Precision Motion Systems: The Application of Ball Screws

The quest for accuracy and repeatability is unending in engineering and precision control. Whether it's a CNC machine tool, a medical device, or 3D Printer, achieving precise motion control is essential. One key component that has revolutionized the realm of precision motion systems is the ball screw assembly. In this blog post, we will explore the application of ball screws in precision motion systems, uncovering the science behind their operation, their advantages, and where they shine in various engineering applications.

Understanding the Ball Screw

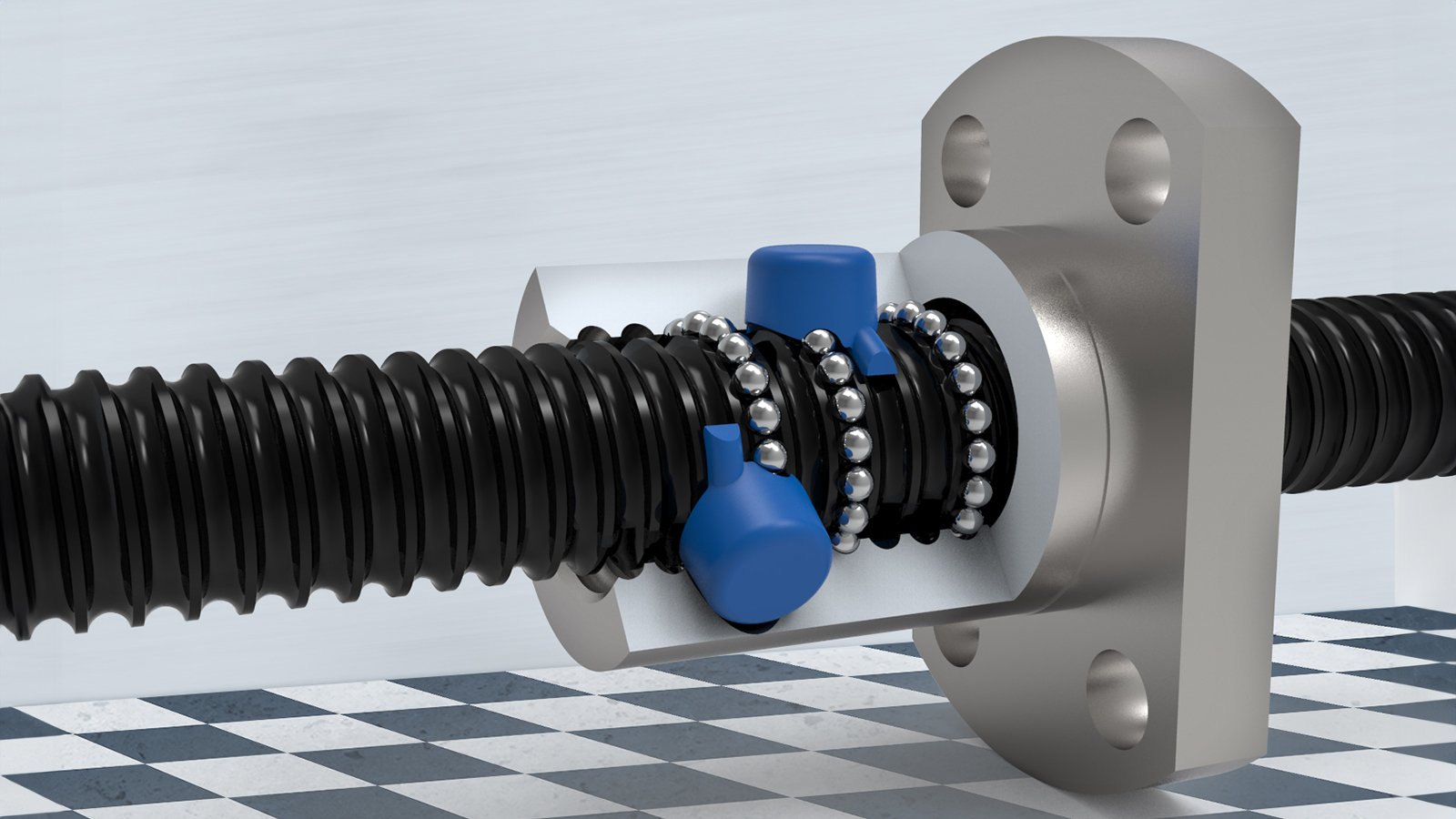

Before delving into their applications, let's grasp the fundamentals of ball screws. At their core, ball screws are mechanical devices designed to convert rotary motion into linear motion with high efficiency and precision. They consist of three main components:

- Screw Shaft: The threaded shaft that rotates to drive linear motion.

