A Closer Look at Twin-Lead Acme Screws!

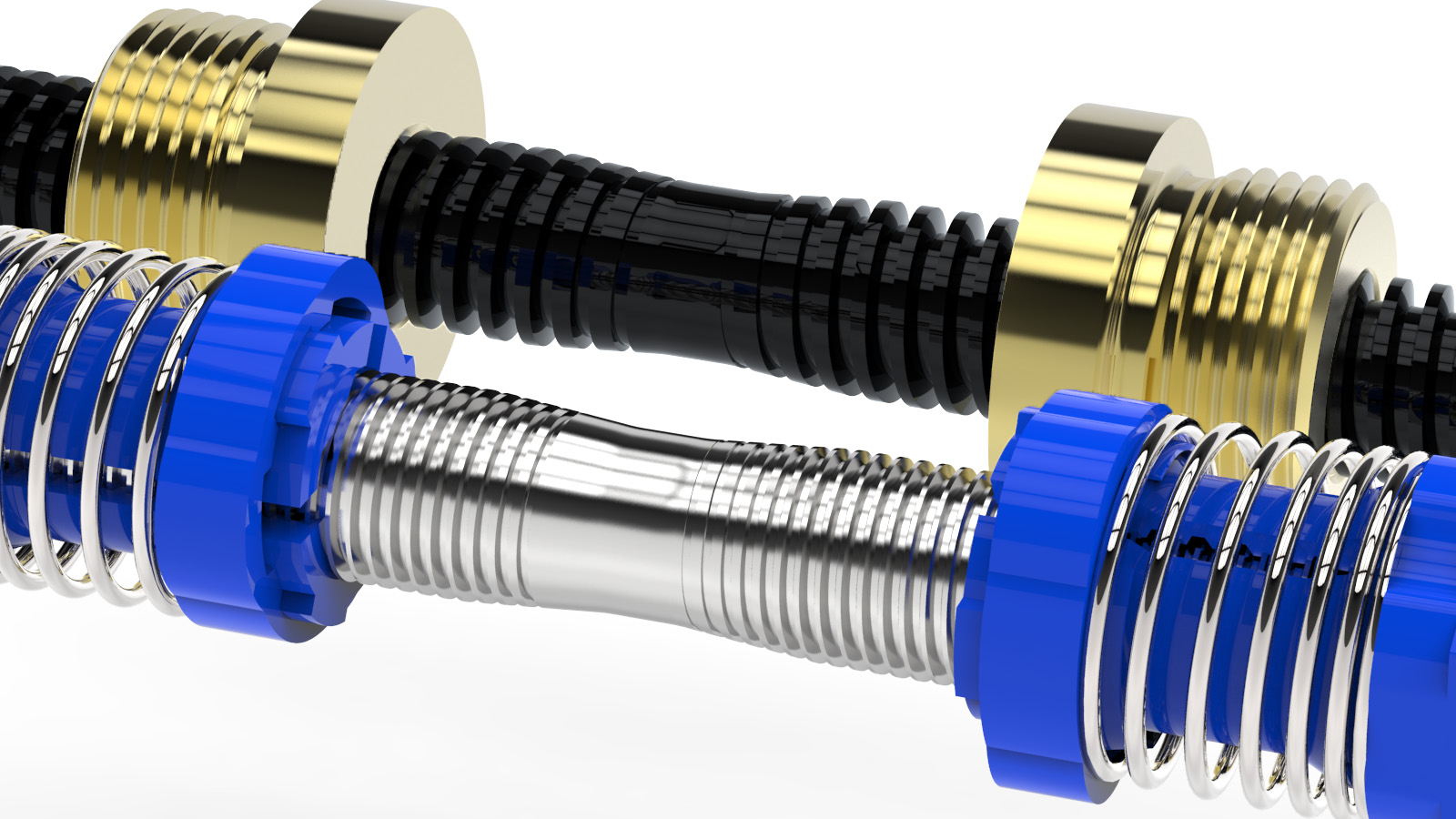

Twin lead screws from Helix Linear technologies offer dual opposing motion using a single drive system. That's right - simultaneous right and left movement from a centerline, but on a single drive system or motor. This one-piece screw is designed for high-performance applications, offering several advantages, including easy, convenient installation and elimination of alignment problems with segmented versions.

Twin-lead Acme screws are typically made from alloy steel and black oxidized for further protection. Depending on the intended application, they can be easily assembled with the various nuts, flanges, and EZZE-MOUNT bearing supports to offer enhanced support cost-effectively.

Twin lead screws are ideal for high-performance applications with low-duty cycles or manual drive operation. Some popular applications include:

- Molding machines

- Packaging equipment

- Food processing machinery

- Robotics

- Material handling applications

- Tire manufacturing

Twin lead screws from Helix Linear can be completely tailored to fit the requirements of your application. Customizations include material, thread form, end-machining, coatings, nut type, nut material, and mounting options. The most popular kind of twin lead Acme screws are thread-rolled screws. Thread-rolled twin lead screws offer a standard lead accuracy of 0.0003 inches but can be modified for additional accuracy. Rolled twin lead screws are more economical than ground screws making them a cost-effective option.

Features and benefits of using twin-lead acme screws include:

- Available in sizes from 2-50mm diameter

- Standard screw materials: 300 series stainless steel, 4140 alloy, aluminum, and titanium.

- Helix H4X PTFE coating available

- Assembled with standard or anti-backlash nuts

- End machining available

- Easy installation

- Easy elimination of alignment problems