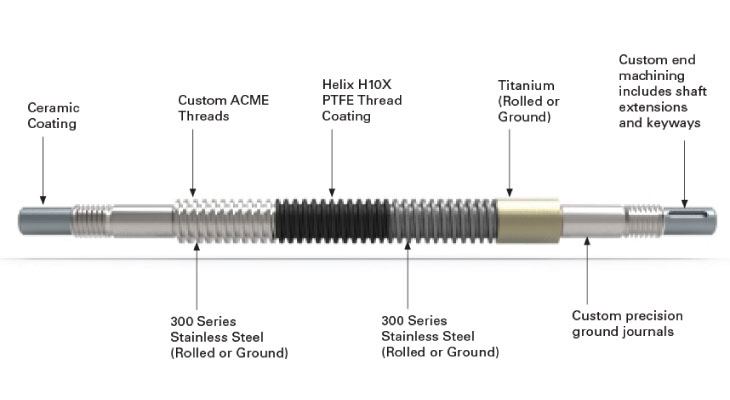

Helix PTFE H10X Lead Screw Coating is a fluoropolymer-based coating combined with unique formulated resins to provide the tough film for dry lubrication.

Learn about linear slide systems and what they do from these four common questions. These include types of lubrication to use and how slide systems can be modified.

Here's a closer look at some of the benefits of using stainless steel material for your acme lead screw and some of the stainless steel Helix offers.

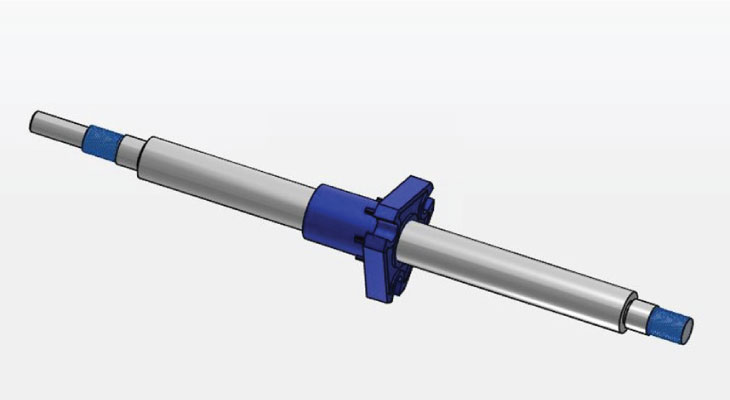

Torque splines are highly customizable multi-functional linear motion assemblies that are used to provide two axes of motion.

Download the new ISO 9001:2015 Design Certificate now to see what the quality advantages are. These include complete engineering, design, manufacturing and precision.

If you wish to enhance and evolve your linear motion systems, selecting the right style of anti-backlash nuts for your project depends on various factors.

Explore the new opportunities with the latest technology for motion exist because of lead screw efficiency in high-precision lead and acme screws

There are numerous benefits to leveraging precision ball screws in your applications. This blog explores five of the key benefits of these small components

Have a question about lead screws and acme screws? This blog effectively answers the top fifteen questions that you may ask about lead screws & acme screws

In this post, we're going to cover another important factor when it comes to screw selection - column strength.

Read about the invaluable role of a linear motion Application Engineer. Partner with Helix Linear Technologies for solutions and expert recommendations.

