The Best Helix Standard Mounting Options for Acme Screws

Various factors need to be considered to ensure that Acme lead screws serve a particular application correctly. There are four primary things to consider regarding lead screw selection: load, speed, length of travel, and end fixity. This article will take a closer look at end fixity and how it relates to the proper mounting of your lead screw assemblies. These same principles also apply to selecting the best ball screw for your application.

For this discussion, we will define end fixity as the method by which the ends of the acme lead screw are supported within a given linear motion application.

There are many options for lead screw mounting, and it is impractical to cover them all in a single post. So in this article, we'll cover four of the most used combinations of end mounting. As an overview, there are four basic types of end fixity:

1. Fixed/Free2. Simple/Simple

3. Fixed/Simple

4. Fixed/Fixed

Each combination affects the system's rigidity, which affects the speed at which the system can run and the system's load capacity. When a system has high rigidity, it can operate at higher speeds and handle larger load capacities. The descriptions and illustrations below are listed in order of the lowest rigidity to the most increased rigidity.

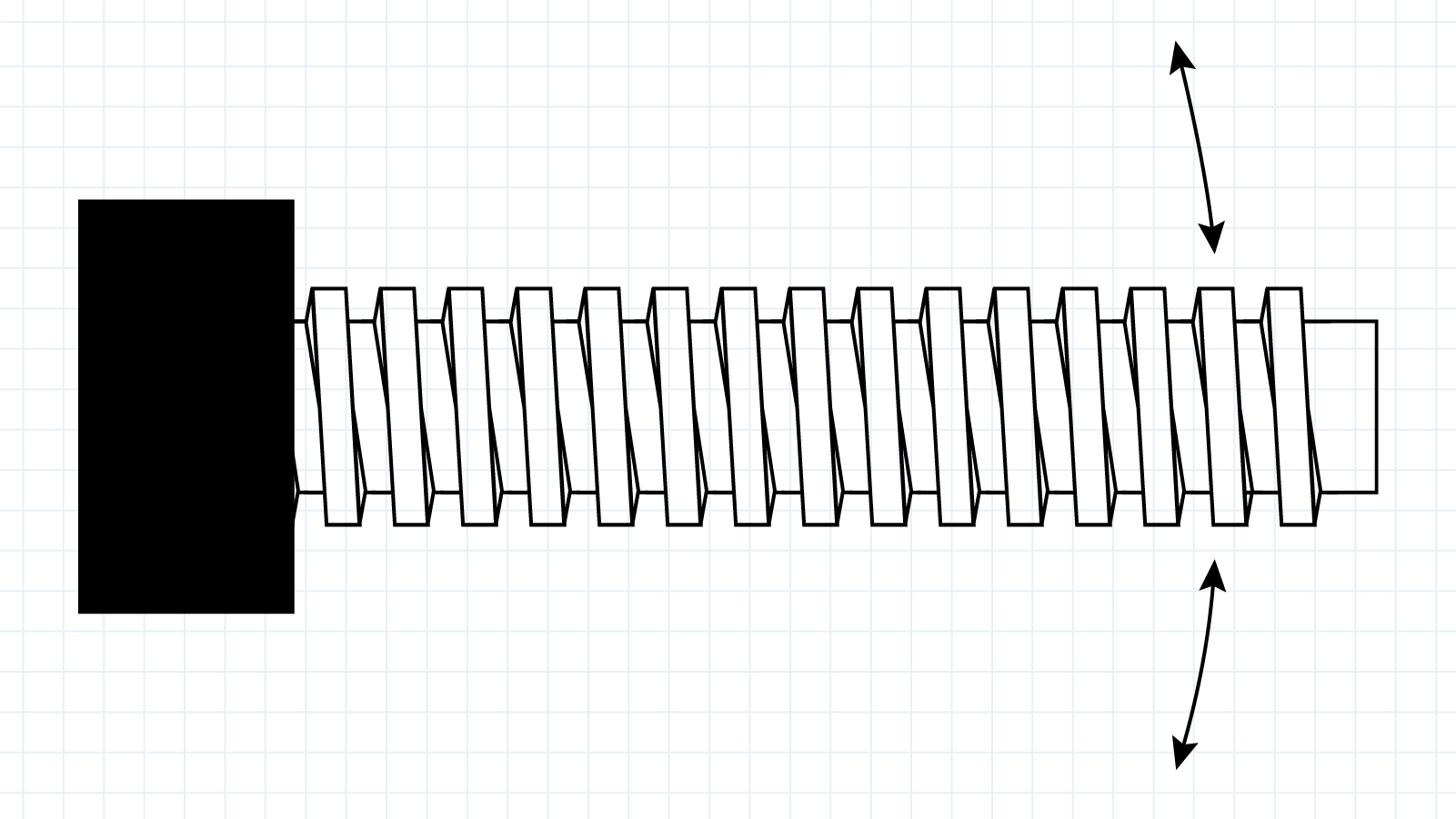

Fixed/Free: One end is supported with a double bearing, and the other is free.

NOTE: Not recommended for any application other than short travels and slow speeds.

Simple/Simple: Both ends are supported with a single bearing.

Fixed/Simple: One end is supported with a double bearing, and the other is backed with a single bearing.

NOTE: When supporting both ends of a screw with double bearings, the screw is highly ridged, and extra care should be taken to ensure compliance in the assembly design.

CAUTION: When using fixed bearing mounts on both ends, contact a Helix Engineer to determine the mount-to-mount length tolerance of the final assembly.

As we discussed in the beginning, the type of acme screw that you'll need depends upon a variety of different variables, including load, speed, length, and end fixity. All of these variables are somewhat related to the other. For instance, in the example given above, where we depicted an assembly with one end mounted and one end free, this assembly's potential speed and length are directly related to the use of this mounting style. Choosing this option would only accommodate an application with minimal travel distance and slow travel speed. It's important to consider all of the variables within any application and to consult with the experts before deciding on mounting options if needed. Failure to do so could result in a lead screw assembly that doesn't stack up - and that is an issue that you surely don't want to encounter.

As always, feel free to contact Helix with any questions.