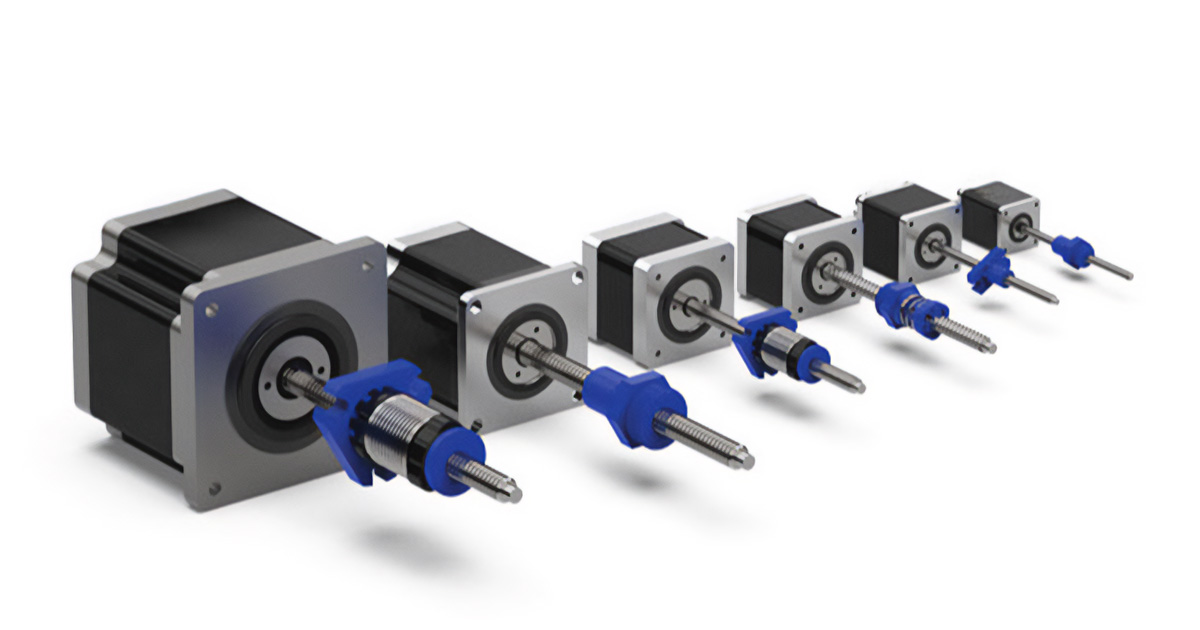

Get Moving with a Precision Linear Actuator

-

Eliminate costly couplings and support bearings to lower system cost, and provide for more compact, stiffer, easy to mount and align assemblies

-

Stepper motors' high torque at low speeds can eliminate gearboxes for precision positioning accuracy

-

Selecting the appropriate lead screw may provide self-braking in many applications, eliminating a costly brake assembly

-

Stepper motors are also inexpensive to control, and there are many low-cost drives available to power and control stepper motors

-

Optional motor encoders are available - fastened to the back for closing the loop, further enhancing system accuracy

Laser Welding

At Helix, we utilize laser welding to attach the lead screws and ball screws to the hybrid stepper motors. The stepper motor is beefed-up with deep groove ball bearings to maximize thrust loads and rigidity. Welded assemblies provide better alignment, don't come apart, and are lower cost. Helix has pioneered laser welding expertise to provide accurate, strong, and reliable welds.

Helix lead screws are PTFE coated in a computer-controlled environment ensuring uniform coating, long life, and the smoothest operation. Having this facility in-house also provides prompt delivery and total quality control. We also manufacture our lead screws and injection mold our lead screw nuts in a state-of-the-art manufacturing plant using the latest technology to ensure the highest quality.