Top 15 Acme Screw and Lead Screw Questions

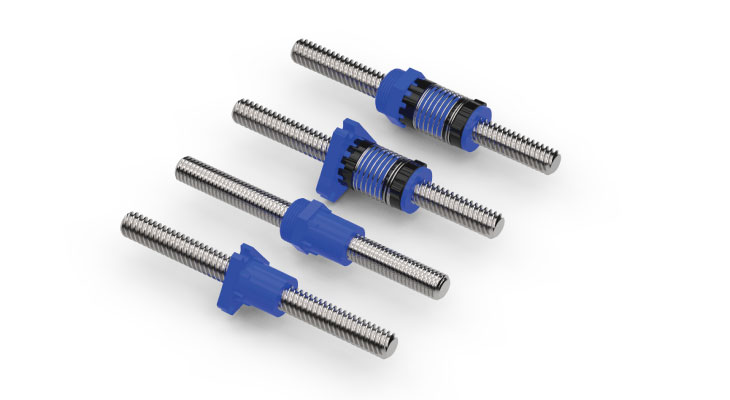

Acme Screw and Lead Screw Products

Acme screws convert rotary motion into linear motion by turning either the screw or the nut. Lead screws and nuts are highly customizable. Helix Linear offers a custom shop where engineers and manufacturers can use the most extensive collection of options available to build the best lead screw to fit their needs.

1. Does Helix Offer Bellows Boots for Acme Screws and Trapezoidal Lead Screws?

Yes, Helix Linear Technologies offers bellows boots for all lead screws and ball screws. Bellows are a great accessory to a lead screw assembly that will be used in dirty environments. A bellows boot can be added to either side of the nut to cover the screw. A bellows cover typically adds 10% to the required screw length. Bellows' covers can be made from various materials that perform well in extreme temperatures or highly caustic environments.

2. Do Lead Screws and Nuts need to be Lubricated?

Yes, we offer high-quality lubricants for your acme screw application. We provide several greases designed for specific uses like military and aerospace, semiconductor, and medical applications. We also offer high-performance dry lubricants like our H10X™ PTFE coating and several different ceramic coatings for applications that need to be "clean."

3. What is the Difference Between Pitch and Lead?

Pitch is the measurable distance between screw grooves. Lead is the linear travel the nut makes per screw revolution. The pitch and lead are equal with single start screws. The pitch is ½ the lead in two start screws.

4. For Extra Strength, Should I Use an Extra Long Nut Instead of Standard Nuts?

In theory, yes, it would be better, but in practical terms, it wouldn't. The standard length nuts offered in the Helix Linear Technologies catalog offer the best price/performance ratio. When using extra-long nuts, special gauging and tooling are required for them to work correctly. Fit-up problems typically occur when using extra-long nuts, creating hot spots that can expand thermally under load and bind locally on the screw. However, larger diameters should be considered if capacity is a significant concern.

5. Are Alloy ACME Screws Better Than Medium and Low Standard Carbon Steel Screws?

The Alloy 4140 Heat Treated Lead Screw is favorable only with specific applications and is frequently "over specified." This is typically attributed to the fact that it is a trendy material for fastener threads and bolts. Numerous users specify Alloy 4140 HT with the intent of extending the screw's wear life. Still, the majority of screws are used with either plastic or bronze nuts. There is a significant hardness differential between these materials and all steels, meaning that the performance of the nut materials is not changed.

6. Are End Machining Services Offered at Helix Linear Technologies?

Yes. Helix Linear has a 40,000 sqft manufacturing facility in Cleveland, Ohio, with multi-axis CNC machines dedicated to machining lead screws and linear actuators. We can machine prototype lead screws quickly and we have the capacity to produce high volumes of screws.

7. What Materials are Used to Manufacture Helix Screw Products?

Helix Linear Technologies utilizes materials that efficiently produce superior thread finish while also integrating excellent machinability. Acme screws, Trapezoidal screws , and Hi-Lead screws: can be manufactured from low carbon alloy, high carbon heat-treated alloys, aluminum, titanium, bronze, plastic, and ceramic materials.

8. What are the "C" and "G" classes of Fit for Lead Screws?

The two classes of fit described in the ANSI standard for ACME screw threads are "Centralizing (C) "and "General Purpose (G)." The General Purpose fit allows the nut and screw contact interface to take place on the thread flanks while simultaneously providing clearance on the minor and major diameters. On the other hand, the Centralizing fit allows for contact on the major diameters while maintaining the same thread flank contact as the generalizing fit. There are minor differences between C and G when being used for applications solely of axial loading.

9. Are There Any Distinctions Between a Left or Right Handed Thread?

Typically, unless stated otherwise, lead screws are right-handed. There are occasions where left and suitable hand screws will be used simultaneously to permit travel in both directions concurrently. Helix Linear manufactures Twin-LeadTMscrews as a standard product in sizes from 2mm - 75mm diameters.

10. Is It Possible to Determine if a Lead Screw Is Ground and Rolled by Looking at It?

Yes, the simplest way to do so is by examining the lead screw's outer diameter. There may be a fold or line (known as the witness line or crest line) present where the material has been dislocated to form the screw. If so, then the lead screw is rolled.

11. How Often Should I Lubricate a Lead Screw?

Regularly checking for adequate lubrication amounts on a lead screw can help prevent premature wear and extend the life of the screw assembly. The lead screw must remain lubricated. If there is a lack of lubrication on the screw, additional quantities should be applied. Lubrication frequencies are very application-specific and should be established to eliminate the chance of running a screw assembly without lubricants.

12. How Do I Decide Which Type of Screw Product to Use? Acme vs. Ball Screw for My Application?

Screw selection is dependent on many factors that include but are not limited to application load, desired speed, accuracy/repeatability requirements, and application environment. For help in selection, don't hesitate to contact The Helix Application Engineering Team or visit our Lead Screw CAD Configurator to build a custom screw for our team to evaluate.

13. Can Acme Screws be Used in Vertical Applications Without Back Driving?

Yes, lead screws can be used in vertical applications as long as the screw efficiency is below 40% and the screw does not experience any vibration. All applications moving people and flight-critical surfaces on airplanes and UAVs should be reviewed by Helix Application Engineers.

14. Are Lead Screw Products Able to be Used in Harsh Environments?

Helix PowerAc™ acme screws and nuts do not utilize any rolling elements and perform well in harsh environments. Lead screws perform well in paper, material handling, wood and metal cutting, and food processing.