Why Acme Screws Are Ideal for Heavy-Duty Industrial Applications

Key Benefits of Acme Screws in Heavy-Duty Applications

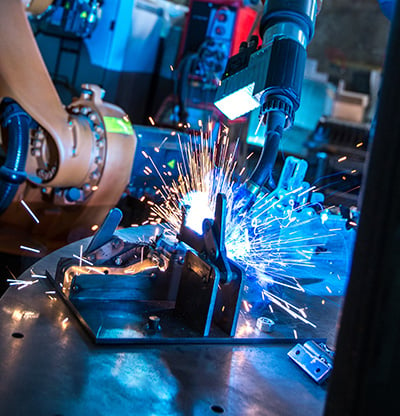

When it comes to heavy-duty applications, choosing the right components is important to ensure efficiency, safety and durability. Thanks to their trapezoidal thread design and robust construction, lead screws are great for demanding environments. Their ability to handle high loads, resist wear and provide smooth, reliable motion makes them an excellent choice for industries that operate under extreme conditions.

High load capacity

One of the key advantages of Acme screws is their ability to handle heavy loads with ease. This strength is primarily due to their trapezoidal thread design, which allows for an even distribution of force across the threads. The wider surface area provided by the trapezoidal profile enables Acme screws to bear significantly more weight than other types of screws, making them an ideal solution for applications where lifting or supporting heavy loads is routine.

Durability in harsh environments

Durability is paramount in any heavy-duty application. It is also essential in environments where equipment is exposed to dust, debris, moisture, or high levels of vibration. In these conditions, components are often subjected to constant stress, and weak or poorly made parts can lead to breakdowns or equipment failure.

Acme screws can withstand the harsh conditions typically found in a wide range of industries. Their ability to resist environmental damage and maintain their integrity over time means fewer replacements and less downtime; this ensures cost savings and increased operational efficiency.

Smooth and controlled motion

Beyond their strength and durability, acme screws also offer controlled motion, which is essential in applications where precision is required. The design of the threads allows for consistent, linear movement, even under heavy loads. This makes acme screws particularly useful in applications where precise, repeatable motion.

A key feature of Acme screws is their self-locking capability. This means that when subjected to a load, the screw will not back drive unless a significant external force is enforced. This self-locking feature is particularly valuable in applications where maintaining position under load is necessary.

Low maintenance and long service life

Another major benefit of Acme screws is their low maintenance requirements and long service life. The robust construction of Acme screws, combined with their self-locking feature, results in less wear and tear on the system overall. Because Acme screws can maintain position under load without requiring additional mechanical components like brakes, there is less stress on both the screw and the system as a whole. This translates into fewer maintenance checks and a longer lifespan for the screw and the equipment it supports.

Acme screws also mean they can continue to operate effectively over extended periods, including in environments with high levels of debris or exposure to the elements. They also help to reduce long-term operational costs and downtime due to their tendency to be reliable for years with minimal maintenance.

Conclusion

Acme screws offer a combination of high load capacity, durability, precise control, and low maintenance that makes them an ideal solution for heavy-duty applications. Whether in construction, manufacturing, agriculture or aerospace, industries that rely on robust, long-lasting components benefit greatly from the unique properties of Acme screws. Their ability to perform reliably under heavy loads and in harsh conditions ensures that they will continue to be a go-to option for companies seeking cost-effective, durable solutions for their most demanding applications.