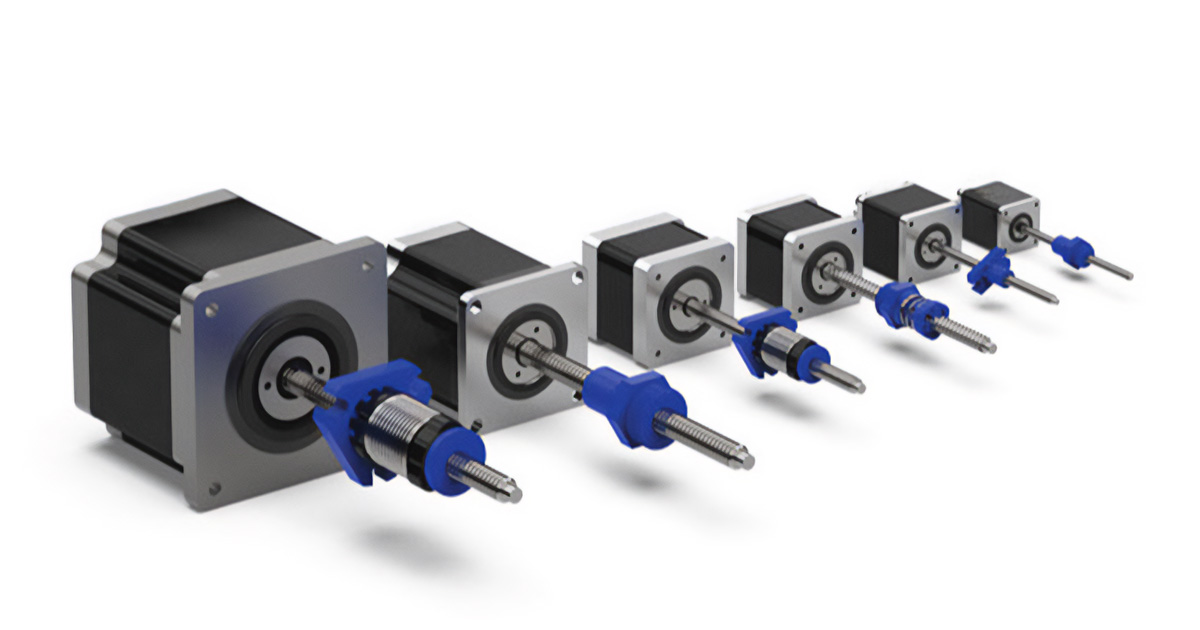

Discover the versatility of stepper motor linear actuators ranging from 2.1V to 12V. These helpful applications can allow you to achieve speed and accuracy.

Design for Manufacturing (DFM) is an engineering framework that optimizes the manufacturing process via design alterations in early stages of production.

There are many options for mounting with acme lead screws. However, there are four different ways combinations of end mounting that can commonly help you.

Get answers to your top profile rail questions with Helix's FAQ Friday. From seals to coatings, learn answers to the profile rail linear actuators questions.

Critical speed is typically considered after the load, speed, length and end fixity are thoroughly identified. These factors continue to impact lead screws.

Reviewing the characteristics of lead screws vs. ball screws can help you select the right screw-driven system for your linear motion application.

Linear actuators and leadscrew assemblies are vital for industries. They are clean, cost-effective, accurate and do not make loud noises to disrupt employees.

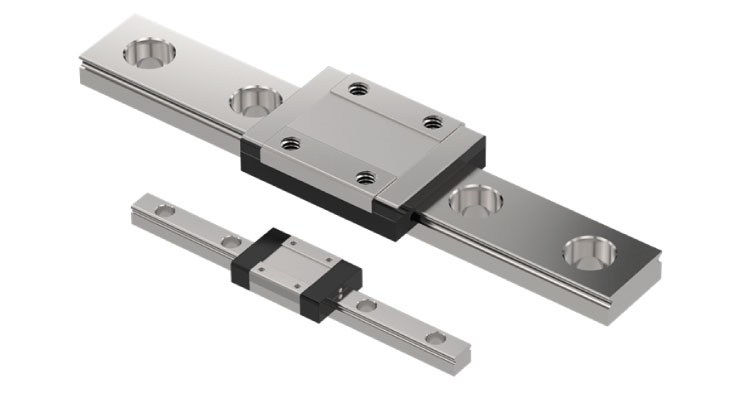

The all-new Helix Miniature Linear Guide offers the precision and accuracy that design engineers and product developers yearn for, furthering enhancement!

To enhance your projects and applications, lead screw coating is important. Learn how Helix Linear Technologies PTFE coating may be the right one for you.

The advantages of linear motion components in aerospace applications include high accuracy, quiet operation and an easy interface into existing systems.

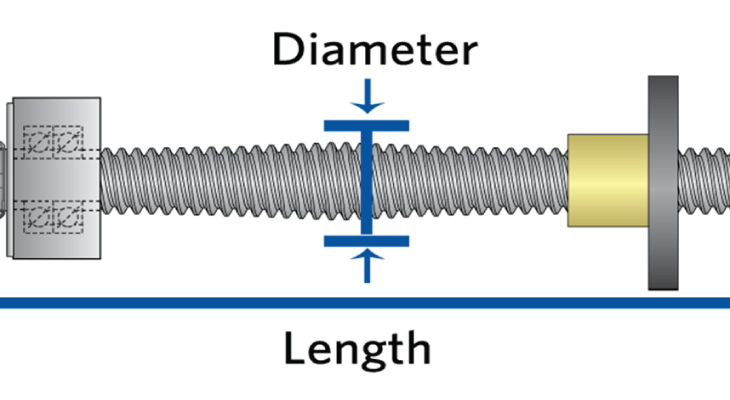

Continue reading this blog post to know how to determine which lead screw pitch length and lead thread start is right for your application.

Aluminum lead screws are an ideal solution in various industries for lightweight or non-magnetic applications. Learn more about lead screw efficiency here!

Using our special customization features, you can build your own lead screw in just three clicks and download it in over 100 different file formats!

The right lead screw can give your application more benefits. Helix offers the most variety of rolled acme and precision lead screws in the industry.

ASIMO is a bipedal humanoid robot Honda has been developing robots that will coexist with and be useful to people since its first introduction in 2000.

Helix Linear Technologies is formally announcing the separation from its affiliated company Nook Industries.

We all know sometimes it can be hard to find the right anti-backlash lead screw nut for your application. This blog post will help you make that choice.

It can be difficult to determine the best linear guide system for your application. Helix Linear Technologies explains what to consider so you can choose correctly.

