Acme Screws and Looney Tunes Cartoons: Perception and Precision

When people hear the word Acme, many conjure up the image of the Acme brand products used by Wile E. Coyote in his attempts to catch his desert nemesis, the roadrunner. If you reflect on the episodes (and care to admit that you still think about the cartoons you watched as a child), misuse and misapplication of the products were Coyote's downfall, not the Acme products themselves.

While Acme products may have had a generic connotation and produced substandard results, as demonstrated in Coyote's experience, Acme is the opposite as we know it today.

What does Acme mean?

Merriam Webster's dictionary defines Acme as:

"Something or someone that represents the perfection of the thing expressed," and "the highest point or stage."

Acme | Definition of Acme by Merriam-Webster. https://www.merriam-webster.com/dictionary/acme

Today's advanced manufacturing technology of Acme screws provides both high precision and impeccable quality in linear motion applications.

The History of Lead Screws

Lead screws have been used in simple machines very early in recorded history. Acme screws are believed to have been developed in the late 1800s to replace a square thread screw-in power transmission. In an Acme lead screw, the thread angle acts as a wedge, so a relatively small movement of the screw creates a considerable force on the nut through its mechanical advantage. The Acme design was preferred because the thread angle was conducive to improved manufacturing processes. The Acme thread is more accessible to machine or roll than a square thread without detriment to efficiency and strength. The quality of acme screws today, especially precision rolled or ground, can be made to the highest standards of accuracy and finish.

Acme Screw Terminology

The term "Acme screw" can sometimes be oversimplified, only implying that a lead screw has a 29-degree thread angle. While the angle is the defining feature of the Acme thread, there is much more to be considered when using an acme lead screw in precision linear motion applications, including thread class and accuracy. Acme screws are a specific type of lead screw consisting of a thread angle of 29-degrees (flank angle14.5 degrees). The standard acme form has a thread height that is half the pitch. A Stub Acme thread has the same 29-degree angle but a truncated thread height 1/3 the pitch.

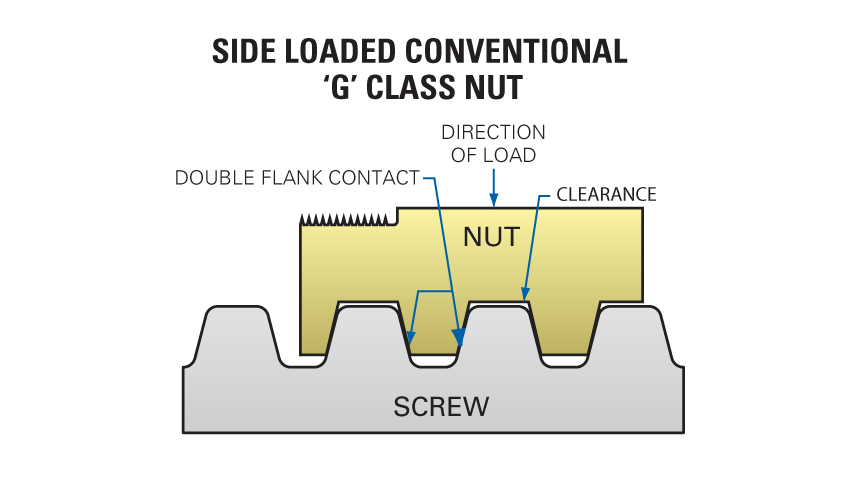

An acme screw can be manufactured to a G or C class thread fit. The "G" or general-purpose fit is designed such that the nut threads contact the screw threads at the pitch diameter when a radial force is applied.

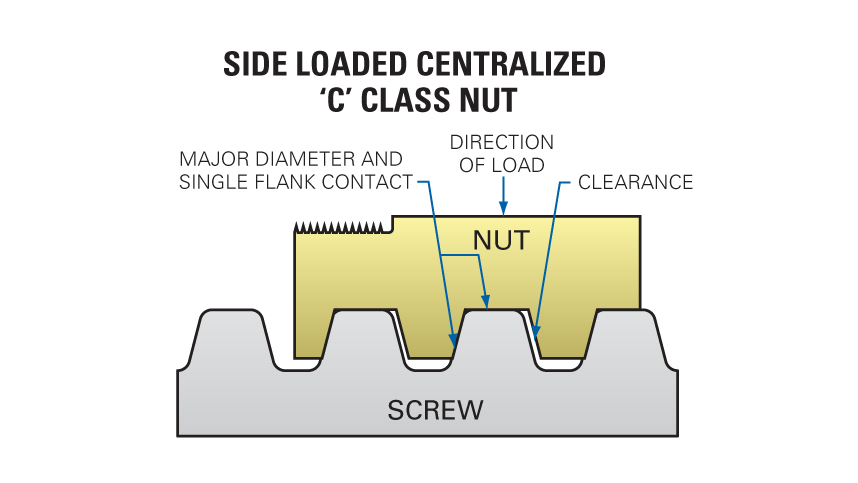

A "C" or centralizing fit is designed so that the nut threads contact the peak or top of the screw threads when a radial force is applied.

Acme screws are the most common lead screws, but not all lead screws are acme screws. Lead screws can be trapezoidal -- having a thread angle of 30 degrees. Or, they can have a 40-degree angle and be referred to as a modified acme. They can be machined, rolled, or ground to lead accuracy greater than .0003"/inch and surface finish better than 16 micro-inches.

Stainless steel acme screws are in applications when corrosion resistance is necessary. Alloy steel lead screws such as 4140 are used when stainless may not be required and can be hardened for higher tensile strength and wear resistance with metal nuts. When non-stainless materials are used, the acme screws are typically treated with a coating or finish to help prevent oxidation.

How to Size an Acme Screw

Considerations such as loads, speeds, stroke length, efficiency, positional accuracy, duty cycle, and life are all factors for sizing and selecting an acme lead screw for its proper use and application. Longer acme screw leads will provide greater efficiency, while shorter acme screw leads will supply a better mechanical advantage. Correct lead screw size selection is based on the diameter of the lead screw and the material of the nut. Proper sizing is necessary to achieve the required dynamic and static load rating based on the thread size and engagement. The diameter of the lead screw should be considered so it is adequate compared to the overall length, and the ends should be supported properly to prevent column bending. The pitch or lead in multi-start acme screws is selected based on the resolution accuracy required, and to maintain linear speeds that ensure RPMs are kept below the critical speed of the shaft.

Learn more about Lead Screw Calculators HERE.

Acme screws are the preferred choice for precise linear motion applications no matter the form or style required. Typical applications include lab automation, medical devices, aerospace, machine tools, and numerous industrial applications. To avoid the improper Acme product selection that befell our friend the Coyote, consult with an application engineer to guide you through sizing and selecting the best acme lead screw assembly for your linear motion project.