The Importance of Acme Screws for Linear Motion Innovation

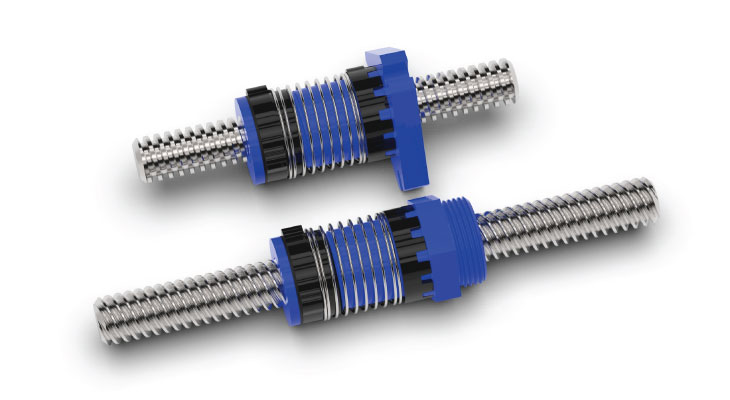

Lead screw assemblies convert rotary motion into linear motion by turning the lead screw or the lead screw nut. One of the most popular types of lead screws uses the Acme thread form, which typically has an included thread angle of 29°. This produces solid and efficient threads, which has helped establish them as the best option for many motion control applications that we see today. Acme screws are simple and effective and rely on sliding friction between the lead screw nut and the lead screw. Acme screws have a much lower replacement cost than other screw systems, such as ball screw and planetary roller screws.

So why are Helix Linear Acme screws a significant driver of linear motion innovation? It's all part of their makeup. We use a proprietary custom-blended thermoplastic material integrated with friction fighting PTFE. We can also apply PTFE coating to our lead screws to further reduce friction. Ball screws and roller or "planetary" screws have their place but are often overkill and overpriced for many applications. A case-in-point example of these benefits and their driving innovation is their increased use within medical applications such as a syringe pump.

Affordability

Acme screws are significantly less expensive than complicated roller screws or ball screws in terms of initial cost and ongoing maintenance. Acme screws have fewer moving parts, which translates into a lower price. When combined with the customization costs for your particular application, cost savings could be as high as 85 percent compared to competing screw types. That's a significant saving, and more and more OEMs are starting to reap the benefit. In specific clean applications, Acme screws can be run without lubrication. No lubrication to re-apply means no maintenance to worry about and, therefore, lower maintenance costs.

Reliability

Every engineer knows that more moving parts mean more chances for failure. Helix Acme screws owe their reliability to their simplicity. This simplicity of the design also directly translates to quieter operation and less vibration. Lead screws are more tolerant of contaminants than ball screws. Ball screws have complicated ball return tubes, and when dirt gets into the balls and raceways, they no longer have smooth travel, and their life is reduced. Roller or "planetary" screws have expensive gears that must be precisely aligned, all of which significantly increase their cost.

The life of an Acme screw does depend on the application. Many factors such as load, speed, duty cycle, nut material, cleanliness, and screw coating affect useful life. Contact Helix Linear Technologies engineering department for assistance with your application. We will use our expertise and experience to optimize your solution.

Customization

Acme screws can be custom manufactured for any application, from microscopes to cutting machines. Helix Linear Technologies manufactures precision Acme screws and trapezoidal screws via thread rolling, thread milling or thread grinding with standard inch diameter sizes that range from 1/8" to 6," and metric diameter sizes that range from 4mm to 65mm. Based on this manufacturing flexibility, designers and engineers can make the screw fit the design rather than make the design fit the screw. This is a significant driver of innovation because, with the hundreds of different configurations available, Acme lead screws can be included in virtually any design envelope without sacrificing other design considerations in the product development process. And by the way, our screws are not the only thing that can be customized. Many of our standard nuts can also be modified to suit your particular application. Our engineering team can work with you to provide a custom solution – thereby providing greater design flexibility.

Affordability, Reliability, and Customization

These three characteristics can all be used to describe Helix precision lead screws, and they are three primary reasons Acme screws are instrumental in driving linear motion innovation.