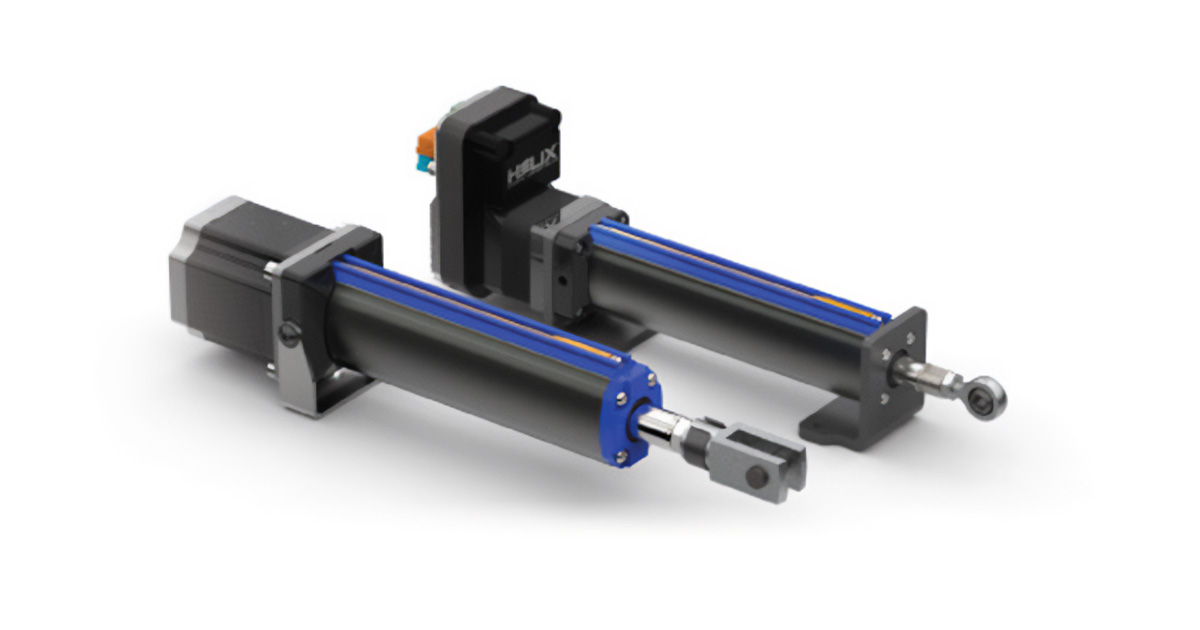

Learn the advantages of Electric Cylinders and why you should use them, including precise control, compact size and versatility for various applications.

You may benefit from Helix Linear Technologies' solutions for chemical processing applications. Our linear motion components save time, money and materials.

