How Stepper Motor Linear Actuators Help Increase Efficiency

Linear actuators are mechanical devices used to generate motion in a straight line.

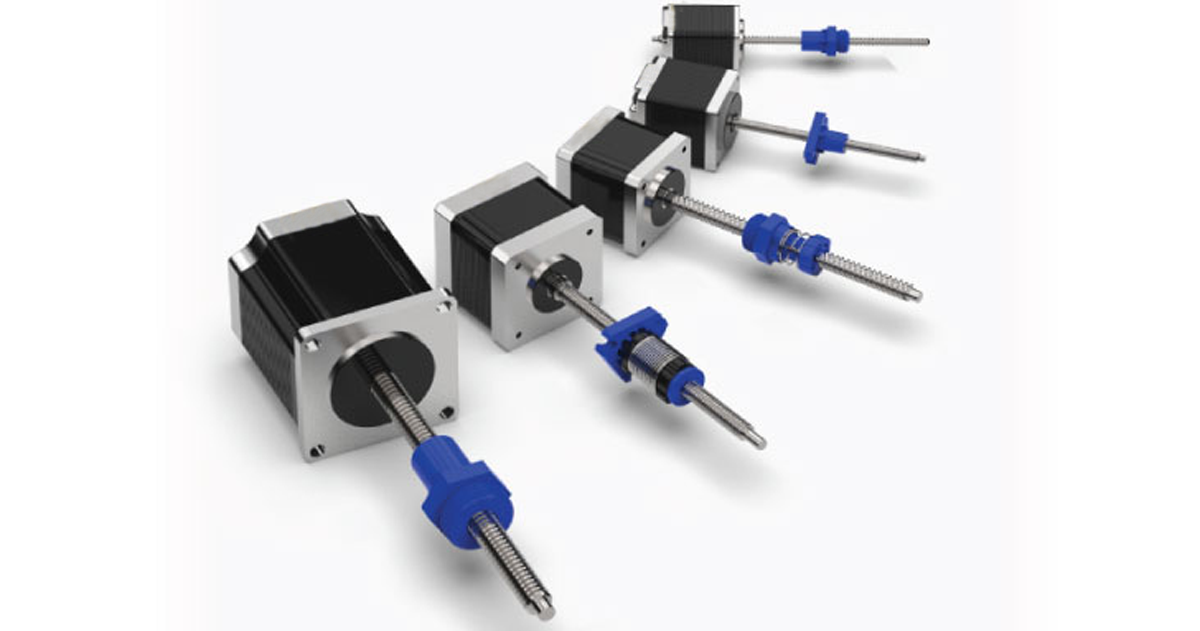

Linear actuators can be lead screw, ball screw or roller screw driven and are used in various industries and applications to convert rotary motion to linear motion. A precision ball nut or lead screw nut fits inside the motor's rotor in a linear actuator, and a lead screw replaces the shaft. The rotor turns, creating high-resolution linear motion with the nut and threaded lead screw combination. The addition of encoders for closing the loop on position and zero or anti-backlash nuts improves accuracy and repeatability in lead screw-driven linear motion systems.

Stepper motors are commonly used as a rotary power source to drive linear actuators due to ease of speed control, high accuracy, and reliability. Depending on the motor size, available voltages range from 2.1V to 12V. Low voltage motors generally have a higher current, offering the potential for more power or force. A higher voltage linear actuator 12V motor can be more suited for battery-powered devices because it draws less current and can extend battery life.

Although many applications will use 24V, 48V, and 60V power supplies, some use 12V power supplies for driving linear actuators. When sizing a power supply for the driver, general operating parameters require input voltage to be eight times the motor's operating voltage. For example, when using a 5V motor, a power supply voltage of 40V or greater should be used, helping optimize the motor's operating parameters.

Another operational guideline to consider when selecting a stepper motor linear actuator is that the actuator can run at 2x the rated current, as long as the duty cycle is low (typically 25%) to ensure the motor doesn't overheat. The increase in current can boost the actuator during acceleration, overcoming drag or friction in the system, or screw inertia to get the shaft from a stopped position to peak RPMs (especially on longer stroke lengths and larger diameter lead screws).

When inertia and weight are vital issues, using hollow lead screws or aluminum lead screws to reduce weight can solve application problems. Stage lighting and aircraft seating are typical applications that use alternative lead screw materials. When both lightweight materials and strength are required, titanium lead screws are ideal. In many cases, titanium lead screws can be manufactured with the existing rolling dies.

Whatever linear actuator is used, the proper drive selection contributes to obtaining the desired speeds, force, and accuracy. These highly-reliable motors are used in many applications, including surgical robotics, laboratory testing machines, imaging equipment, fluid control, valve control, 3D printing, X-Y tables, and pick-and-place automation. With industry-increasing industry trends in miniaturization, cost reduction, and high degrees of control, the use of stepper motor linear actuators will continue to expand and meet these needs.