The Acme thread form, established over 100 years ago, replaced square thread screws. Square thread screws had straight-sided flanks and were difficult to manufacture, so that makes the Acme thread form a great improvement. There are three main classes of Acme thread types:

- General Purpose – This thread form has a nominal depth of thread of 0.50 x pitch and has a 29° included thread angle. Some Helix sizes have 40° included angle. Trapezoidal thread forms have a 30° included thread angle.

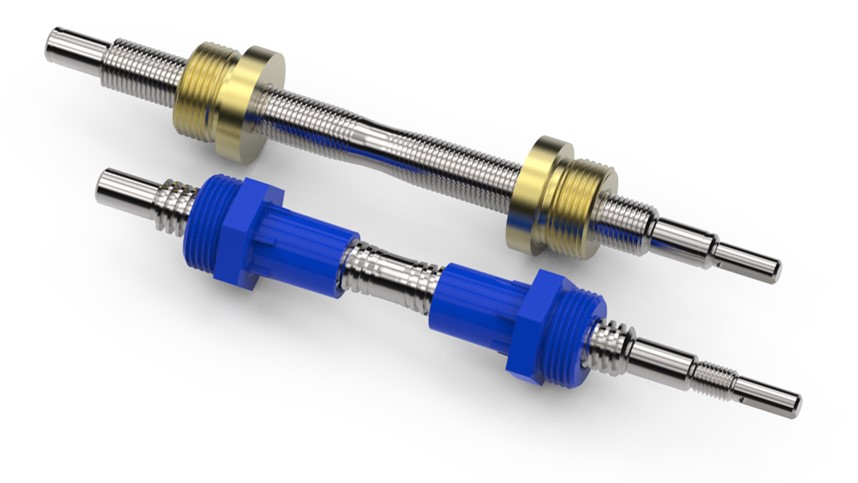

- Centralizing – Centralizing threads are manufactured with tighter tolerances and reduced clearance on the major diameter.

- Stub Acme – These threads follow the same basic design, but have a thread depth less than one half the pitch

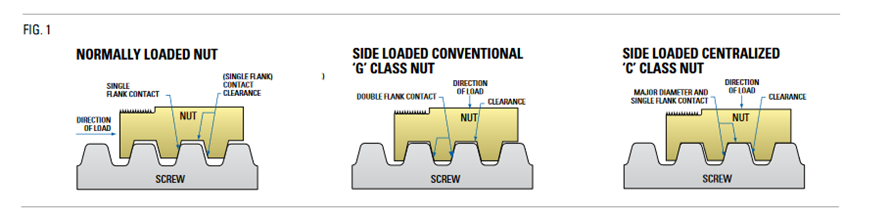

If an acme nut is side loaded with a radial load, a “G” class will “wedge” when the nut thread flanks come in contact with the screw thread flanks. To prevent wedging, less clearance and tighter tolerances are allowed between the major diameter of the nut and the major diameter of the screw.

A word of caution: Although a side load will not cause a centralizing thread to wedge, the nut is not designed to operate with a side load such as a pulley, drive belt, etc.

Have a question that's not answered here? Call us. Our number is 1-855-435-4958.