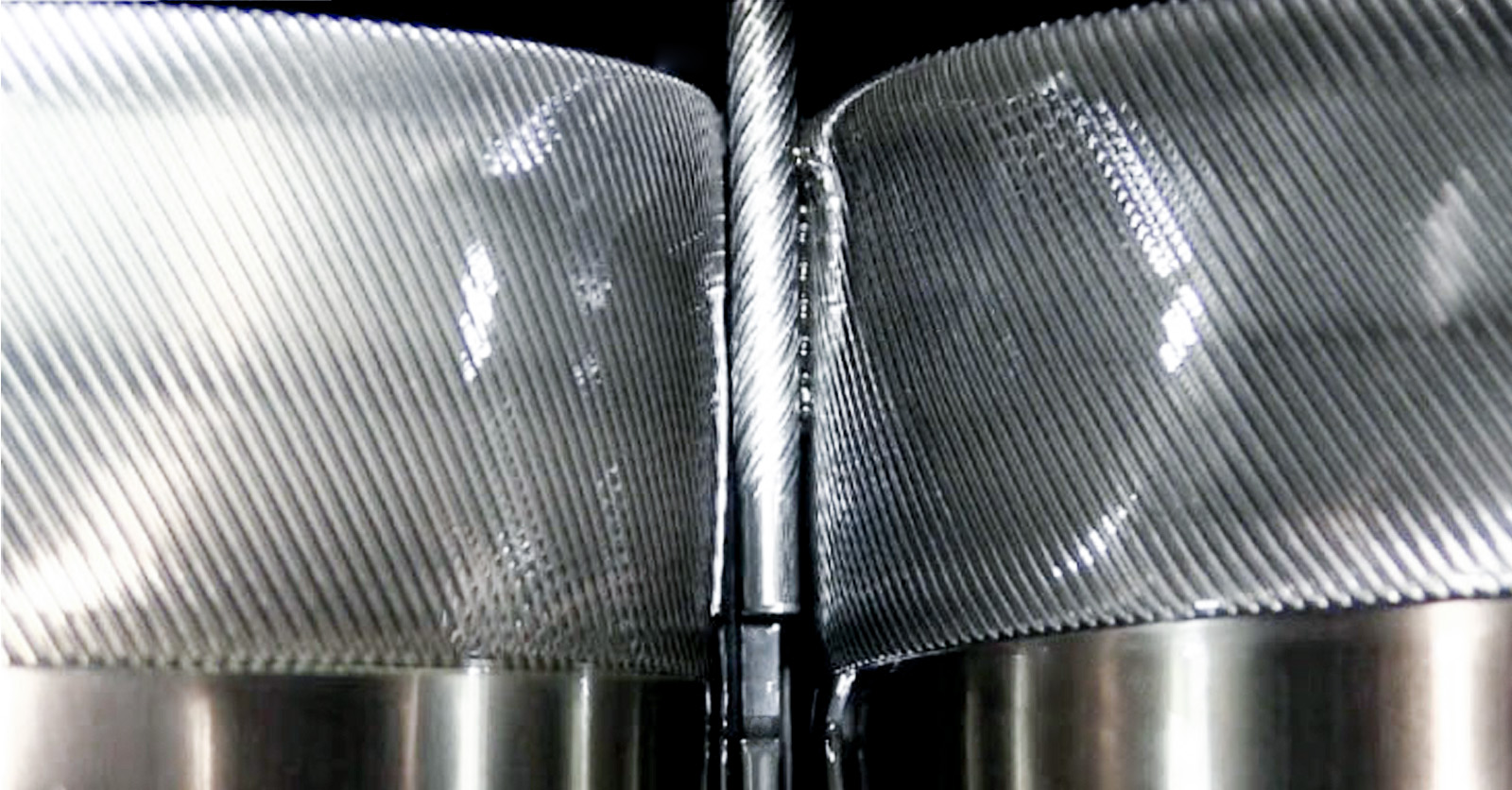

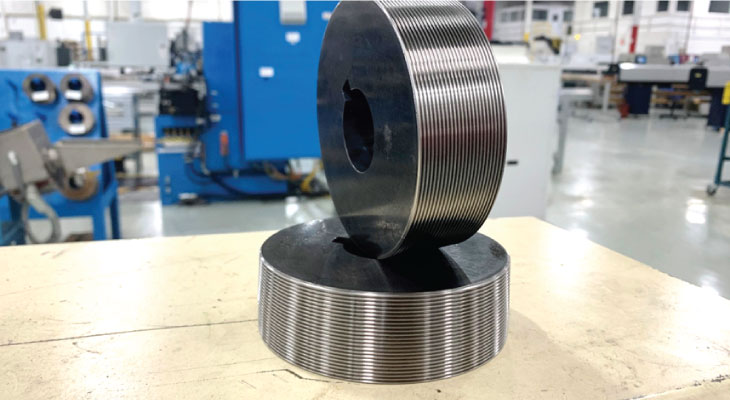

Thread rolling is a metal forging process that forms lead screw threads by passing material under high pressure through a set of hardened dies.

Pneumatic actuators have been the staple of the industry for years and have been sold as being compact, fast, and low cost.

Helix Linear has a wide variety of standard acme nut designs which offer many features and options to choose from. We also offer custom-made nut options!

Understanding the different types of acme thread types can better prepare you for your next linear motion application. Read this for in-depth information!

A stepper motor is one of the most common motors used in motion control applications, primarily positioning applications.

The essential steps and considerations required to choose the correct size and configuration for a stepper motor linear actuator for your applications.

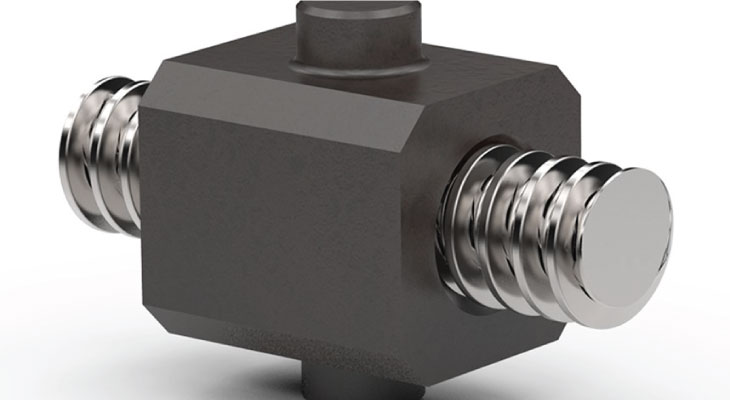

Ball screws play a crucial role in converting rotary motion into linear motion, enabling the smooth and accurate operation of various machines.

Miniature ball screws play a crucial role in many applications and it's important to understand their key features and benefits to make the best selection for your application.

