Optimizing Precision and Efficiency with Ball Screw Linear Actuators

A Mechanical Engineer's Guide

As mechanical engineers, we are constantly seeking innovative solutions to enhance precision and efficiency in various applications. One such remarkable invention that has revolutionized linear motion systems is the ball screw linear actuator. In this blog post, we will delve into the intricacies of ball screw linear actuators, exploring their functionality, advantages, applications, and key factors to consider during selection and optimization. Join us on this journey of unlocking the potential of ball screw linear actuators for cutting-edge engineering projects.

Understanding Ball Screw Linear Actuators

What is a Ball Screw Linear Actuator?

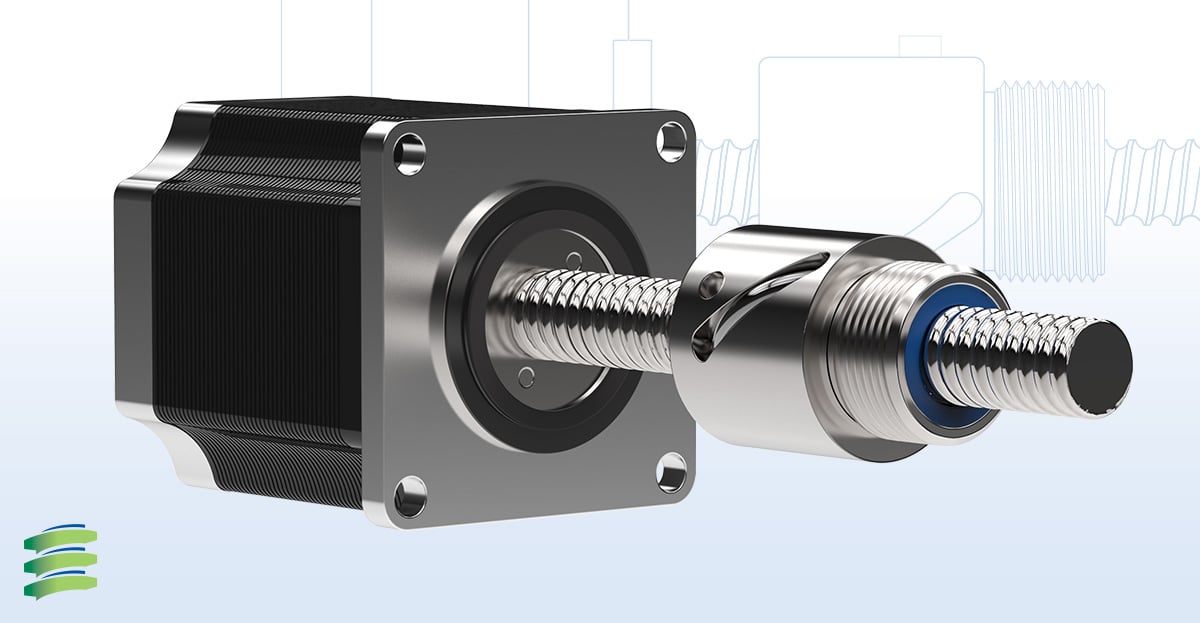

A ball screw linear actuator is a mechanical device designed to convert rotary motion into linear motion, offering precise and controlled movement in a linear direction. It consists of a screw mechanism with a series of ball bearings circulating within the nut and screw assembly. The balls reduce friction, resulting in efficient and accurate linear motion. Download our Ball Screw Linear Actuator Catalog HERE.

How Do Ball Screw Linear Actuators Work?

At the heart of a ball screw linear actuator is a threaded shaft, or screw, and a nut with corresponding grooves. As the motor drives the screw, the balls rotate within the grooves, simultaneously pushing and pulling the nut along the screw's length. This rotation-to-linear motion conversion provides high efficiency and exceptional accuracy in a wide range of applications.

Advantages of Ball Screw Linear Actuators

High Precision and Repeatability

Ball screw linear actuators offer exceptional precision and repeatability, making them ideal for applications requiring precise positioning or controlled movement. The ball bearings reduce friction and play a vital role in minimizing backlash, ensuring accurate and reliable motion.

Efficient Power Transmission

Compared to other linear actuation methods, ball screw linear actuators excel in power transmission efficiency. The rolling contact between the balls and the screw threads enables high load-carrying capacity while minimizing energy losses due to friction.

Smooth and Quiet Operation

Thanks to the rolling motion of the balls within the nut and screw assembly, ball screw linear actuators provide smooth and quiet operation, making them suitable for applications where noise reduction is crucial.

Compact Design and High-Speed Capability

Ball screw linear actuators offer a compact design, enabling their integration into space-constrained systems. Additionally, they can achieve high travel speeds, facilitating rapid and efficient motion in dynamic applications.

Applications of Ball Screw Linear Actuators

Robotics and Automation

Ball screw linear actuators find extensive use in robotics and automation systems. Their precise and repeatable motion control capabilities enable robots to perform intricate tasks, such as pick-and-place operations, assembly, and material handling.

CNC Machinery

In computer numerical control (CNC) machinery, ball screw linear actuators are pivotal components for precise tool positioning and workpiece movement. Their high accuracy and rigidity contribute to superior machining performance and surface finish.

Medical and Biotechnology Equipment

Ball screw linear actuators play a crucial role in medical and biotechnology equipment, where precise and controlled motion is paramount. They are employed in applications such as laboratory automation, diagnostic devices, and medical imaging systems.

Aerospace and Defense

In the aerospace and defense industries, ball screw linear actuators are utilized in aircraft control surfaces, missile systems, and satellite mechanisms. Their reliability, compactness, and ability to operate in harsh environments make them suitable for demanding applications.

Factors to Consider for Optimization

Load Capacity and Speed Requirements

When selecting a ball screw linear actuator, it is crucial to consider the load capacity and speed requirements of your application. Determining the maximum load and desired travel speed will ensure optimal actuator selection and system performance.

Accuracy and Backlash

For applications demanding high precision and repeatability, evaluating the actuator's accuracy and backlash characteristics is essential. Lower backlash and higher accuracy specifications contribute to improved performance and positioning control.

Environmental Considerations

Operating conditions, such as temperature, humidity, and exposure to contaminants, must be considered when optimizing ball screw linear actuators. Selecting appropriate seals, lubrication, and protective coatings will enhance durability and reliability in challenging environments.

Conclusion

In the realm of mechanical engineering, the ball screw linear actuator stands as a powerful and versatile tool, enabling precise, efficient, and reliable linear motion. By understanding their working principles, advantages, and applications, engineers can harness the potential of ball screw linear actuators to optimize various systems. With careful consideration of factors such as load capacity, speed requirements, accuracy, and environmental conditions, engineers can ensure the selection and optimization of the ideal ball screw linear actuator for their specific projects. So, embrace the power of ball screw linear actuators and unlock new possibilities in precision engineering.