Advancements in Precision for Anti-backlash, Axial, and More Nut Types

Exploring the Features and Benefits of Axial, Radial, and Torsional Anti-Backlash Nuts

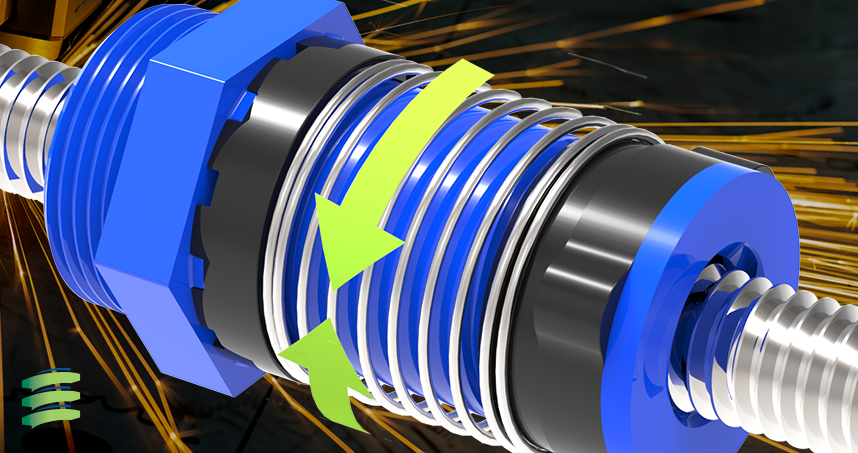

In the world of mechanical engineering, precision, and accuracy are paramount. Designing systems that eliminate unwanted motion, such as backlash, is crucial to ensure optimal performance and reliability. One innovative solution that addresses this challenge is the anti-backlash lead screw nut. In this blog post, we will delve into the features and benefits of three types of anti-backlash nuts: axial, radial, and torsional. By understanding their unique characteristics, engineers can select the most suitable anti-backlash nut for their applications, enhancing precision and efficiency.

Axial Anti-Backlash Nut:

The axial anti-backlash nut is specifically designed to counteract linear motion backlash in a linear actuator or lead screw assembly. It incorporates features such as preloaded springs, adjustable screws, or split-nut designs to eliminate any free axial movement between the nut and screw. This configuration minimizes backlash and ensures precise positioning, particularly in applications where accuracy and repeatability are critical.

Benefits

- Enhanced Precision: By eliminating axial backlash, the axial anti-backlash nut ensures accurate linear motion, contributing to improved positioning and overall system precision.

- Repeatability: The removal of backlash translates to consistent positioning, enabling repeated movements without any loss of accuracy.

- Increased Efficiency: With reduced backlash, less energy is wasted in compensating for backlash errors, resulting in improved overall system efficiency.

- Longevity: The elimination of axial backlash reduces wear and tear on the system components, leading to longer service life and decreased maintenance requirements.

Radial Anti-Backlash Nut:

The radial anti-backlash nut is employed in rotary motion systems to mitigate backlash along the rotational axis. It employs mechanisms such as spring-loaded pistons, eccentric mechanisms, or adjustable split-nut designs to minimize play between the nut and the rotating shaft. This solution is used in applications like rotary tables, robotics, and CNC machines.

Benefits

- Accurate Rotary Motion: The radial anti-backlash nut ensures precise rotation without any lost motion, enhancing the accuracy and repeatability of rotary systems.

- Smooth Operation: By reducing backlash, the nut minimizes jerky or erratic movements, providing smoother operation and minimizing vibrations, thus enhancing system performance.

- Improved System Lifespan: The reduced backlash leads to less wear and tear on the components, thereby extending the lifespan of the rotary motion system and reducing the need for frequent maintenance.

- Increased Efficiency: The elimination of backlash results in more efficient power transmission, optimizing energy usage and reducing losses.

Torsional Anti-Backlash Nut

The torsional anti-backlash nut is specifically designed to mitigate backlash in systems that involve rotational motion combined with linear actuation. It utilizes spring-loaded mechanisms or adjustable split-nut designs to eliminate rotational backlash, ensuring precise motion control in applications like robotic arms, linear stages, and automation equipment.

Benefits

- Enhanced Motion Control: The torsional anti-backlash nut eliminates unwanted rotational play, facilitating precise coordination of linear and rotational motions, thereby improving the control and accuracy of the system.

- Reduced Oscillations: By minimizing backlash, the nut reduces oscillations and vibrations during rapid changes in direction, resulting in smoother and more stable operation.

- Increased System Reliability: With the elimination of backlash, the torsional anti-backlash nut enhances the reliability of the system by minimizing the risk of position errors or mechanical failures.

- Flexibility: Torsional anti-backlash nuts often offer adjustability features, allowing engineers to fine-tune the nut's performance to suit specific application requirements.

Conclusion

In the quest for precision and accuracy, the choice of the appropriate anti-backlash nut is crucial. Axial, radial, and torsional anti-backlash nuts offer unique solutions to mitigate backlash in linear, rotary, and combined motion systems. By employing these innovative mechanisms, engineers can achieve enhanced positioning accuracy, improved repeatability, increased system efficiency, and extended component lifespan. The selection of the right anti-backlash nut can significantly contribute to the success of various applications in industries ranging from manufacturing to robotics and automation, paving the way for enhanced performance and reliability in the field of mechanical engineering.