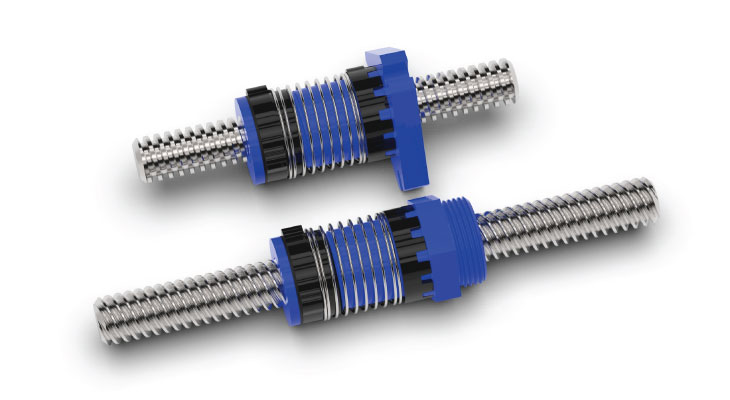

Engineering and designing systems that eliminate unwanted motion, such as antibacklash, is crucial to ensure optimal performance and reliability.

The journey of unlocking the potential of ball screw linear actuators for cutting-edge engineering projects.

Lubricants are important for protecting your lead screw from wearing down, but it can be challenging to know which one to choose. Learn which is best for you.

Lead screws play a vital role in mechanical systems, converting rotary motion into linear motion. Understanding lead threads can help elevate your project!

In missile fin actuation, ball screws are used to control the movement of the fins: crucial components that help steer and stabilize the missile in flight.

A ball screw linear actuator is a linear motion device that consists of a ball screw and a nut that rotates on the screw and used in various applications.

Ball screws are an essential component in a wide range of machinery and industrial applications. Ball screws have many benefits for linear motion projects.

When selecting a lead screw, one crucial consideration is the type of thread used. With the help of Helix Linear, choosing the correct lead screw is easy!

Learn how ball screws enable precise control of missile fin actuation, enhancing stability and targeting accuracy with high efficiency and reliability

