In-House Die Grinding from Concept to Production!

At Helix Linear Technologies, all of our thread-rolling dies are made right here in our facility located in Cleveland, Ohio. What does this mean for you? When you order a custom lead screw, this in-house capability allows us to take your project from concept to production in less time.

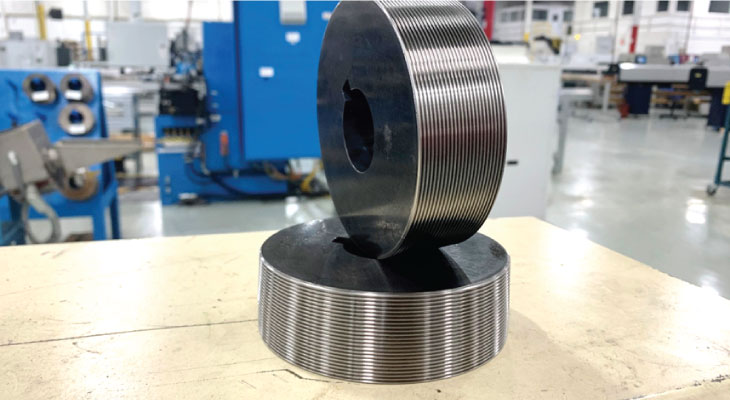

Thread rolling is the process of forming screw threads by rolling material through dies. There are many different thread forms including v-thread, square thread, metric thread, and acme thread. Even though thread rolling is the best way to manufacture precision lead screws, it also has plenty of benefits as well.

Some benefits of thread rolling include:

- Lower production times

- Lower cost because of efficient use of materials

- Lower coefficient of friction

- Precise threads

- Excellent surface finishes

If you have an existing lead screw or nut, we can supply replacements and additional components. Our advanced technology and manufacturing processes allow us to scan and replicate your existing part with industry-leading accuracy. Plus, our capabilities don’t stop there. We offer custom machined end options, specialty coatings, custom nuts, and full end-to-end linear motion project solutions. There isn't a linear motion project our engineering team can't tackle.

Helix Linear Technologies is a global manufacturer and supplier in the medical device, life science, security, semiconductor, aerospace, electro-mechanical, and defense industries. A leader in linear motion, we produce the world's highest quality linear actuation solutions. We focus entirely on electro-mechanical actuation systems, designed to help our customers be more productive and profitable. Our innovative product design engineers solve real problems for our customers, helping them build a foundation for long-term success.

For more information on thread rolling or help with your linear motion needs, contact Helix Linear Technologies today!