Factory Automation

Driving Manufacturing Excellence: Embracing linear motion in a Globalized Market.

In factory automation, lead screws, ball screws, and linear actuators are fundamental components that drive efficiency, precision, and safety across various applications. Let's explore how these technologies are utilized in robots, feeder technology, dispensing automation, laser processing applications, industrial automation systems, inspection and test systems, elevators, automated assembly systems, and safety platforms.

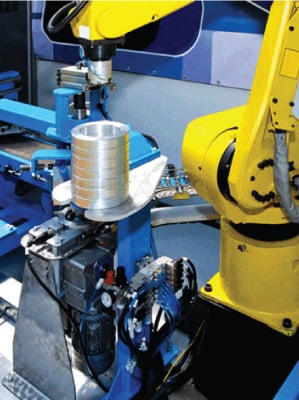

Robots

Robots

Lead screws, ball screws, and linear actuators are integral to the movement and functionality of industrial robots. Lead screws enable precise linear motion in robotic arms, facilitating accurate positioning and manipulation of objects within manufacturing processes. Ball screws provide smooth and efficient rotational movement in robot joints, ensuring fluid and precise articulation for complex tasks. Linear actuators drive vertical and horizontal movement in robot platforms, allowing for versatile and adaptable operation across diverse production environments.

Feeder Technology

Lead screws and linear actuators play critical roles in feeder technology, which is essential for precise and controlled material handling in automated assembly lines. Lead screws facilitate smooth and accurate advancement of components along feeder tracks, ensuring consistent feeding rates and minimizing production errors. Linear actuators enable the controlled adjustment of feeder mechanisms, allowing for precise positioning and alignment of materials for seamless integration into manufacturing processes.

Dispensing Automation

In dispensing automation applications, such as adhesive or sealant dispensing systems, lead screws, ball screws, and linear actuators are utilized for precise material deposition. Lead screws provide controlled linear motion for precise material flow rates and bead widths, ensuring accurate application and uniform coverage. Ball screws enable precise rotational movement in dispensing nozzles, facilitating accurate positioning and dispensing of materials onto workpieces. Linear actuators drive the vertical and horizontal movement of dispensing heads, allowing for flexible and adaptable dispensing patterns to meet diverse production requirements.

Laser Processing Applications

Lead screws, ball screws, and linear actuators are essential components in laser processing applications, including laser cutting, welding, and marking systems. Lead screws facilitate precise linear motion of laser heads or workpieces, ensuring accurate positioning and alignment for precise laser beam delivery. Ball screws provide smooth and precise rotational movement in laser positioning systems, enabling high-speed and high-accuracy laser processing. Linear actuators drive the vertical and horizontal movement of laser platforms, allowing for versatile and adaptable laser processing across various materials and geometries.

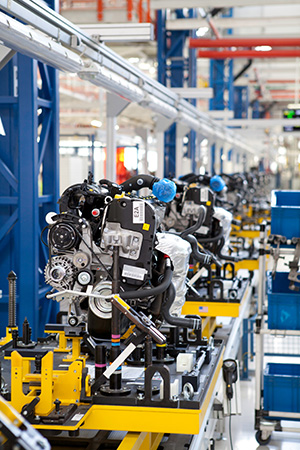

Industrial Automation Systems

Industrial Automation Systems

Lead screws, ball screws, and linear actuators are fundamental to industrial automation systems, which encompass a wide range of manufacturing and assembly processes. Lead screws enable precise linear motion in conveyor systems, material handling equipment, and robotic arms, ensuring efficient and reliable production workflows. Ball screws provide smooth and precise rotational movement in machinery and equipment, facilitating accurate positioning and operation in industrial processes. Linear actuators drive vertical and horizontal movement in automated machinery, allowing for flexible and adaptable operation to meet changing production demands.

Inspection and Test Systems

In inspection and test systems, precision and accuracy are paramount for ensuring product quality and compliance with specifications. Lead screws, ball screws, and linear actuators are utilized in positioning stages, measurement devices, and testing equipment to enable precise movement and positioning of test probes or workpieces. Lead screws facilitate controlled linear motion for accurate scanning and measurement operations, ensuring reliable inspection results. Ball screws provide smooth and precise rotational movement in positioning systems, allowing for accurate alignment and orientation of test components. Linear actuators drive vertical and horizontal movement in inspection systems, enabling versatile and adaptable testing procedures to meet diverse quality assurance requirements.

Elevators

Lead screws, ball screws, and linear actuators are essential components in elevator systems, which rely on precise motion control for safe and efficient vertical transportation. Lead screws facilitate controlled linear motion in elevator carriages, ensuring smooth and reliable travel between floors. Ball screws provide smooth and efficient rotational movement in elevator drive mechanisms, enabling precise control of lift speed and acceleration. Linear actuators drive vertical movement in elevator doors, ensuring precise opening and closing operations for passenger safety and convenience.

Automated Assembly Systems

In automated assembly systems, lead screws, ball screws, and linear actuators are crucial for precise positioning and assembly of components. Lead screws enable controlled linear motion in assembly line conveyors and robotic arms, facilitating accurate placement and alignment of parts during assembly processes. Ball screws provide smooth and precise rotational movement in assembly fixtures and tooling, allowing for accurate tightening of fasteners and joining of components. Linear actuators drive vertical and horizontal movement in assembly platforms, enabling flexible and adaptable assembly procedures to accommodate various product configurations and production requirements.

Safety Platforms

Lead screws, ball screws, and linear actuators are utilized in safety platforms and access systems to ensure secure and reliable operation in industrial environments. Lead screws facilitate controlled linear motion in platform lifts and safety gates, allowing for safe and convenient access to elevated work areas. Ball screws provide smooth and precise rotational movement in platform positioning systems, enabling accurate deployment and retraction of safety barriers. Linear actuators drive vertical and horizontal movement in safety enclosures and guarding systems, ensuring efficient and reliable protection of personnel and equipment in hazardous work environments.

Lead screws, ball screws, and linear actuators are indispensable components that drive efficiency, precision, and safety in various factory automation applications. Their versatility, reliability, and precision control capabilities make them essential for optimizing production workflows, ensuring product quality, and enhancing workplace safety in modern manufacturing environments.

Speak to an Application Engineer

Our application engineers are here to help you plan, customize and select the optimal linear motion components for your additive manufacturing application.

Our Products

Helix Linear Technologies offers a wide range of linear motion products that are designed to make your next food and beverage handling application a success. Not sure what you need? No problem. We're here to help guide you every step of the way.

Ball Screw Assemblies

Linear Actuators

Linear Guidance

Downloads

Inch Ball Screw Catalog

Inch Ball Screw Catalog

Find precision and performance in the Helix Linear Ball Screw Catalog.

Lead Screw Catalog

Lead Screw Catalog

Get precision motion solutions with the Helix Linear Lead Screw Catalog.

PRA Actuator Catalog

PRA Actuator Catalog

Discover innovation with the Helix Linear Profile Rail Actuator Catalog.