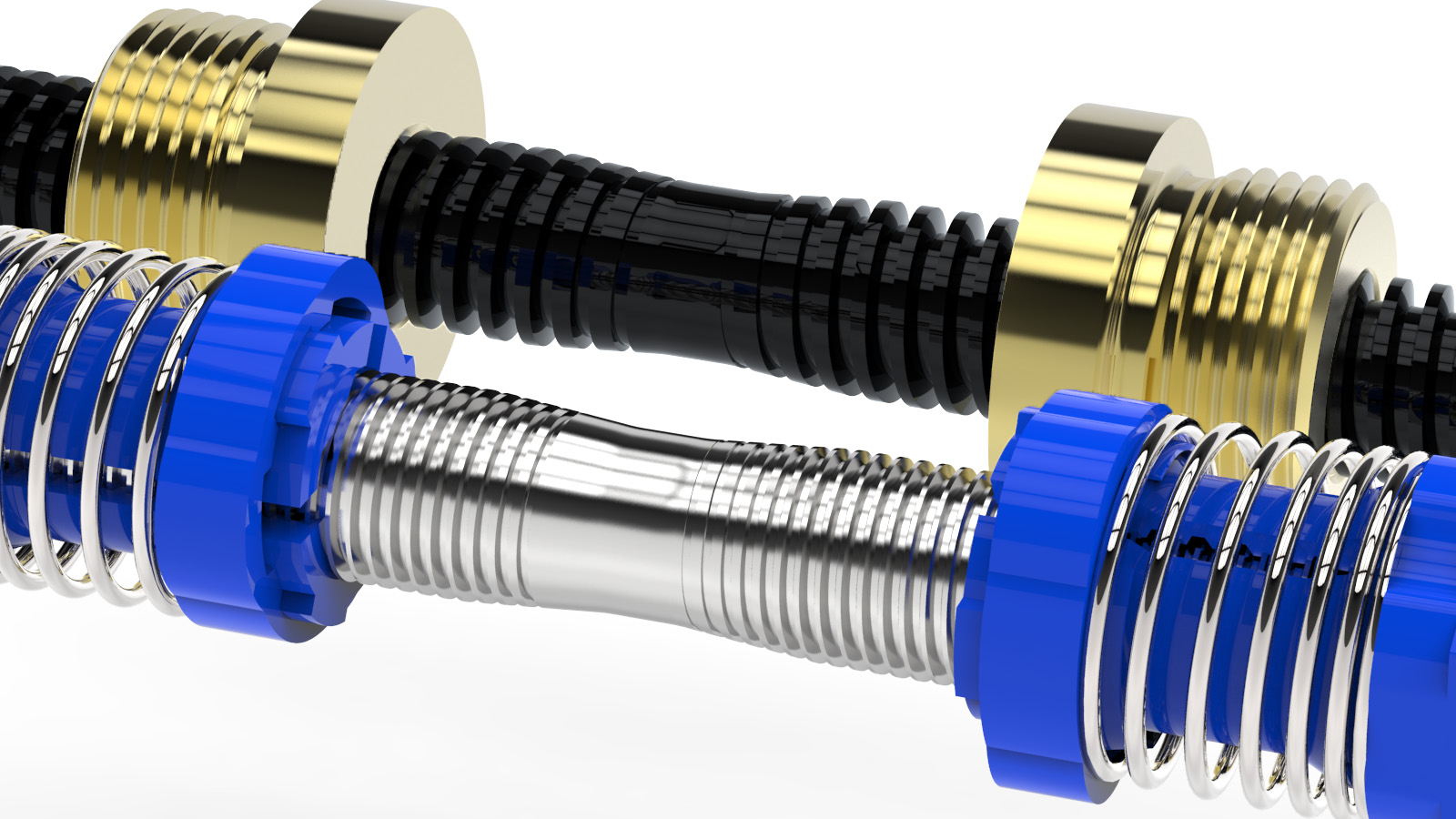

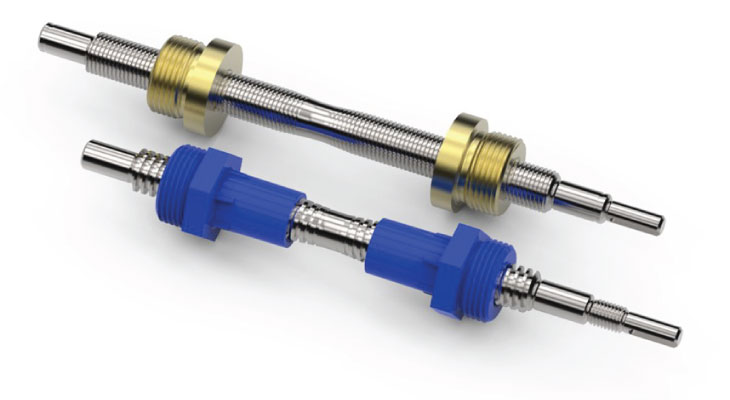

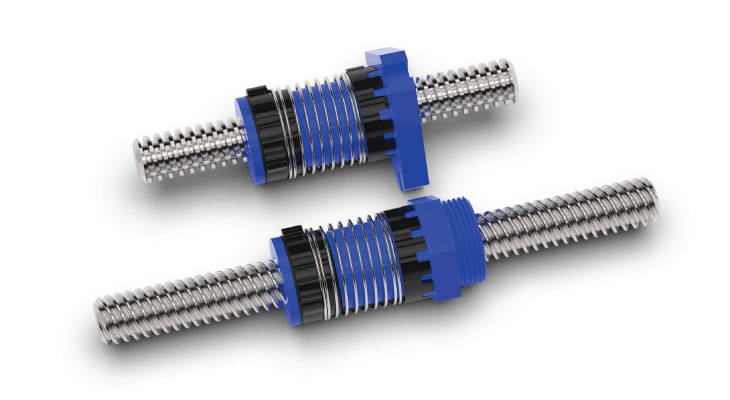

An in-depth description of what twin lead screws are and the various benefits they offer, resulting in enhancement and effectiveness in your applications.

It's easy to overlook small mistakes when designing linear motion systems. Some examples of what you should double-check are torque, temperature and overdriving.

Four helpful and crucial things that every engineer should keep in mind when selecting any lead screw for their diverse applications for effectiveness.

Ph.D. student in mechanical engineering Joseph Norby explains how his team created a galago-inspired jumping robot using advanced technology.

Helix Linear Technologies lead screws allow medical manufacturers to have flexible, modular linear motion control to respond to new product development.

This short video shows you how to efficiently and effectively use Solidworks to make an enhanced lead screw with a stepper motor.

Helix has combined manufacturing technology, and standard lead screw components to make low volume runs an affordable modern option.

The common elements that go into end machining with lead screws and other concepts that should be considered when using lead screws in your applications.

The unique pros and cons of each method so that you can understand and decide which option would best suit you for your particular diverse applications.

Helix Linear Technologies has designed a family of standard machined ends applicable to a variety of bearing arrangements so that you can have best results.

Electric linear actuators are a preferred choice for converting rotary motion into linear motion and here are the four common uses and advantages.

This acme screw backlash survival guide will answer questions and give you the details you need to accommodate backlash in your linear motion design.

Bearing end supports for linear actuators is essential to your linear actuation application. They ensure load carrying capabilities and long life.

When selecting the appropriate size of a linear actuator, applying one general number to make a selection, such as a maximum load rating, is difficult.

You can easily improve Acme screw efficiency and reliance in order to make Acme screws comparable to ultra-efficient ball screws! Learn more by reading!

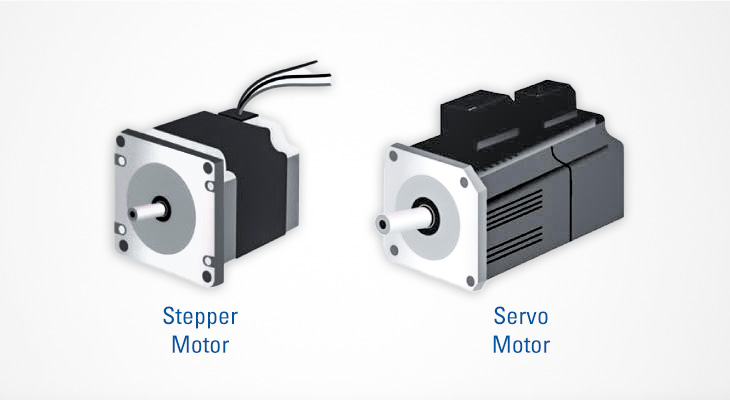

In this lesson, we will discuss the unique advantages and disadvantages of stepper motors compared to servo motors.

