Acme Screws Pave the Way for Affordable Design in Linear Motion

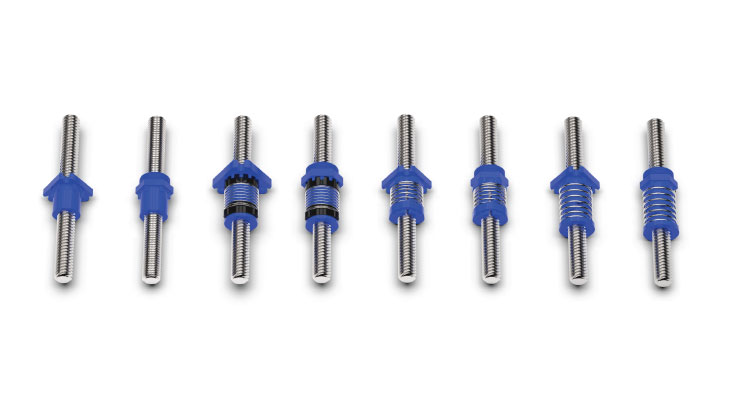

Acme screws and nuts convert rotary motion into linear motion by turning either the screw or the nut. There are several reasons why acme screws quickly become the norm for design engineers in linear motion applications involving everything from medical products to electronics. Acme screws and nuts can easily be tailored to your specific application, are low maintenance (they require less lubrication than alternative options), resist corrosion better than competing technologies, and operate quietly.

Those are just some of the benefits of choosing an acme lead screw over competing linear motion products. There is another significant benefit that you can't underestimate when it comes to product development: cost. Acme screws and acme screw assemblies are often the most affordable option for many precision linear motion applications.

How affordable? It's estimated that choosing an acme lead screw for your design can cut costs by up to 85 percent over alternative options such as a ball screw. Considering that an acme screw's accuracy approaches that of a ball screw, operates more quietly, requires less maintenance, and costs much less, why wouldn't you choose an acme lead screw? Especially considering that you can achieve the performance, you need at a much lower cost.

Here's a closer look at some of the ways that acme lead screws can help reduce cost, thereby leading to more affordable product design:

More minor moving parts: Acme lead screws have far fewer moving parts than competing technologies, which is a huge factor in cost savings. Acme screws contain no moving parts. The simplicity of their design not only helps to reduce cost but also helps applications to run quieter. In contrast, the moving parts in a ball screw assembly and other competing technologies produce unwanted noise and require exact tolerances, making them intolerant of contaminants.

Low maintenance: Not only do acme screws cost less initially, but their low maintenance also translates into cost savings over your product's lifetime. Helix acme lead nuts are designed with a proprietary self-lubricating thermoplastic that requires little to no lubrication and virtually no maintenance. Helix acme screw assemblies are preferred in applications where maintenance is difficult or impossible - like infusion pumps. To further reduce friction and increase life, Helix lead screws can also be coated with PTFE, a material with a very low coefficient of friction.

Production: Helix screws are produced quickly and efficiently using a thread rolling process that is more affordable than machining or grinding. The rolling process is much faster and more efficient than other methods. Still, it maintains an impressive lead accuracy of .0003"/in (higher accuracy available upon request), suitable for most applications where precision is a must.

Having to "design around" a particular component rather than designing for the optimal function of the product is often a designer's worst nightmare. With Helix lead screws and assemblies, designers will never have to confront this problem again. Helix produces lead screws precisely to our customer's specifications so that they can be easily integrated into the envelope of the application and not the other way around. We offer standard screw end machining suitable for most applications, and we also provide custom end machining. Likewise, we can machine and/or injection mold custom nuts and modify off-the-shelf designs to accommodate whatever level of customization your application demands.

It's easy to see why Helix lead screws are the preferred choice in product development, no matter what industry. Not only are Helix screws and assemblies high-quality products that stand up to the test of time, but they can also shave cost from your design, resulting in savings to your bottom line as well as to your customer.