Five Awesome Lead Screw Designs Specifically For You!

One of the benefits of using a lead screw to automate an axis of your machine is that the design options are endless! Design engineers can do virtually anything with the nut design as long as it incorporates the mating thread of the screw.

Lead Screw Nut Design Options

Here are just a few of the options that engineers have when they design a lead screw nut:

- Materials: PEEK®, polyester, PVDF, Vespel®, Ertalyte®, Torlon®, bronze, aluminum, steel, stainless steel, and brass

- Manufacturing method: machined or molded

- Insert Molding: add metal components to the nut in the molding process

- Precision: freewheeling or anti-backlash

- Temperature ranges: -40° F to 550° F

Lead screws also offer a wide array of design options:

- Materials: stainless steel, alloy steel, aluminum, brass, bronze, plastic

- Manufacturing Method: rolled, ground, milled, machined

- Alternate Machining Options: friction welding (dissimilar materials can be combined to reduce overall costs)

- Precision: .0003"/ inch (Higher accuracy upon request)

- Lubricants: PTFE, TFE

- Protective Coatings: Black Oxide, Melanite (salt bath ferritic nitrocarburizing) Duracoat®, Cerakote™, nickel, chrome, Armalloy®

- Temperature ranges: -40° F to 550° F

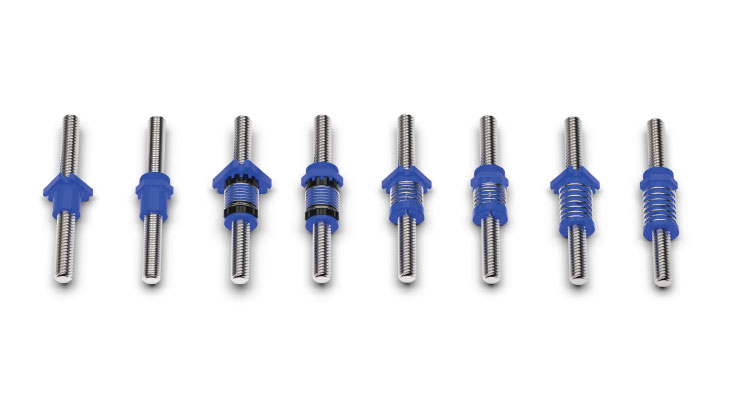

Below are five examples of really outstanding designs...

Example One

- Nut material: aluminum - 6061

- Hollow screw: reduced overall assembly weight by approximately 50%

- Screw material: 4140

- Screw diameter: 0.500"

- Screw lead: 0.500"

- Starts: Five

- Length: 5.00”

What makes it awesome? It was rolled out of a hollow piece of material, making it a low-cost solution for reducing weight.

Example Two

- Nut material: custom acetal blend

- Twin lead screw: left and right-hand thread

- Screw material: 303 stainless

- Screw diameter: 0.250”

- Screw lead: 0.078"

- Starts: Two

- Length: 3.00"

What makes it awesome? It's a miniature twin screw assembly that delivers opposite directions of movement simultaneously.

Example Three

- Screw material: 303 stainless

- Screw diameter: 0.125”

- Screw lead: 0.096”

- Starts: Four

- Length: 1.62”

What makes it awesome? The miniature trunion-mounted nut, the precision machining on the end of the screw, and the high lead.

Example Four

- Nut material: Acetal

- Screw material: 303 stainless

- Screw diameter: 0.125”

- Screw lead: 0.096”

- Starts: Four

- Length: 3.5”

What makes it awesome? The nut design incorporates several other components into the nut itself and reduces the overall BOM.

Example Five

- Nut Material: Polyamide Nylon/Kevlar with Aramid and Molybdenum Disulphide fill (say that three times fast)

- Screw material: aluminum

- Coating: PTFE dry lubricant

- Screw diameter: 11mm

- Screw lead: 4mm

- Starts: One

- Length: 308mm

What makes it awesome? This nut is as tough as it gets when it comes to resisting high-impact loads. The screw is rolled out of 6061 aluminum, and the drive end of the screw eliminates the need for a coupling. It's also coated in a PTFE dry lubricant.

Lead screws offer engineers excellent options for custom linear motion solutions. These screws are as precise as .0003" / inch ( higher accuracy upon request) positioning accuracy. They are also a straightforward solution for converting rotary motion to linear motion with the added benefit of incredibly smooth and quiet operation compared to ball screws. Lead screws are also an excellent solution for "clean" applications where particulation and out-gassing are unacceptable. The next time you consider using a screw as a means of linear motion for your machine, remember the many design options you have at your disposal.