Five Steps for Selecting Lead Screw

Selecting the right motion control system can often mean the difference between success and failure. To optimize performance, reliability, maintenance requirements, and service life, design engineers should conduct a thorough evaluation of their options in conjunction with configuring the most suitable lead screw as a means to drive the specific application.

It would be best to consider critical motion control factors that influence linear motion performance before selecting or designing a motion control system. Here are five things to consider during evaluation.

1.) Lead Screw Characteristics

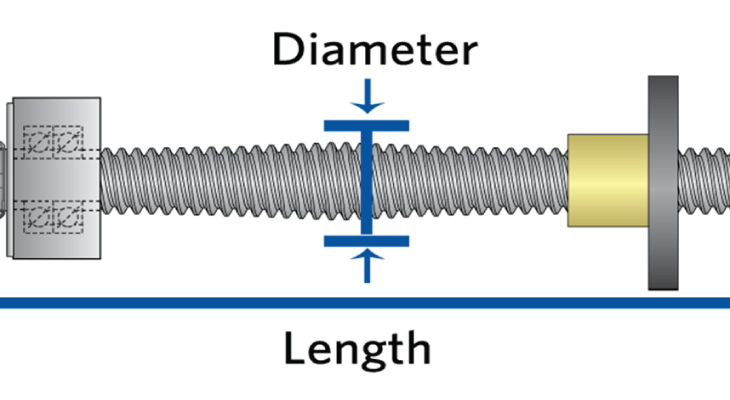

The first question to ask yourself is how large does the lead screw need to be? This will vary from application to application, but key size considerations include the diameter and length of the lead screw and the lead screw's load capacity. You certainly don't want to oversize or undersized your motion control system, so understanding space and load constraints as they apply to lead screw size represent the first step toward identifying the right motion control system.

2.) Precision, Timing, and Back Driving

The next important consideration is to assess the precision, timing, and reversibility requirements of your application. Select the best lead—the linear distance the screw travels in one revolution— for the load and timing of your application. Make sure to choose a lead that produces sufficient friction to maintain linear motion without slipping under load.

What pitch does your application warrant? Like the lead, the pitch—the distance between a point on one thread and a corresponding point on the following thread parallel to the axis—carries ramifications based on load, travel distance, and timing.

What amount of motor torque is required to drive your system? To evaluate motor torque requirements, you'll need to consider inertial torque, drag torque, and torque-to-move, the last of which is the torque required to drive just the screw assembly. Additional torque to be considered includes driving frictional bearings, motor shafts, other moving components, and drag related to general assembly misalignment. You'll also need to assess the back driving torque required to reverse and return the system to its original position.

3.) Power Control Options

What type of power source do you need to drive your system? Should you use a motor powered by AC or DC or configure your system for both to accommodate power outages? What kind of control signal is required? Some motion control systems may require a highly accurate control signal, such as that provided by the Nook Sensor System™, which features repeatability up to ± .004" (0.1mm).

4.) Cost Factors

Anticipating cost factors and evaluating the cost/benefit of your motion control system is critically important to maintaining a lean, well-functioning system. Investigate overall costs related to your system to maximize your cost/benefit ratio.

5.) Diagnostics, Maintenance, and IT

The last critical step for selecting a motion control system is to evaluate the availability of diagnostics for maintaining and troubleshooting the system, assessing overall maintenance requirements, and projecting the involvement of IT support. In other words, who will own the IP (intellectual property) of your motion control system? If your company will, then diagnostics, maintenance, and service will be the responsibility of your IT department or make sure that your motion control vendor provides a suitable alternative solution.

You can also use our Lead Screw Calculators to help size your lead screw.