Maintaining Syringe Pump Precision at Lower Cost with Lead Screws!

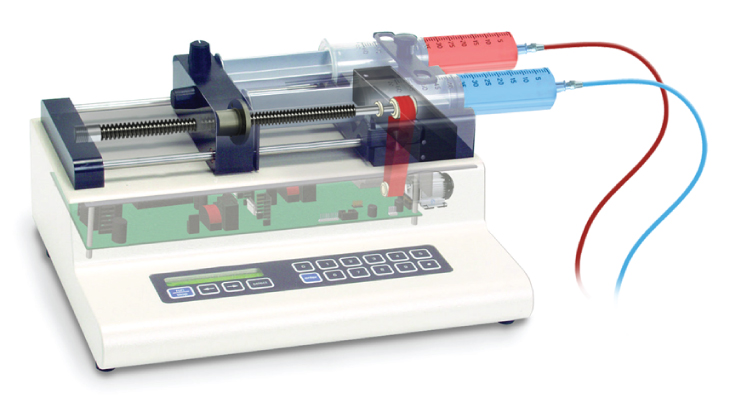

Syringe pumps for medical treatment and chemical/biomedical research have substantially increased in recent years. The most common application for these small infusion pumps is to gradually administer intravenous medications to patients, including pain-killing analgesics, nausea-suppressing anti-emetics, and other drugs. Syringe pumps are also used to control the administration of small amounts of fluids as part of laboratory research.

The Challenge: Maintaining Precise Syringe Pump Operation Control

Syringe pump manufacturers face the challenge of maintaining precise pump operation control so that exact volumes of fluids and medications are dispensed while making the pumps more cost-effective to produce and more compact, quiet, and maintenance-free to deploy. Traditionally, syringe pump manufacturers have utilized ball screws to maintain precise control of the linear actuation of the pump plunger. However, the disadvantages of relying on ball screws for this application are that they increase syringe pump costs, tend to be bulky, and often require lubrication, which is problematic in medical and laboratory settings.

The Solution: Precision Lead Screws

A new generation of precision lead screws and highly engineered plastic nuts are now available for syringe pump applications. Precision lead screws not only offer the same high degree of linear actuation precision afforded by ball screws, but they also provide a more customizable solution for syringe pump design and are available at a fraction of the cost of ball screws.

In addition to providing a more cost-effective precision linear actuation solution, a precision lead screw is smaller and offers the mandatory lubricant-free operation in clean environments.

Precision lead and acme screws are less bulky than ball screws and fit the compact design profile required for syringe pump development. These screws are available in 4-millimeter to 25.4-millimeter diameters. A lead screw is smaller than a comparable ball screw and offers syringe pump designers the opportunity to utilize stepper motors with more compact footprints.

The need for liquid lubricants for precision lead screws is eliminated by combining a Teflon® coating on the screw with a custom-engineered nut available in bronze or plastic.

Using custom-designed, injection-molded nuts on its precision lead screws enables syringe pump manufacturers to use custom screw assemblies, thereby reducing parts from their bills of materials (BOMs). Fewer parts result in manufacturing, assembly, and maintenance cost reductions. Syringe Manufacturers can also utilize customized thread profiles and pre-loaded anti-backlash nuts to facilitate syringe pump design innovation.

The Helix Linear Technologies Advantage

Helix Linear Technologies offers the broadest product line of any lead screw manufacturer, including a full line of rolled, milled, or ground screws and nuts in standard and customizable sizes. The company provides the flexibility required to service the expanding and evolving customer-driven market for precision linear motion products.

Whether you need Acme, Trapezoidal, or Speedy® (high lead) threads with a precision anti-backlash nut, or a state-of-the-art anti-backlash design, it delivers the highest quality products of exceptional value to its customers.

This 4-page case study includes more information about how lead screws help maintain syringe pump precision and more detailed application cut-aways.