- Nut: The housing that contains the ball bearings and fits onto the screw shaft.

- Ball Bearings: Recirculating ball bearings within the nut that facilitate smooth and efficient linear motion.

The operation is simple yet brilliant: as the screw shaft rotates, the ball bearings within the nut recirculate in a helical groove, converting the rotary motion into linear motion. This mechanism reduces friction and provides high mechanical efficiency, making ball screws an ideal choice for precision motion systems.

Advantages of Ball Screws

Now, let's explore some of the key advantages that make ball screws indispensable in precision motion applications:

-

High Precision: Ball screws offer exceptional accuracy and repeatability, making them ideal for applications where precision is paramount. Compared to other mechanical transmission methods, the reduction in backlash ensures precise positioning.

-

Efficiency: Ball screws are highly efficient, converting a significant portion of input energy into linear motion. This efficiency translates to reduced power consumption and heat generation.

-

Low Friction: The recirculating ball bearings reduce friction, resulting in smoother and quieter operation. This characteristic is valuable in applications where noise reduction is critical.

-

High Load Capacity: Ball screws can handle high axial loads, making them suitable for applications that require both precision and substantial force, such as industrial automation and robotics.

-

Longevity: Properly maintained ball screws have a long service life, contributing to cost-effectiveness over the long term.

Applications of Ball Screws in Precision Motion Systems

Now that we understand the advantages of ball screws let's explore their diverse range of applications in precision motion systems:

-

CNC Machine Tools: Ball screws are the backbone of CNC (Computer Numerical Control) machine tools, including milling machines, lathes, and machining centers. They provide the accuracy and rigidity necessary for precision machining operations.

-

Medical Devices: In medical devices like robotic surgery systems, ball screws enable precise and steady movement for delicate procedures, improving patient outcomes.

-

Semiconductor Manufacturing: The semiconductor industry relies heavily on ball screws for wafer handling, precision alignment, and accurate positioning in the manufacturing process.

-

Aerospace and Defense: Ball screws play a vital role in aerospace applications, including aircraft control surfaces, missile guidance systems, and telescope positioning for satellites.

-

Laboratory Automation: In laboratory automation systems, such as liquid handling robots and spectrometers, ball screws ensure precise sample handling and measurements.

-

3D Printing and Additive Manufacturing: Ball screws are integral to the precise movement of the print head or build platform in 3D printers, ensuring the creation of intricate and accurate parts.

-

Robotics: Robotic arms and manipulators use ball screws to achieve precise movement and positioning in tasks such as pick-and-place operations and assembly.

-

Automotive Manufacturing: In automotive assembly lines, ball screws are employed for tasks like welding, painting, and chassis assembly, ensuring quality and consistency.

Calculating Ball Screw Performance

In precision motion applications, calculating the performance of a ball screw is crucial to achieving desired results. Several factors come into play when determining the suitability of a ball screw for a specific application:

-

Lead: The lead is the distance the nut advances with one complete revolution of the screw shaft. It determines the linear speed of the system.

-

Pitch Diameter: The pitch diameter of the screw affects its mechanical advantage and load-carrying capacity.

-

Backlash: Backlash refers to the clearance or lost motion between the nut and screw. Minimizing backlash is essential for precision.

-

Efficiency: The efficiency of a ball screw is the ratio of output motion to input motion. It is typically very high, but it's essential to consider it in calculations.

-

Load Capacity: The maximum axial load the ball screw can handle without failure is a critical parameter to ensure safety and reliability.

-

Speed: The maximum rotational speed of the screw and nut assembly must be within acceptable limits to prevent excessive wear and vibrations.

-

Lubrication: Proper lubrication reduces friction, wear, and heat generation.

In the realm of precision motion systems, ball screws are the unsung heroes, quietly enabling advancements in fields as diverse as manufacturing, medicine, and aerospace. Their ability to deliver high precision, efficiency, and reliability makes them a staple choice for engineers and designers striving to achieve unparalleled accuracy and control.

Understanding the science and advantages of ball screws is paramount when choosing the right solution for your application. By harnessing the power of ball screws, engineers continue to push the boundaries of what's possible in the world of precision motion, shaping industries and improving lives in the process.