Why is Thread Rolling important process for Lead Screws?

Thread rolling is a metal forging process that forms leas screw threads by passing material under high pressure through a set of hardened dies. In the thread rolling machine, dies are skewed or pitched relative to one another, so their axes are not parallel. The skew is responsible for translating the material through the dies in what is termed as a thru-feed process. The rolling dies are designed to control the feed rate of the material passing through them, which regulates how long the rolled material stays in the dies and establishes the speed at which the thread is formed. Rolling dies are an essential part of the die design process, given the variety of thread sizes, depths, shapes, and material being rolled.

What are the benefits of thread rolling?

Thread rolling is an economical way to manufacture precision lead screws. It is ideal for producing long threaded lengths. Precision threads can be rolled at the rate of several feet per minute. However, machining and grinding operations are much slower processes for creating threads and more complicated when threading long lengths because of machine capability and length-to-diameter ratios.

Additional benefits of thread-rolling include:

Time Savings - Regardless of thread depth, rolling produces the final thread in one pass through the dies, whereas cutting and grinding processes may require several passes before achieving full thread depth. When producing multi-start threads, the time difference is even more significant. Many lead screws can have two to four starts and some as many as sixteen starts. All starts are formed at once during the thread rolling process, regardless of the number of starts. However, when using machining or grinding methods, all starts are produced individually, multiplying the time it takes to make the threads. In addition to the time savings, cutting the threads individually can introduce thread-to-thread or pitch to pitch errors.

High-Quality Finish - The rolling process produces a superior burnished finish. Burnishing is a mechanical polishing that improves the surface quality as the dies compress and form the rolled material. The surface finish is important because many of the nuts engaging a leadscrew are plastic, and high-quality finishes provide improved wear resistance. The burnished finish also reduces the friction coefficient, increasing overall efficiency by 8%-9%. In addition, the accuracy and finish of this process provide optimum output, producing lead screws that are smoother and longer-lasting.

Material Strength - No material is removed during the rolling process, and it changes the material's physical properties, resulting in the metal being work hardened. This condition produces a more substantial thread and improves the surface hardness of the lead screw. The more rigid surface enhances wear resistance and works well with alternative nut materials.

No Seam - In addition to the added strength of the rolled material, another benefit of thread rolling is the absence of a seam at the crest of the screw threads. Low-quality lead screws that don't require precision are rolled to control the pitch diameter but allow the major diameter to fluctuate. This variation exposes a seam at the top of the thread, ranging from barely visible to more substantial. While this practice improves die life, it results in variation in the major diameter and is not optimal for plastic nuts on centralizing threads where there may be contacted on this surface. Precision thread rolling closes this seam through design and increased pressure. This process of filling the dies sacrifices die life but improves the overall accuracy of the product's diameter, finish, and appearance.

Thread Rolling Material and Preparation

Threads can be rolled using stainless steel, carbon steel, aluminum, titanium, or other rod stock materials. Stainless steel is commonly used to roll lead screws. However, application-specific materials can be selected to meet specific project requirements. Although some adjustments in the rolling process may allow the same rolling dies to be used for several different materials, new dies may be required when differences in material hardness, malleability, and ductile properties are present.

The expression "garbage in, garbage out" aptly applies to the precision thread rolling process. The diameter and roundness of the blank being fed through the dies are essential. A separate centerless grinding operation on the rod stock is required to control tight tolerances on the blank diameter and rod roundness. Both specs should be held to .0002" or 5 microns.