Motion control applications present challenges that require plastic acme nuts, which are made to provide lubrication, to make lead screws work better.

Twin lead screws from Helix Linear Technologies are designed to produce dual opposing motion using a single drive system, providing you the best results!

There are three main classes of Acme thread forms: General Purpose (G), Centralizing (C), and Stub Acme. This post will talk about these classes and more.

At Helix Linear Technologies, all of our thread-rolling dies are made right here in our facility in Beachwood, Ohio providing local & efficient production.

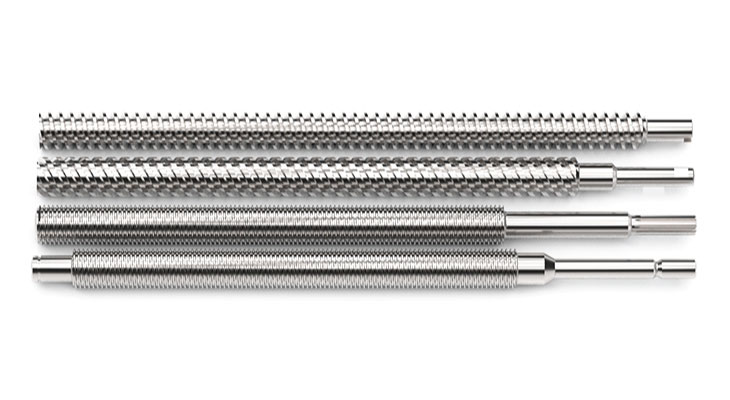

Helix Linear Technologies produces a full line of precision miniature lead screws for applications that demand micron-level positioning, offering precision.

The acme thread form, established over 100 years ago, replaced square thread screws, which had straight-sided flanks and were challenging to manufacture.

Helix Linear Technologies designs and manufactures custom lead screws and Acme screws in a variety of materials to meet the needs of your application.

Helix Linear Technologies is currently celebrating its fourth year manufacturing the small diameter Power AC Acme Screw product line.

Not sure which material to use for your acme nuts? Learn the basics of the materials used in acme nuts and how to compare them with a helpful PowerPoint.

When discussing precision lead screws, lead accuracy is the difference between the actual distances traveled vs. the theoretical distance traveled.

After getting together with some fellow Helix design engineers, we have come up with (what we deem to be) 3 cool projects for this class of linear actuator.

Proper lubrication is the key to the continued performance and reliability of lead screw assemblies, resulting in effective and efficient applications.

Acme screws are a mainstay for supplying motion and positioning control in many types of machinery. When choosing a screw, consider these factors below.

Before you can decide on what screws to use, you need to know how the characteristics of each match your specific application.

To assess which acme nut options will work for your application, you must evaluate how the characteristics of your design match up with acme nut features.

Here are answers to the Top 10 mechanical actuator questions we get asked:

Acme screws are the answer to linear motion needed in a lot of medical and diagnostics industry applications due to their precision and effectiveness!

Acme lead screws from Helix Linear Technologies provide a more focused, economical solution for integrating motion control systems in many new products.

Five things to consider during evaluation so that you know the motion control factors that can influence linear motion performance and effectiveness.

Helix Linear discusses the benefits of being an American-made manufacturer and how innovation is driving the recent resurgence in US manufacturing.

This blog post will give you a thorough understanding of how to efficiently and effectively evaluate the different acme screw assembly loads.

The important and commonly asked questions and answers about the use of lead screws for mechanical design so that you can get a deeper understanding!

A new generation of cost-effective precision lead screws and highly engineered plastic nuts are now available for automated security system applications.

Several trends are driving increased demand for electric actuators for providing linear motion control in packaging machines in order to reduce costs.

Learn about medical imaging systems, their challenges and ways to incorporate linear motion solutions into the applications for it to run the best it can.

Helix Linear Technologies' precision lead screws offer low cost, no need for lubrication, quieter operation, energy efficiency and design flexibility.

When it comes to choosing a lead screw design, there are many options to pick from. Here are five options that engineers have when they design a lead nut.

Acme lead screws come with a wide range of benefits that can positively impact your applications. Not only are they beneficial, but they're effective too!

The supply chain is very sensitive so it is important to reduce the risk of being line-down. This will keep your customers happy and coming back for more.

Read to learn about the benefits of hexapod use in motion applications and how to incorporate positioning platforms with Helix Linear Technologies' help.

In this blog, we explore our top five of the most popular questions from our “Ask an Engineer” weekly social media feature, with hopes of gaining knowledge

At Helix, we offer standard nuts manufactured from various materials as well as those that are custom-engineered from less conventional materials.

