The Top Five Benefits of Using an Electric Linear Actuator in Projects

When it comes to linear actuators for motion-control applications, there are several types to choose from. These include pneumatic, hydraulic, electric, or electro-mechanical. While the hydraulic and pneumatic technologies are perhaps the most popular linear actuators, electro-mechanical linear actuators are gaining traction due to their benefits compared to the competition. Electro-mecahanical solutions are becoming a preferred solution for the medical device, packaging and the defense industries,

With that being said, here's a look at the top 5 benefits of using an electric linear actuator and why more engineers are trending toward this type of technology.

1. Low Maintenance

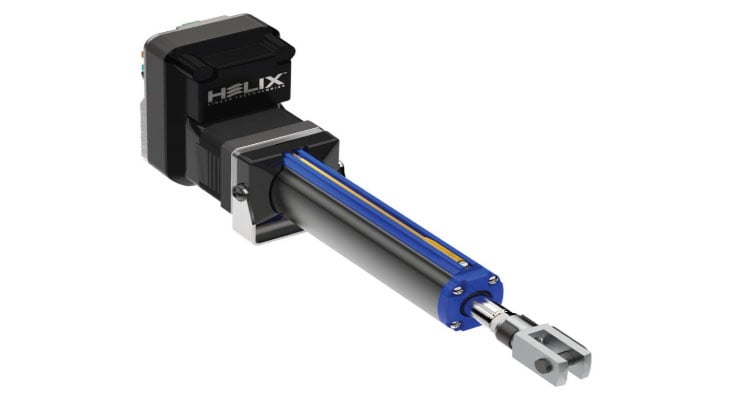

Electro-mechanical linear actuators have advanced to the point where they are just about maintenance-free. They are much less complex than their pneumatic and hydraulic counterparts, typically a motor, gearbox, ball screw, and clutch, making them easier to maintain. They often require little to no lubrication.

The fluid must be checked and added or changed regularly to ensure proper operation and prevent contamination with hydraulic systems. What's more, multiple axes may be controlled by a single hydraulic system, so a seemingly small problem can potentially impact many parts of the operation. Electric actuators are also easier to troubleshoot for numerous reasons.

2. Low Cost

Low maintenance translates to a lower cost of ownership. There are two main factors to consider when it comes to cost. A general rule of thumb is that if you have a hydraulic system operating one, two, or three axes, it can be replaced with an electro-mechanical equivalent for less money. The second factor is that compared to hydraulic-based linear motion systems, electric actuators cost less to operate. This is primarily because they only require power when they're moving. Pneumatic systems require air even when motion isn't needed, essentially wasting energy. Hence, it's estimated that using an electric actuator can offer cost savings of up to 90 percent.

It's a popular misconception that electric actuators cost more than competitive technologies. That's not true anymore, and the savings accrued over their lifetime make them an economic investment.

3. Safety

Hydraulic and pneumatic actuators are prone to leaks and ruptures where electro-mechanical systems are not. This is a health and safety concern - not to mention the potential sizeable repair costs generally associated with those technologies. Electric actuators don't have these problems.

4. Eco-Friendly

Unlike pneumatics and hydraulics, electric linear actuators run on electricity, a clean technology. Due to the technology's low risk of product contamination is preferred in various industries, such as the pharmaceutical, food, water, and medical industries. The increased efficiency and clean technology benefits help to reduce an organization's environmental footprint.

Electric actuators also run much quieter than hydraulics and pneumatics providing a safer and more pleasant working environment. Health and safety guidelines state that machines should operate at a maximum of 85 decibels at 1 meter, which this technology easily meets.

5. Less Complex Design

This final benefit is perhaps the most important. Electric linear actuators have an uncomplicated design, making them easier to integrate into a variety of applications. In addition to this, the technology is also easily integrated with other systems and equipment. The decreased design complexity of electric linear actuators allows your design to be more complex - and that's a significant benefit.