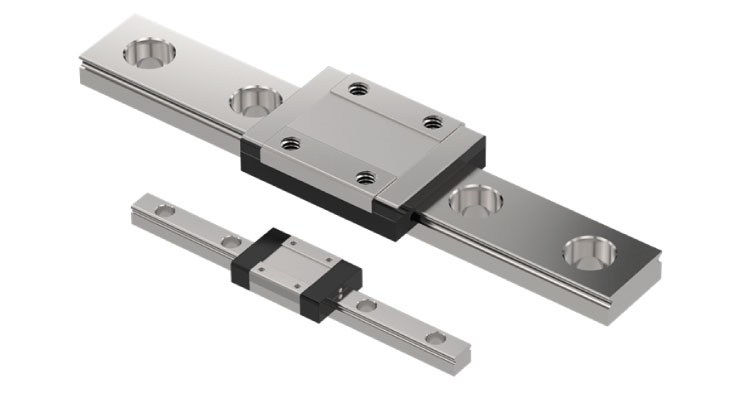

Introducing the New Helix Miniature Linear Guides

What do you get when compact design meets flexibility? The all-new Helix Miniature Linear Guide. This new family of linear guidance products offers the precision and accuracy that design engineers and product developers yearn for, with the flexibility they can't get from other linear guidance systems.

- Unique design: These miniature guides consist of a ball re-circulating design and an innovative embedded inverse hook design, which helps to reduce noise significantly. At the same time, extend life, reduce maintenance and improve high-speed running capability.

- Reinforced plates: The HMR-EE series stainless steel reinforced plates help make this product line robust and enable the operation of high running speeds.

- Lubrication: Included in the design is an embedded lubrication pad, which works to oil balls, the raceway, and provides many options for machine design.

- Greater surface contact: This feature allows the miniature guides to work with high load and high moment capacity compared to competing products.

- Dust-proof: We already told you about how this new product line from Helix reduces maintenance - and its dust-free offering only furthers that benefit. They are designed, so that dust contamination is restricted, thereby enabling prolonged life.

Linear guidance was conceptualized as early as prehistoric times to transport stones more effectively and efficiently. The rolling element that today's guides employ can be traced back to ancient Egypt, as workers used logs to lift and transport heavy cargo in a way that mirrors the use of today's linear guidance technology. Linear guides have come a long way and took off in terms of innovation and development in the 20th century as linear motion bearings began employing steel balls for small and accelerated movement. Development and improvement to existing designs persisted into the 1900s, with each generation of innovation improving upon the last.

Now Helix is pleased to present its new Miniature Linear Guide product line, a next-generation product that can aid precision applications unlike anything else available in the marketplace. This product line's unique design and flexibility can take your linear motion application to the next level.

Visit Helix's website to configure a CAD model of a product specific to your application requirements, download and analyze 3D models and drawings, view product specifications, and use this wealth of information to help you decide on the right Helix Miniature Linear Guide for your application.