The Advantages and Four Most Common Uses of Electric Linear Actuators

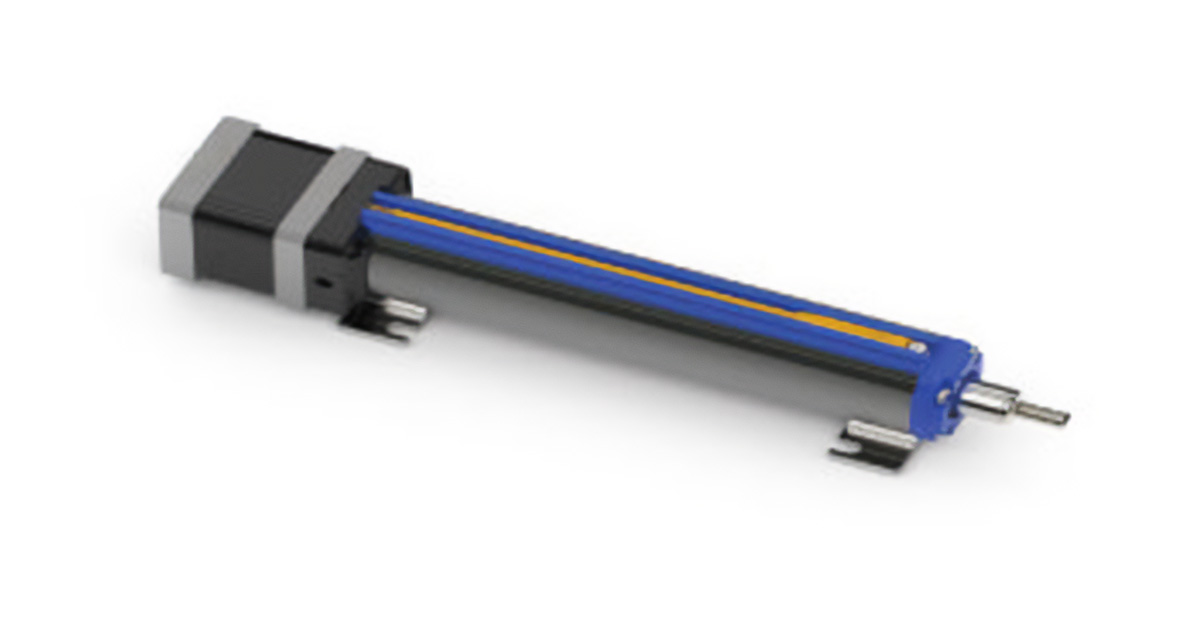

Electric linear actuators convert rotary motion into linear motion by rotating a lead screw, ball screw or roller screw. Although several different forms of energy such as electrical, pneumatic, hydraulic, mechanical, and piezoelectric can be used as a source to drive an electric linear actuator, using AC or DC power to run an electric motor is by far the most predominant.

The advantages of electric linear actuators

- Electrical current is quickly routed to actuators because cabling is more accessible and less costly than piping

- Energy is delivered to the motor cleanly and quietly

- Electricity is efficient and cost-effective

- Control of the power source is easy

- Electrical faults are usually easier to troubleshoot

- Electric linear actuators provide precise control of acceleration, speed, position, and/or torque

- They can position the load at variable and repeatable locations within the full stroke

- They can synchronize multiple axes for coordinated moves

- They can be reprogrammed or reconfigured to handle multiple applications

- These actuators can be synchronized with other machine operations

With so many advantages to offer, it's no wonder that these linear actuators are the most widely used form of a linear motion control system. Their potential application options can be characterized through an understanding of their four primary uses.

1. Repeated Linear Movement

Electric actuators are often the solution of choice for repeatedly moving a load—or several loads—to a consistent location—or locations—in a continuous fashion. Repeated linear movement sometimes requires synchronizing multiple axes to facilitate coordinated moves. If you need to repeat the motion and continuously coordinate several different motions, this type of actuator is often the best solution.

2. Adaptable Movement

Linear motion that changes or adapts—frequently referred to as adaptable movement— is another critical application. Whenever load, positions, or the very nature of the motion itself changes—as often is necessary for synchronizing movements with other machine operations—you can use these actuators to control and facilitate adaptable movement.

3. Controlled Precision Movement

Precisely controlled motion—the accuracy of which is beyond the capabilities of an actual person without exhibiting human error—is another important electric actuator use. With these linear actuators, you can control position with extreme levels of precision, duplicate and repeat precise movements within the whole stroke, and even reprogram or reconfigure specific motions to support multiple applications.

4. Acceleration Controlled Movement

Electric linear actuators are also used to control the rate of acceleration. Because you can precisely control speed, position, and torque, you can make the actuator accelerate or decelerate as quickly and as often as you need.

Helix Can Help You Understand Your Linear Actuator Requirements

Before selecting an actuator, consult with HELIX Linear Technologies to identify your specific application's optimal motion control system. Helix engineering specialists can help you assess your motion control needs and configure an actuator that meets the requirements of your situation and adds value to your overall product design.