Electric Actuator or Pneumatic Actuator?

Many types of machinery need to position components and/or linearly move loads, and machine designers routinely face the question of whether to use an electric cylinder or a pneumatic actuator to fulfill this requirement.

Choosing the suitable actuator for the job is critical in today’s competitive global environment. Selection of the incorrect option can often translate into the loss of tens of thousands of dollars each year. Yet, the choice is often not obvious, nor is it easy to make. Both electric linear actuators and pneumatic actuators provide precise positioning and control, and both have proven track records in machine applications. Both technologies also have their advantages and disadvantages.

In order to make the right decision on whether to use an electric actuator or a pneumatic actuator, you need to thoroughly evaluate the performance, component cost, system cost, and productivity requirements of your specific linear motion control application. As well as gain an understanding of the advantages and disadvantages of each type of actuator.

The Advantages and Disadvantages of Electric Actuators

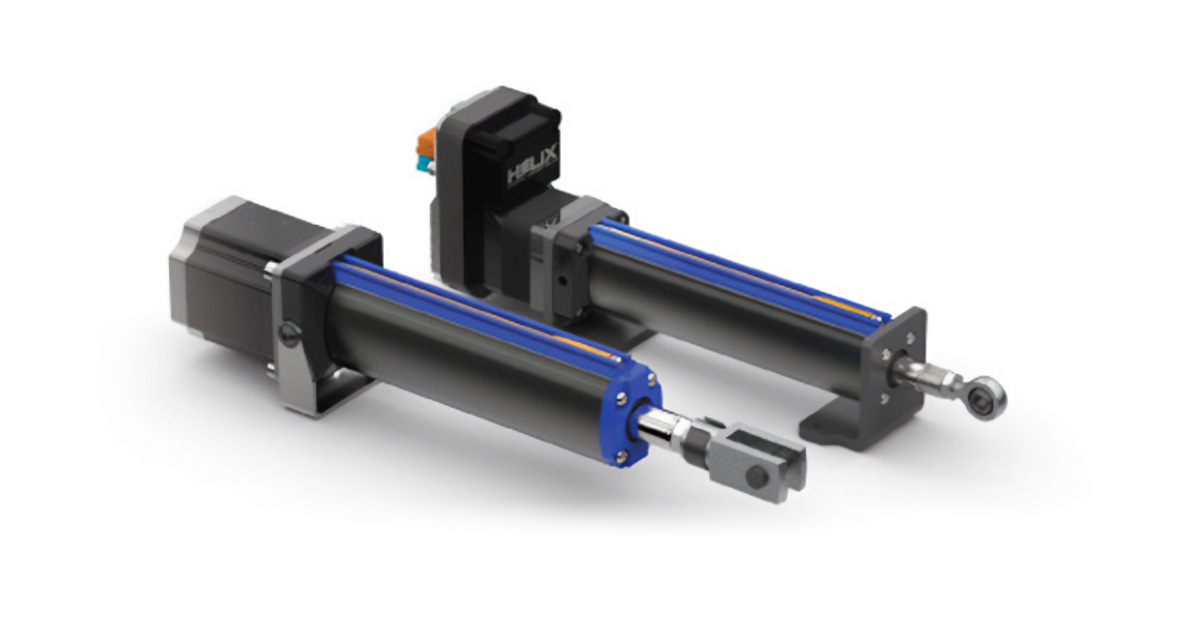

When evaluating the use of electric linear actuators, which are known to provide higher levels of precision, you must first assess the degree of precision required by your linear motion control system. Electric actuators generally use a ball screw, an Acme lead screw, and a roller screw driven by an electric motor, such as stepper motors and servomotors. As the screw turns, it moves a piston connected to the rod or carriage, which carries the load. The advantages and disadvantages of electric actuators include:

- A wide range of control options for the specific motion profile

- Better adaptability for machines that involve flexible processes and low operational costs

- Greater economy in moderate scale deployments that leverage their performance advantages

- Reduced replacement costs, particularly in applications in which the electronics are separate from the actuator

- More flexible drive options, such as using a more economical stepper motor for accurate positioning at lower speeds, or a more costly servomotor for superior performance at high speeds

- Greater accuracy through the use of high-precision lead screws and anti-backlash lead screw nuts. which can provide accuracy to ten-thousandths of an inch.

- Predictable operating energy costs, primarily related to motor power draw

- High component costs

- Low operational costs

The Advantages and Disadvantages of Pneumatic Actuators

In linear motion control applications for which high precision is not as critical, pneumatic actuators provide high force and speed in a compact footprint. Pneumatic actuators utilize a pneumatic cylinder driven by compressed air, with typical forces ranging from 20 to4,000 pounds. The only other actuation technology that can produce more force and speed per unit is hydraulic-driven actuation. The pros and cons of pneumatic actuators include:

- High force and speed with a defined stroke and quick response

- Greater economy when the number of cylinders is scaled to match compressor capacity

- Costly when compressor capacity is not fully utilized, with additional costs incurred when a compressor sits idling (when the load is not being moved)

- Low component costs

- High operational costs

- High maintenance costs

- Wastes a substantial amount of electricity when the compressor is idling or when the pneumatic system is inadequately maintained, resulting in air leaks

Assessing Costs

When assessing the costs of electric linear actuators and pneumatic actuators, it’s essential to look beyond the initial component costs for each system. Maintenance and operating costs for pneumatic actuator systems are much higher than those associated with the electric variety. For example, manual changeovers of pneumatic actuators are costly due to the loss of production and the personnel required to perform the transformations. Because electric linear actuators are more conducive to modular design and easier to maintain, they can substantially reduce changeover costs. These savings should be factored into your implementation decision.

Choosing the Right Actuator for the Job

Prudent machine designers thoroughly explore both options before making design and purchasing decisions. Although electric systems carry higher component costs than pneumatic actuators, the savings associated with their lower operational and maintenance costs, combined with the modular design freedom they afford to machine designers, typically more than offset the higher upfront costs.

To learn more about the differences, advantages, and disadvantages of electric and pneumatic actuators consult with a Helix Linear Technologies application engineer today.