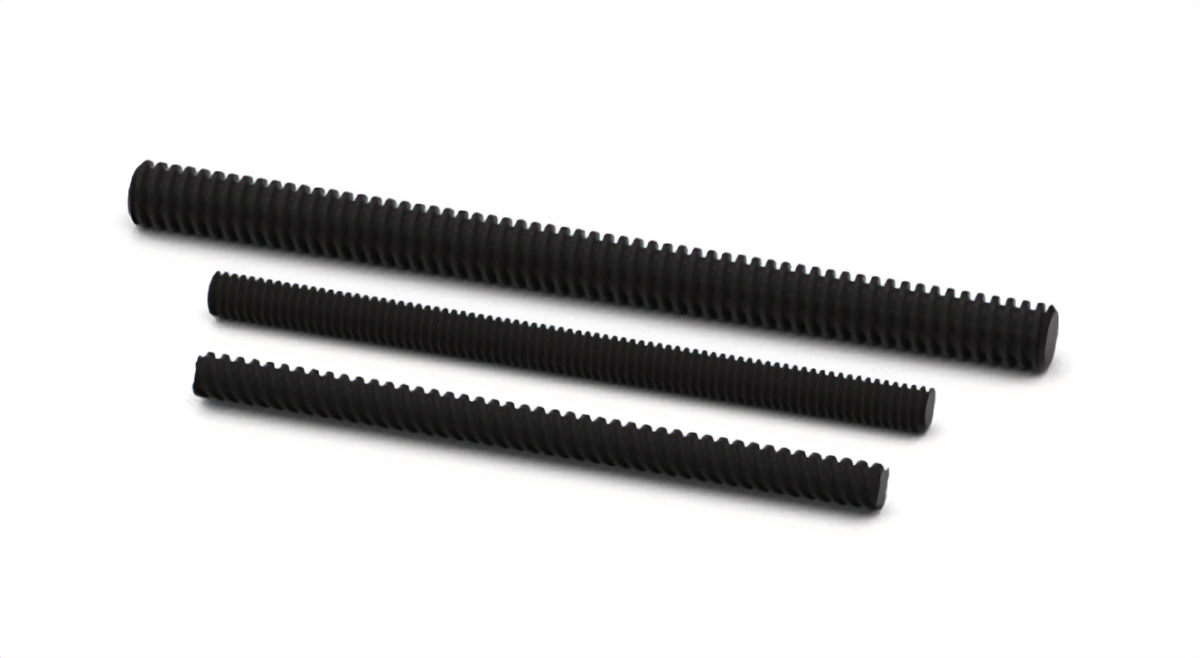

Precisely Why Your Lead Screw Coating Matters in Your Applications

Coatings are made up of resin, additives, and a liquefying agent that’s either “water-based” or “solvent-based.” Water-based coatings and solvent-based coatings have distinct purposes that depend on your needs. One coating may work better for lead screws under mild weather conditions. Another coating may fit a job that involves much heavy handling.

Water or Solvent Based?

According to a blog post by US Coatings, Water-based coatings are present on items close to people. Household paints, for instance, are most likely water-based. Projects, where people are working in confined spaces can involve items covered in a water-based coating. This type of coating doesn’t necessarily mean zero solvents.

Solvent-based coatings are intended to withstand certain climates and more wear and tear than their water-based counterparts. If you’re working in a very humid environment, choosing materials with a water-based coating may prevent the water from evaporating. In a video by The Cement Store, they point out solvent-based sealers create a continuous film that can prevent moisture from seeping in.

This is where Helix’s PTFE coating comes in.

PTFE Coating

The Helix Linear PTFE coating is hard and solvent-based. It doesn’t flake or chip. The PTFE coating creates a permanent and low friction surface from lead screw to nut. Our PTFE coating is resistant to oils, chemicals, cutting fluids, coolants, and is less susceptible to peeling off in harsh environments or installations.

Some soft PTFE coatings will transfer particles from a lead screw to nut. The Helix PTFE coating is designed to stay on the lead screw, which provides longer life since nut wear is significantly reduced. Our testing consistently shows that nut life increases by 8 to 10 times without added grease or lubricants. With our coating, the friction coefficient is cut from .15 to .08 on a stainless steel screw. This increases efficiency by 5% over an uncoated screw.