Lubrication is very important to the performance of lead screw assemblies. Here are the top five benefits of coating your acme lead screw with PTFE.

With a wide range of benefits, one could say acme lead screws come in many flavors. Here's a closer look at some of the many flavors you have available.

Many important factors need to be considered when making your acme screw selection. Characteristics such as backlash and lubrication can help you decide!

The medical field is advancing at a high rate. One of the components doing the most to propel the medical industry forward is the precision acme screw.

Helix Linear Acme lead screws drive linear motion innovation using a custom-blended thermoplastic material integrated with friction fighting PTFE.

Here we answer the questions regarding mounting options for Helix lead screw assemblies so that you can have a more productive and efficient experience!

A small linear actuator is a device that creates a linear or straight motion. Its compact size allows it to fit into tight compartments.

This blog post will explain what characteristics of an acme lead screw make it such a desirable piece of hardware in mechanically designed systems.

Mechanical components including lead screw(s), nuts & flanges and bearing supports, provide safety and cost-effective, time-proven door rail system designs.

Continue reading the rest of this blog if you want to learn how to choose the right lubricant for your acme screw so it can perform at its best.

How lead screw actuators enable rail car designs by utilizing and leveraging several solutions to rail car design challenges, resulting in world-class cars.

This article will examine how the use of linear actuators driven by lead screws is helping HVAC professionals meet the requirements of applications.

Helix Linear Technologies lead-screw actuators have the ability to help engineers everywhere redesign airline seating for weight reduction and comfort.

Choosing the right lead screw for your project can help you achieve more than you ever thought was possible, and with a little more knowledge, that is easy.

In nearly all cases, an electrical actuator will prove to be the better choice due to these 10 benefits that are listed below in this blog post.

Aside from car buffs, most people who drive automobiles have no idea that small electric actuators perform various automotive functions.

One of the more interesting applications of precision lead screws involves their use for driving the fin actuation that guides a missile to its target.

There are many benefits of using PTFE coated screws to improve and enhance your products and applications but these are the three main benefits to you!

Challenges in industrial robots that require enhanced linear motion control can be met by a new generation of precision-engineered lead screws.

The screw thread of a lead screw or Acme screw is a factor in configuring a mechanical actuator. Various screw thread forms and options are listed below.

A new generation of precision lead screws and highly engineered plastic nuts and are now widely available for syringe pump applications, offering results.

A closer look at the advantages and disadvantages of using an electric linear actuator or a pneumatic actuator to position components and move loads.

You must be able to have precise guidance and positioning with your linear motion control to be successful today. Learn how to select the best system.

Our Helix H10X coating is now available and offering productive results with the 10 reasons why our H10X coating is better than other leading manufactures.

Lead screws now offer many significant advantages over alternative technologies like ball screws. Let us help determine if a lead screw will work for you.

Even though the acme thread forms are proven to be a reliable and effective design for linear motion applications in aircraft.

Most common motion control mistakes can be avoided by following advice. It includes knowing control requirements and not choosing components because of price.

Are you considering using a lead screw in your design? If so, here are four things to keep in mind so that you can ensure the most positive results!

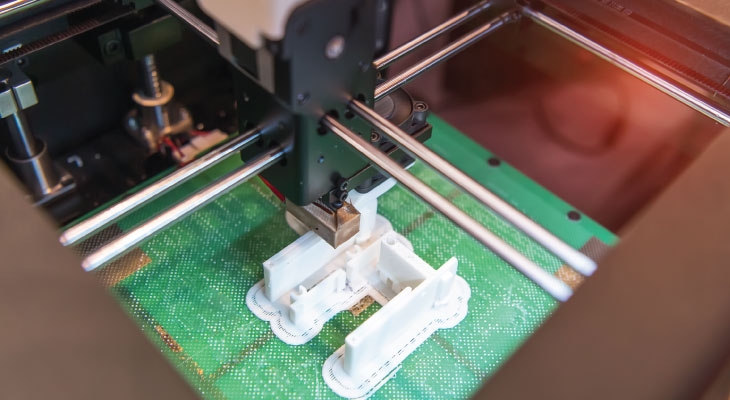

This article examines the advantages of using precision-engineered lead screws for driving linear motion control in 3D printing systems.

Helix Linear Technologies discusses the easiest way to select the best stepper motor linear actuator for your next big application, offering efficiency!

Helix Linear Technologies precision lead screws are now driving positive and effective results 250 miles above the Earth inside NASA's Refabricator project.

Speak to an Application Engineer

Our application engineers are here to help you plan, customize and select the optimal linear motion components for your additive manufacturing application.

Our Products

Helix Linear Technologies offers a wide range of linear motion products that are designed to make your next food and beverage handling application a success. Not sure what you need? No problem. We're here to help guide you every step of the way.

Downloads

Profile Rail Linear Actuator Catalog

Profile Rail Linear Actuator Catalog

Analyze the capabilities of profile rail linear actuators.

.png)

.png)