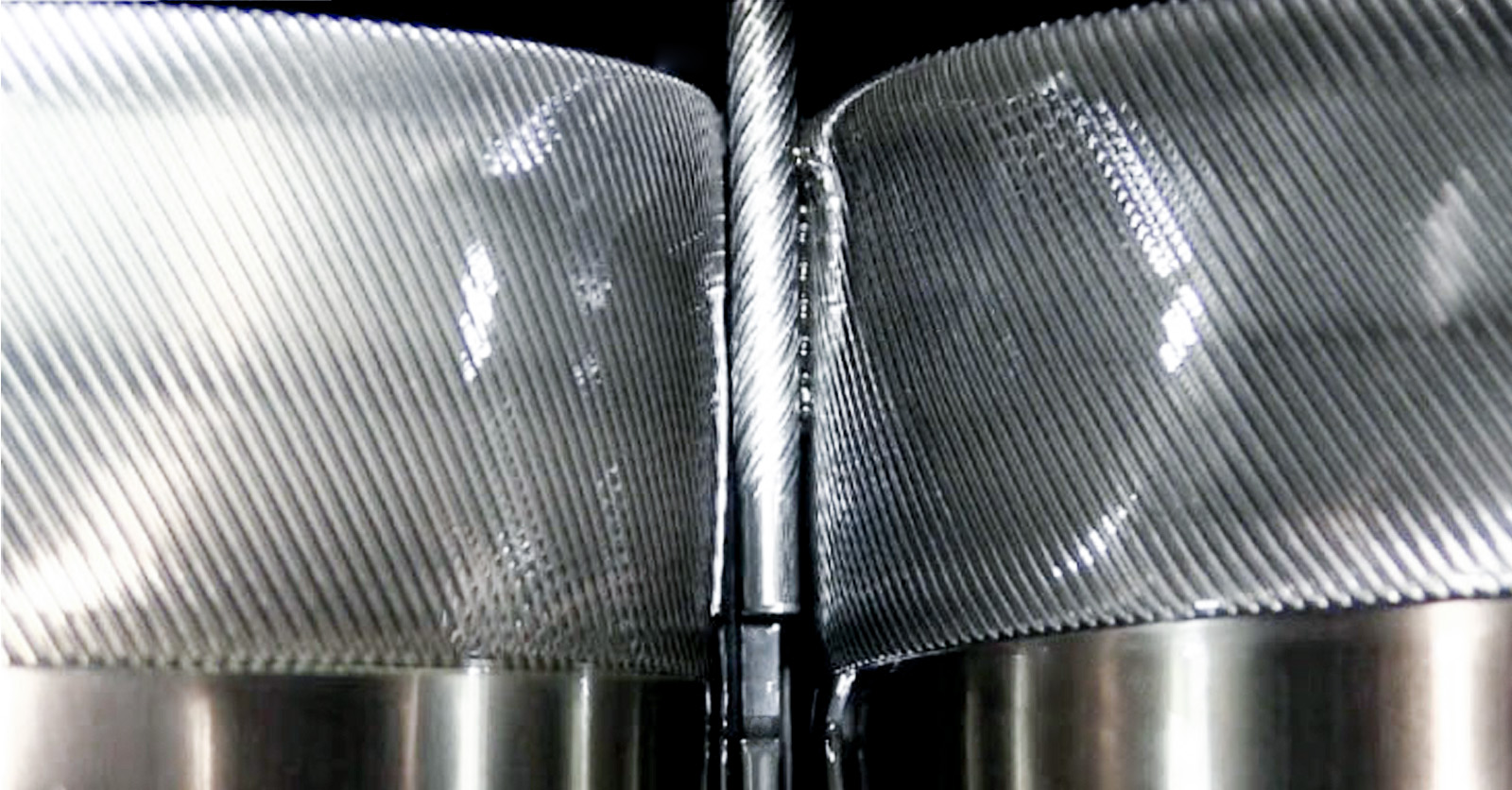

How are Thread Rolling Dies Made?

Dies are typically made by hobbing or grinding. Hobbing the dies cut the impression of the thread shape into the tool steel. The accuracy of the finished die relies heavily on the quality of the hob. Usually, a polishing or lapping process is necessary to improve the finish after machining. With hobbing, one die is cut at a time, creating some variability in the set.

Thread rolling dies are heat-treated to achieve a greater hardness than the rolled material. Heat treating is completed after hobbing, which can influence the final accuracy. Using suitable material and heat-treating process significantly increases die life, especially in dies that roll fine-pitch threads or very coarse (high helix angle) threads. Both thread extremes inherently put more stress on the dies.

Grinding the dies is generally more accurate, and tighter tolerances can be obtained. The grinding process produces a better surface finish without secondary polishing. Also, the dies are ground after hardening, eliminating some unpredictability or variability from the heat treatment process.

Types of Thread Rolling Systems

Thread rolling systems generally fall into three categories: flat roll plates, two-die, or three-die systems.

Flat Roll Plates - Flat rolling plates are utilized in high-speed, low-accuracy applications like threading fasteners, mechanical screws, and bolts.

Three-Die Rolling - A three-die rolling system provides high rolling accuracy and roundness. Still, it can be prohibitive when producing small diameter leadscrews due to the limitation of how close the three dies can get to each other. Smaller diameter dies can help, but there are still size limitations. In addition, due to equipment arbor sizes and die wear/life considerations, smaller dies often create additional challenges.

Two-Die Rolling - A two-die rolling system provides superior results and the greatest flexibility for rolling high-accuracy lead screws and accommodating smaller diameters. Another advantage of the two-die system is reduced tooling costs. As lead screw diameters increase in size, so do the corresponding dies used to roll them. It is less expensive to manufacture a set of two dies compared to three dies. The two-die system requires a blade to support the material as it is being rolled. However, this trade-off is far outweighed by its advantages.

Helix Linear Technologies offers the broadest range of leadscrew diameters, leads, and thread forms. We produce all of our thread rolling dies in-house and specialize in engineered thread forms designed to meet our customers' specific application requirements. This internal capability allows us to design and produce rolling dies quickly, resulting in rolled material within one week in some situations.

Precision-rolled lead screws offer engineers and machine designers high-quality, cost-effective options for their linear motion requirements. Contact a Helix Linear Technologies Application engineer today for a consultation.